The medical device industry demands uncompromising accuracy, consistency, and compliance. From surgical tools to diagnostic equipment, every component must meet strict regulatory and performance requirements. This is why medical device precision machining has become a critical manufacturing solution for OEMs, contract manufacturers, and healthcare technology companies.

In this article, we explore how medical device CNC machining, medical device contract machining, and specialized medical device machining manufacturers support the production of high-quality medical instruments and surgical components.

What Is Medical Device Precision Machining?

Medical device precision machining refers to the manufacturing of medical components with extremely tight tolerances, repeatable accuracy, and controlled processes. These components are often used in applications where reliability directly affects device performance and patient safety.

Precision machining for medical devices typically involves:

Tight dimensional tolerances

High surface finish requirements

Consistent process control

Full inspection and documentation

To meet these standards, manufacturers rely on advanced CNC technologies and specialized quality systems.

Learn more about medical precision Swiss machining designed for regulated medical applications.

Medical Device CNC Machining Capabilities

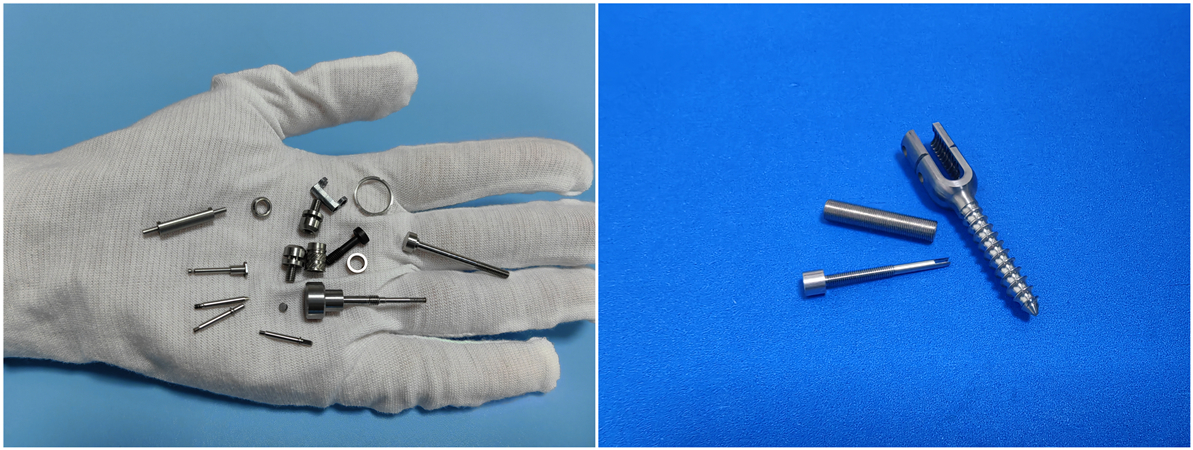

Medical device CNC machining enables manufacturers to produce complex geometries, miniature components, and high-precision features that are difficult to achieve with other processes.

Common CNC capabilities for medical devices include:

CNC milling and turning for housings and structural components

Swiss machining for small, intricate parts

5-axis machining for complex medical geometries

Secondary operations such as deburring and surface finishing

These processes are widely used in the production of diagnostic devices, surgical tools, and precision medical assemblies.

Medical Device Contract Machining Explained

Many OEMs choose medical device contract machining to reduce production risk, control costs, and scale manufacturing efficiently. Contract machining partners provide specialized expertise without the need for in-house capital investment.

Key benefits of medical device contract machining include:

Access to advanced CNC and Swiss machining equipment

Scalable production from prototyping to volume manufacturing

Quality systems aligned with medical industry requirements

Engineering support for manufacturability and optimization

Experienced contract manufacturers help ensure consistency and compliance throughout the product lifecycle.

See how medical precision machining services support long-term medical device programs.

Choosing Medical Device Machining Manufacturers

Not all suppliers are equally qualified to support medical applications. Professional medical device machining manufacturers distinguish themselves through industry experience, controlled processes, and documented quality systems.

