The medical device industry operates on a razor's edge. There is zero tolerance for error. A microscopic imperfection, a deviation of a few microns, or a material inconsistency can be the difference between a life-saving innovation and a catastrophic failure. For engineers and product developers tasked with creating the next generation of medical technology, selecting the right manufacturing partner is one of the most critical decisions they will make.

In this landscape, not all machining processes are created equal. While standard CNC machining has its place, the complex, miniature, and high-tolerance nature of most modern medical devices demands a more specialized approach. This is where Swiss machining emerges as the gold standard.

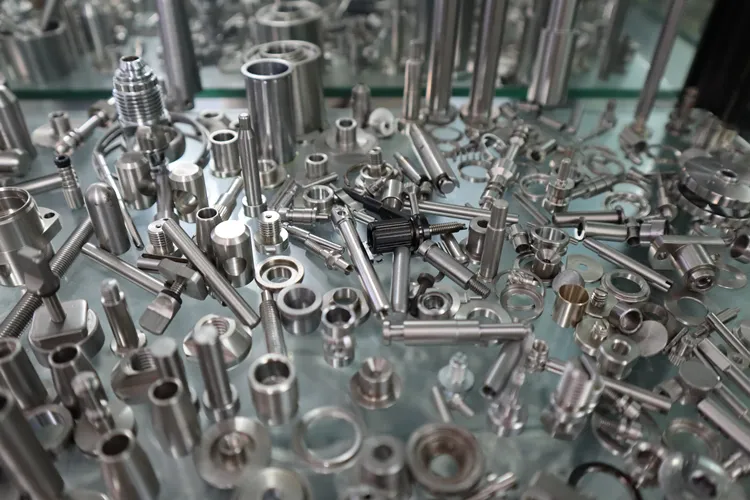

As a leading medical machining company, Falcon CNC Swiss specializes in leveraging the unique advantages of Swiss-type lathes to produce components that meet the stringent demands of the healthcare sector. In this deep-dive, we will explore the key benefits of Swiss machining for medical devices from an engineering perspective, explaining not just the "what," but the crucial "why" behind its superiority for your most challenging projects.

Understanding the Core Technology: What is Swiss Machining?

Before we delve into the medical-specific benefits, it's essential to understand the fundamental mechanism that sets Swiss-type lathes apart. Unlike conventional lathes where the workpiece is fixed and the tool moves, a Swiss screw machine incorporates a guiding bushing. The bar stock is fed through this bushing, and the tools operate on the material directly adjacent to this support point.

Why does this matter for precision?

The guiding bushing provides immense support to the raw material, drastically reducing deflection and vibration during the cutting process. This is the foundational principle that enables the unparalleled precision and ability to machine long, slender, and complex parts that would be impossible or highly inefficient on a standard CNC lathe. Our expertise in this specific technology is what makes us a top-tier precision medical machining service.

Key Benefit #1: Unmatched Precision for Miniaturized & Complex Geometries

The trend in medical technology is unequivocally towards minimally invasive surgery (MIS). This requires instruments and implants that are incredibly small, yet incredibly complex. Think of arthroscopic shavers, endoscopic components, or miniature bone screws.

Tight Tolerances: Precision CNC medical machining on Swiss-type lathes routinely holds tolerances within ±0.0002 inches (±0.005mm). This level of repeatability is non-negotiable for components like delivery system tips for catheters or internal mechanisms for insulin pumps, where a few microns can affect performance and safety.

Complex Features in a Single Setup: Swiss machines are equipped with live tooling and secondary spindles, allowing for milling, drilling, cross-hole drilling, and tapping operations to be completed in a single, automated cycle. This "done-in-one" philosophy is a cornerstone of our production medical machining capabilities. It eliminates the errors introduced by multiple fixture setups, ensuring feature-to-feature alignment that is perfect every time.

For Engineers: This single-setup advantage directly translates to improved Geometric Dimensioning and Tolerancing (GD&T) outcomes, particularly for positional tolerances and concentricity. It also significantly reduces production lead times.

Key Benefit #2: Superior Surface Finishes, Reducing Post-Processing

The surface finish of a medical component is not merely an aesthetic concern. A rough surface can harbor bacteria, create friction during insertion, or lead to particulate shedding within the body. Achieving a superior finish directly from the machine is a massive advantage.

The Swiss machining process, with its inherent stability from the guide bushing, allows for higher surface speeds and finer feeds. This results in exceptional surface finishes, often achieving 8 Ra micro-inches or better directly off the machine. For many medical machining components, this eliminates or drastically reduces the need for secondary finishing operations like polishing, which can alter critical dimensions and add cost and time.

