The medical industry relies on precision machined medical parts to ensure safety, performance, and regulatory compliance. From diagnostic equipment to surgical instruments and implantable devices, CNC machining plays a critical role in manufacturing high-accuracy medical components.

This article explains how precision machining for medical devices works, what CNC capabilities are required, and why specialized medical CNC machining services are essential for modern medical manufacturing.

What Are Precision Machined Medical Parts?

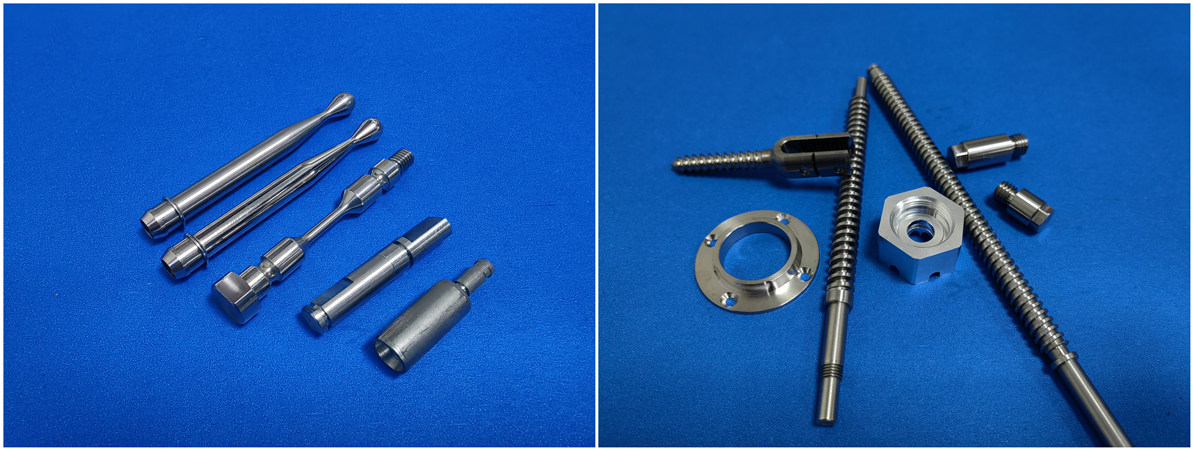

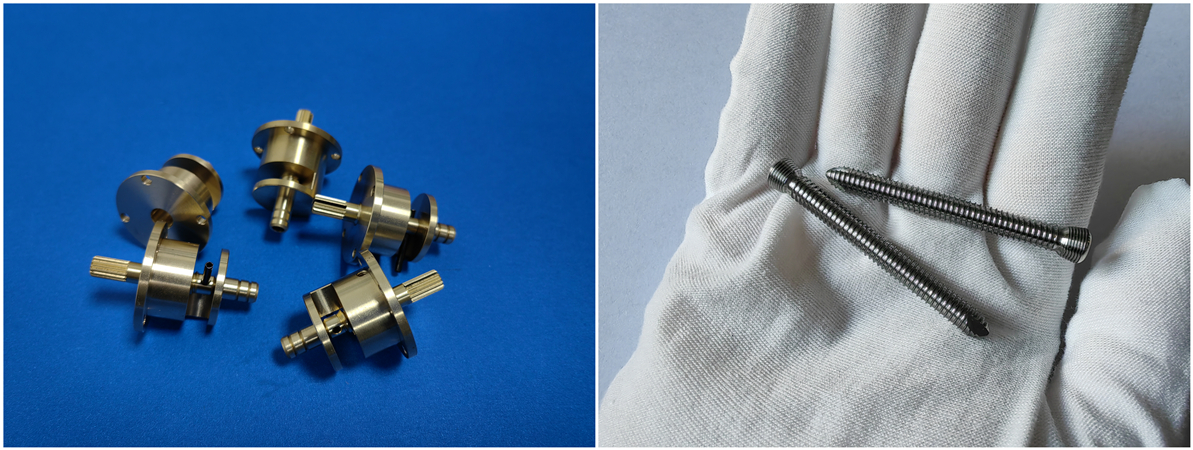

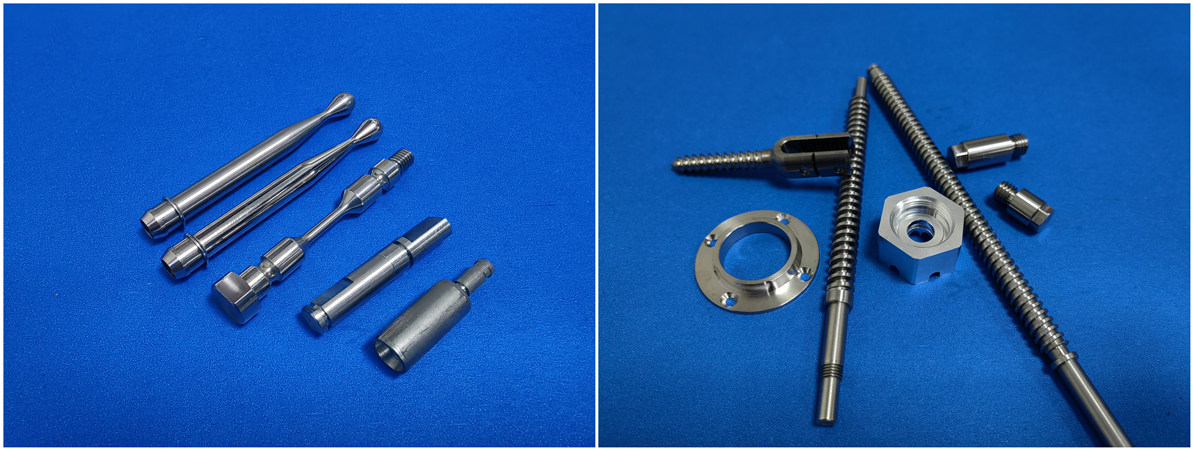

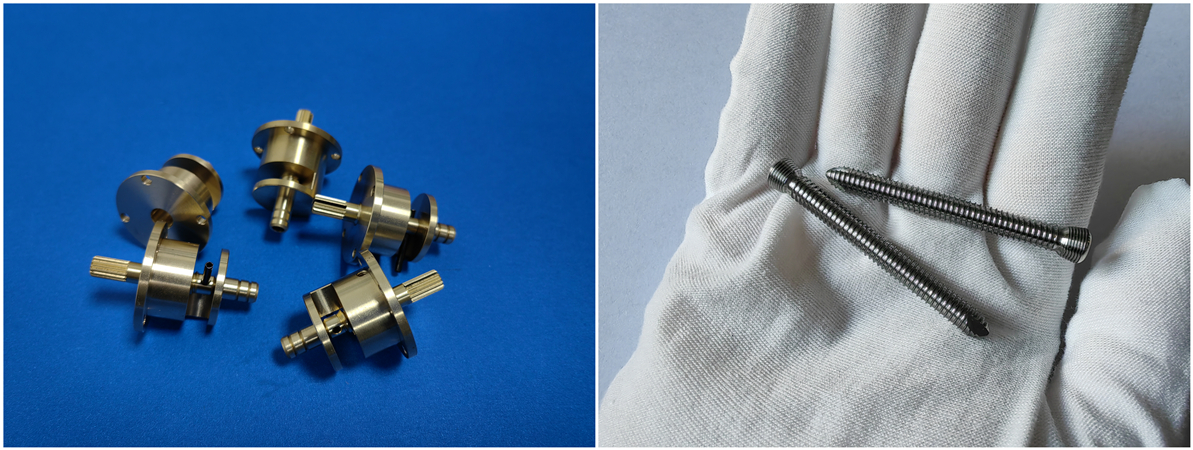

Precision machined medical parts are components manufactured with extremely tight tolerances, consistent repeatability, and controlled surface finishes. These parts are commonly used in:

Medical and surgical instruments

Diagnostic and monitoring equipment

Implantable and non-implantable medical devices

Miniature and complex medical assemblies

Because of the strict performance requirements, most medical manufacturers depend on advanced CNC machined parts for medical applications rather than conventional machining methods.

Precision Machining for Medical Devices Explained

Precision machining for medical devices involves specialized CNC processes designed to meet medical-grade standards. These processes focus on:

Micron-level tolerances

Burr-free and clean machining

Stable dimensional consistency

Documentation and traceability

To achieve these requirements, manufacturers often partner with suppliers that offer dedicated medical precision machining capabilities.

Learn more about medical precision machining designed for regulated medical applications.

CNC Machining for the Medical Industry

CNC machining for the medical industry supports a wide range of production needs, from rapid prototyping to medium-volume manufacturing. Compared with other manufacturing methods, CNC machining provides:

High dimensional accuracy

Flexibility across materials

Excellent repeatability for regulated components

Scalability for production growth

As a result, CNC machining for medical devices is widely used for both functional prototypes and production-ready parts.

Medical CNC Machining Services and Capabilities

Professional medical CNC machining services combine advanced equipment with quality-focused processes. Typical capabilities include:

CNC milling and turning for medical components

Swiss machining for small and high-precision parts

