Steel dowel pins are essential precision components used for alignment, positioning, and load transfer in mechanical assemblies. They are widely applied in industries such as automotive, industrial equipment, tooling, and precision assemblies where dimensional accuracy and repeatability are critical.

This article explains different types of steel dowel pins, including alloy steel dowel pins, hardened steel dowel pins, threaded, hollow, and grooved designs, as well as how advanced Swiss machining supports consistent quality from professional steel dowel pins suppliers.

What Are Steel Dowel Pins?

Steel dowel pins are cylindrical fastening components designed to precisely align mating parts. Unlike bolts or screws, dowel pins focus on positioning accuracy rather than clamping force. Their tight tolerances allow repeatable assembly and reliable load distribution.

Depending on application requirements, dowel pins can be produced in various steel grades, hardness levels, and structural designs to meet strength, wear resistance, and installation needs.

Alloy Steel Dowel Pins for High-Strength Applications

Alloy steel dowel pins are commonly used when higher strength and fatigue resistance are required. Compared to low-carbon steel, alloy steel offers improved mechanical properties, making it suitable for:

High-load assemblies

Repeated assembly and disassembly

Tooling and fixture applications

Precision mechanical systems

Through controlled heat treatment and precision machining, alloy steel dowel pins achieve consistent hardness and dimensional stability, even under demanding operating conditions.

Hardened Steel Dowel Pins and Heat Treatment

Hardened steel dowel pins undergo heat treatment processes to improve wear resistance and service life. Hardening is especially important in applications involving:

Precision machining followed by controlled hardening ensures the pins maintain tight tolerances while achieving the required surface hardness.

To achieve this balance, manufacturers often rely on Swiss machining services, which are ideal for producing high-precision cylindrical components with excellent repeatability.

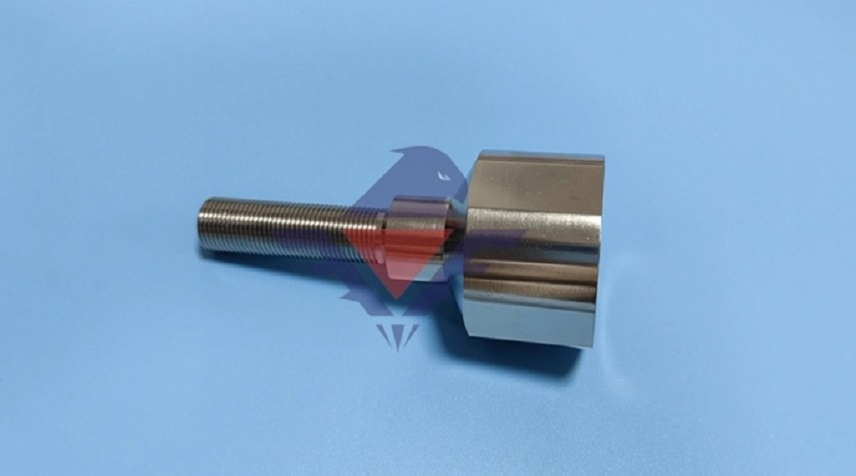

Threaded Dowel Pins Steel Designs

Threaded dowel pins steel variants include internal or external threads that allow easier installation and removal. These designs are commonly used in:

Swiss-style CNC machining enables precise control of both the dowel diameter and the threaded features, ensuring accurate alignment without compromising structural integrity.

Hollow Steel Dowel Pins for Weight Reduction

Hollow steel dowel pins feature an internal bore that reduces weight while maintaining external alignment accuracy. This design is beneficial in applications where:

Weight reduction is critical

Thermal expansion must be managed

Controlled flexibility is required

Producing hollow dowel pins requires stable machining processes to ensure concentricity and wall thickness consistency—an area where Swiss machining excels.

Grooved Dowel Pins Steel for Secure Fit

Grooved dowel pins steel designs include longitudinal or spiral grooves that improve retention during press-fit installation. The grooves allow material displacement, creating a secure mechanical lock without additional fasteners.

These pins are often used in high-vibration environments or assemblies requiring permanent positioning.

