Swiss machined components important across all industries where high-precision, accuracy, consistency and miniaturization are critical factors of product design. Medical components, aerospace and electronics custom parts, the precise and cost-effective nature of Swiss machining is second to none.

What are Swiss Machined Components?

Swiss machining, or Swiss screw machining is a specialized machining process that is perfect at creating slender, complex parts with tight tolerances. Swiss machining is different than traditional CNC lathes because the Swiss-style CNC machine holds the workpiece close to the cutting tool, reducing deflection and increasing precision.

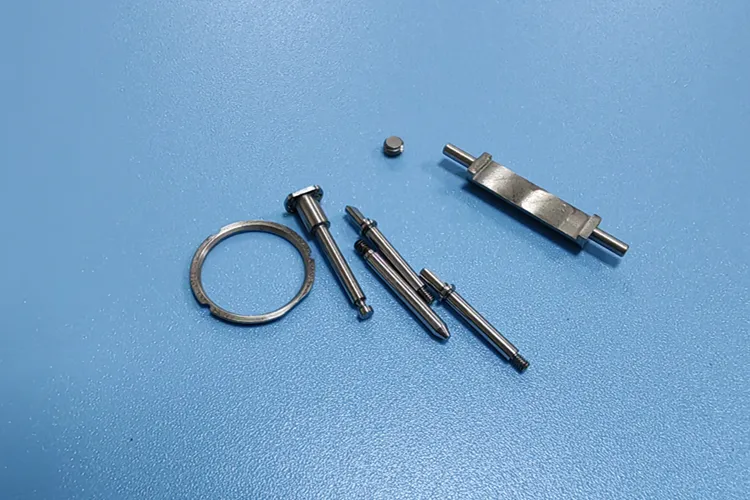

Common examples of Swiss machined components are shafts, connectors, pins, screws, and any other slim, cylindrical part that can be made from metals like stainless steel, brass, aluminum, and titanium.

Core Benefits of Precision Machined Components

Tight Tolerances: Tolerances can be as tight as ±0.001mm. Perfect for mission-critical applications.

High Repeatability: They will be reliably repeated 100 percent of the time for high-volume production.

Multi-Axis Machining: CADCAM programming allows for producing complex geometries in a credible manner in one set-up while reducing cycle times.

Cost-Effective when Long Runs are Required: Reduce waste and labour for post-processes manufacturing.

From custom machined parts for medical devices, to precision machined components for an assembly for a commercial aviation component, Swiss machining will deliver remarkable scalability and quality.

Industries that Make Use of Custom Swiss Machining

Surgical instruments, orthopedic implants, bone screws and dental components require extreme precision and biocompatibility.

Crucial parts to an aircraft engine like fuel connectors, valve components and precision pins are machined to tight tolerances from titanium or aluminum alloys.

Miniature precision is expected of micro connectors, housing, and fittings along with a consistent electrical performance.

Aerospace and defence engine components can include relevant pieces like sensor enclosures, actuators, and shafts are good examples of how Swiss turning can be useful when reliability is important in a harsh environment.

Why Falcon CNC Swiss?

Falcon CNC Swiss manufacture custom parts with tight indexing like Swiss-style machining. With Falcon's multi-axis CNC machining and ISO-standard for quality, Falcon CNC Swiss supports range of prototyping to mass production for their clients globally.

We machine components from:

Stainless Steel

Titanium

Brass

Aluminum

Engineering Plastics

To learn about all of the services offered from Falcon CNC, check out the links below.

Swiss Machining Services

Precision CNC Machining Service

Conclusion

As industries push the limits of performance and miniaturization, the demand for Swiss machined components continuously increases. Partnering with a highly capable Swiss machining company will assure your components will meet the standards of accuracy, durability and cost each time.

Are you searching for a precision machined components supplier or custom machined parts supplier? Call or send Falcon CNC Swiss today to discuss your required machining solution.