5-axis machining for complex medical geometries

Secondary finishing and inspection services

These services are essential for producing CNC machined parts for medical applications that require consistent performance and compliance.

For OEMs seeking stable quality and engineering support, working with an experienced medical machining partner is critical.

Explore advanced precision medical Swiss machining services for complex medical components.

Medical Plastics Machining in CNC Manufacturing

In addition to metals, medical plastics machining plays an increasingly important role in medical device manufacturing. CNC machining is commonly used to produce plastic medical parts from materials such as:

CNC machining allows tight tolerances and excellent surface quality without the high tooling costs associated with injection molding, especially for low- to medium-volume medical production.

Many precision medical components combine both metal and plastic parts, making integrated CNC capabilities highly valuable in the medical supply chain.

Applications of CNC Machined Parts for Medical Devices

CNC machined parts for medical devices are widely used across different medical applications, including:

Surgical tool components

Diagnostic device housings

Implantable device components

Precision connectors, pins, and shafts

These applications require a balance of accuracy, material performance, and manufacturing consistency—making CNC machining one of the most reliable production methods for the medical industry.

Why Precision CNC Machining Matters in Medical Manufacturing

Even minor dimensional variations can affect device performance, assembly fit, or regulatory approval. That’s why precision machining for medical devices emphasizes:

Controlled machining environments

In-process inspection

Clean handling of medical components

Documented quality systems

Manufacturers that invest in specialized medical CNC machining services reduce risk while improving product reliability and time to market.

Discover how precision medical machining supports demanding medical device requirements.

Conclusion

From metals to advanced plastics, precision machined medical parts are essential to modern medical manufacturing. With the growing complexity of medical devices, CNC machining for the medical industry continues to be a preferred solution for achieving accuracy, compliance, and scalability.

By partnering with an experienced provider of medical CNC machining services, medical device manufacturers can ensure consistent quality and long-term production success.