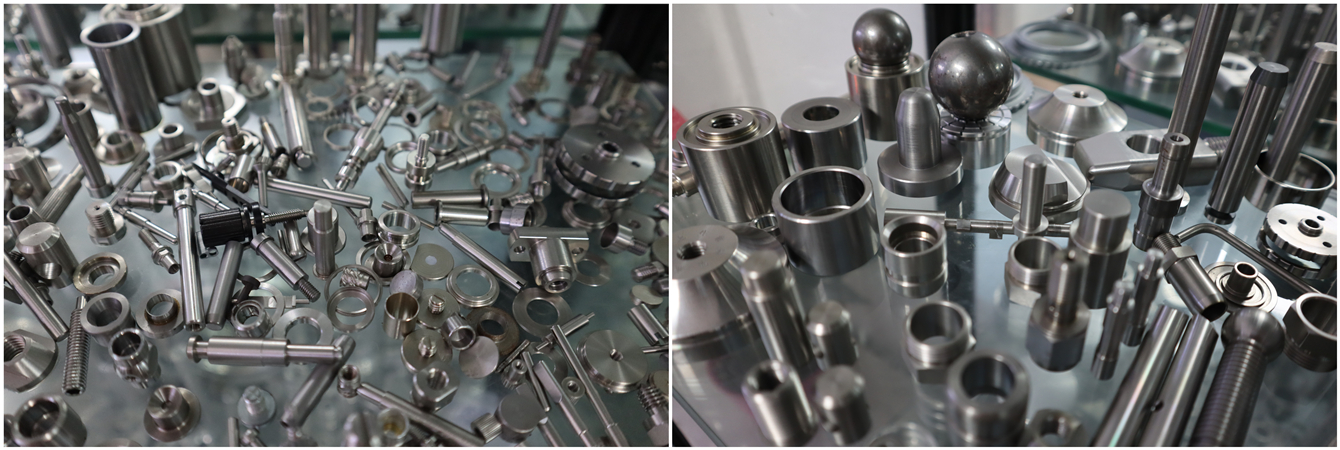

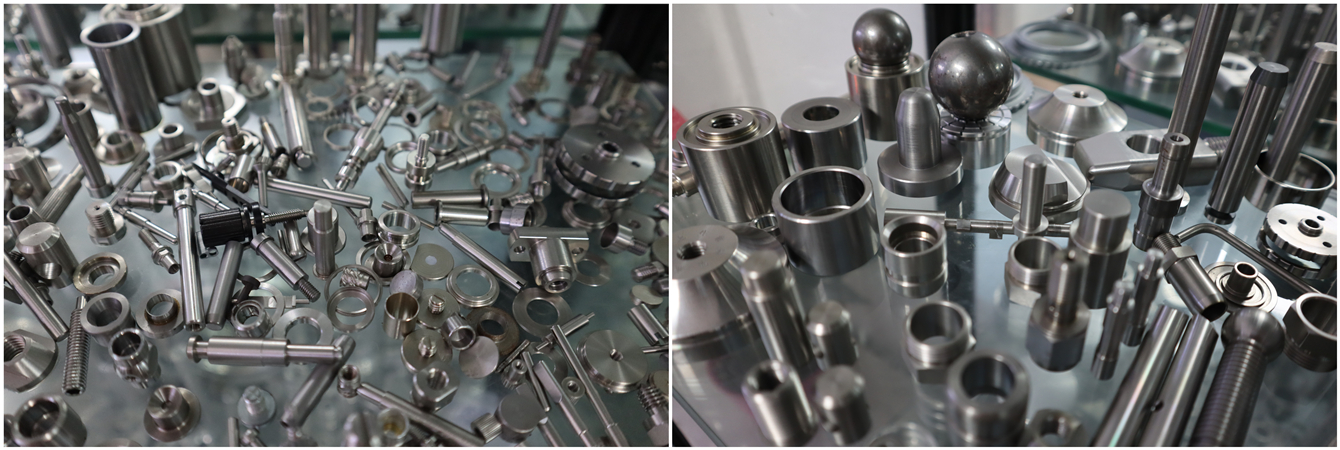

Precision Manufacturing of Dowel Pins and Shafts

Dowel pins demand extremely tight tolerances, often measured in microns. Precision CNC and Swiss machining are essential to achieve:

Manufacturers specializing in pins and shafts machining are better equipped to meet these requirements.

Explore precision production capabilities for pins and shafts used in demanding mechanical applications.

Choosing Reliable Steel Dowel Pins Suppliers

When evaluating steel dowel pins suppliers, consider the following factors:

Machining Capability – Swiss machining experience with tight tolerances

Material Control – Alloy steel grades and heat treatment expertise

Quality Systems – Inspection, traceability, and consistency

Customization – Ability to produce threaded, hollow, or grooved designs

Scalability – Support for both prototypes and production volumes

Partnering with a precision-focused manufacturer reduces risk and ensures long-term performance.

Conclusion

From alloy steel dowel pins and hardened steel dowel pins to threaded, hollow, and grooved designs, steel dowel pins play a vital role in precision assemblies. Their performance depends not only on material selection but also on machining accuracy and process control.

By working with experienced steel dowel pins suppliers that leverage advanced Swiss machining services and specialize in pins and shafts manufacturing, manufacturers can achieve consistent quality, reliability, and repeatable performance across applications.