When evaluating a medical machining manufacturer, consider:

Proven experience with medical device components

Capability to machine complex and miniature parts

Process control and inspection methods

Material knowledge for medical-grade alloys and plastics

Clear communication and traceability

Reliable manufacturers act as long-term partners rather than short-term suppliers.

Medical Instrument Machining Applications

Medical instrument machining covers a wide range of handheld and precision tools used in clinical and surgical environments. These instruments often require smooth surface finishes, tight tolerances, and repeatable quality.

Typical medical instruments include:

Surgical forceps, clamps, and cutting tools

Diagnostic probes and testing devices

Precision housings for medical equipment

Custom tool components for specialized procedures

Precision CNC and Swiss machining are commonly used to ensure consistency across production batches.

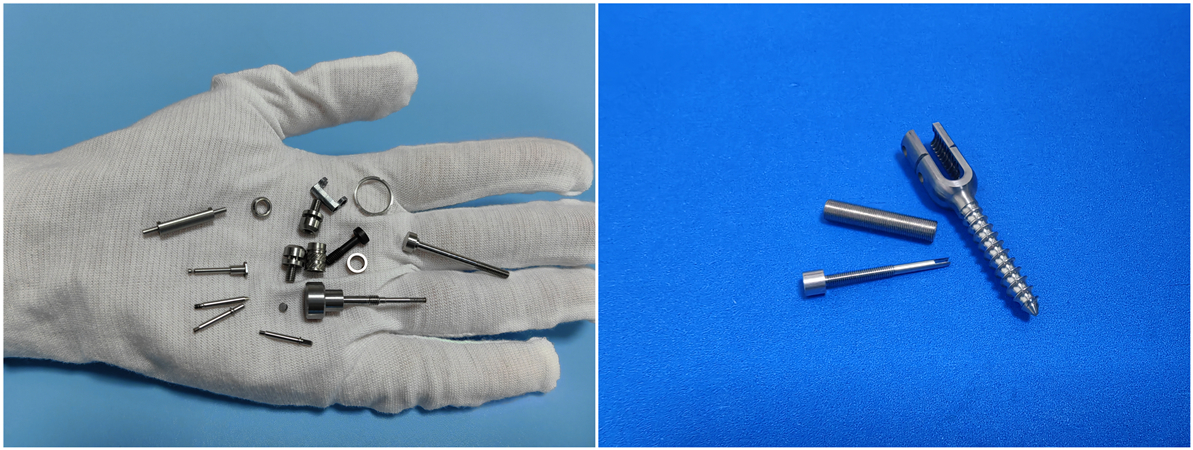

Surgical and Medical Machined Parts

The production of surgical and medical machined parts demands specialized expertise due to the functional and regulatory requirements involved. These parts may be used in direct patient contact or within critical medical systems.

Examples include:

Surgical pins, shafts, and fasteners

Structural components for medical devices

Precision connectors and fittings

Custom machined medical assemblies

Advanced machining processes ensure dimensional accuracy, reliability, and long-term performance in demanding medical environments.

RMS Medical Parts Machining and Specialized Solutions

RMS medical parts machining typically refers to repeatable manufacturing systems designed to maintain consistency across production runs. These systems are especially important for medical components that require stable quality and tight tolerance control over time.

By combining CNC automation, Swiss machining, and inspection processes, manufacturers can achieve reliable output for both low-volume and medium-volume medical programs.

Why Precision Matters in Medical Device Machining

In medical manufacturing, precision is more than a technical requirement—it is a safety requirement. High-quality medical device precision machining reduces risk, improves device performance, and supports regulatory compliance.

Manufacturers that invest in controlled machining systems and experienced engineering teams are better positioned to meet the evolving demands of the medical device industry.

Discover how precision medical machining supports complex medical devices and surgical components.

Conclusion

From medical device CNC machining to medical device contract machining, precision manufacturing plays a vital role in modern healthcare technology. Working with experienced medical device machining manufacturers ensures accuracy, consistency, and confidence throughout the supply chain.

By leveraging specialized medical precision machining capabilities, medical OEMs can bring reliable, high-performance products to market while meeting strict quality and compliance standards.