Key Benefit #3: Mastering Biocompatible & Challenging Materials

Medical devices are fabricated from a specialized palette of materials chosen for their strength, corrosion resistance, and biocompatibility. However, many of these materials are notoriously difficult to machine.

Common Materials We Excel With:

Titanium (Ti-6Al-4V): The benchmark for implantable devices. It's strong and biocompatible but has low thermal conductivity, making it prone to work hardening and tool wear.

Stainless Steels (e.g., 316L, 17-4PH): Excellent for surgical instruments. They can be gummy and require sharp tooling and precise parameters.

Cobalt-Chromium Alloys (e.g., CoCrMo): Extremely hard and wear-resistant, used for joint replacements. They are abrasive and generate high cutting forces.

PEEK & Other Medical Plastics: Used for trauma spacers and other non-metallic implants. They require sharp tooling to prevent melting and delamination.

Our role as medical machining specialists is to possess the deep material science knowledge and machining parameter database to handle these exotics efficiently. We understand the specific chip loads, coolant types, and tool geometries required to machine these materials successfully without compromising their metallurgical or structural integrity.

Key Benefit #4: Ensuring Regulatory Compliance & Traceability

This is where the conversation moves from pure engineering to the absolute non-negotiables of the medical industry. Medical machining compliance is a system, not just a step in the process.

ISO 13485:2016 Certification: This is the quality management system standard specific to medical devices. A precision medical machining manufacturer certified to this standard has a fully documented system for design control, risk management, production validation, and corrective action. It is a testament to a culture of quality.

Full Material Traceability: Every bar of material used for a medical component must be traceable from receipt to the finished part. This includes maintaining all mill certifications and providing full lot traceability on our certifications of conformity.

Documentation & Validation: We provide comprehensive documentation packages, including First Article Inspection Reports (FAIR), Certificates of Conformity (C of C), and full Device History Records (DHR) for production runs. Our processes are validated to ensure they consistently produce parts meeting specified requirements.

When you partner with Falcon CNC Swiss, you are not just buying a part; you are investing in a compliant, auditable, and reliable supply chain. This makes us a trusted partner among precision medical machining suppliers.

Key Benefit #5: Production Scalability and Cost-Effectiveness

While Swiss machining is renowned for prototyping, its true power is realized in high-volume production. The automation capabilities of modern Swiss-type lathes make them ideal for production medical machining.

High Uptime: With bar feeders, parts can run for hours unattended.

Consistency: The process, once validated, produces part after identical part with minimal variation.

Reduced Total Cost: While the initial part cost might be higher than a simpler process, the "done-in-one" nature, reduced scrap rates, and eliminated secondary operations often lead to a lower total cost of ownership, especially when factoring in quality and compliance risks

Case Study: A Complex Orthopedic Component

To illustrate these benefits in action, consider a recent project: a miniature, cannulated (hollow) bone screw made from Ti-6Al-4V. The part required

A deep, precise internal diameter (cannulation).

A complex, self-tapping thread form.

A cruciform drive socket on the head.

A highly polished, implant-grade surface finish.

A conventional CNC approach would have required at least three different setups and multiple machines, increasing the risk of misalignment and handling damage. Using our multi-axis Swiss machining services, we produced the complete part in a single setup. The guide bushing ensured the slender, cannulated stock did not deflect during drilling. The live tooling perfectly machined the drive socket and thread form. The result was a flawless component that met all dimensional and surface finish requirements, passed all validation, and was delivered at a scalable production cost.

Conclusion: Why Your Next Medical Device Project Belongs with a Swiss Machining Expert

The margin for error in medical device manufacturing is zero. The choice of your manufacturing process and partner is a strategic decision that impacts product efficacy, patient safety, and time-to-market.

Swiss machining offers a unique combination of extreme precision, complex geometry capability, superior surface finishes, and mastery over difficult materials—all within a framework built for compliance and scalable production.

As you evaluate precision medical machining services for your components, look for a partner that demonstrates not just technical capability, but a deep understanding of the medical industry's rigorous standards.

At Falcon CNC Swiss, we bridge the gap between advanced engineering and medical machining compliance. We invite you to leverage our expertise as medical machining specialists to bring your most innovative and demanding medical device concepts to life.

Ready to discuss your project's specific requirements?

Explore our comprehensive capabilities and let our engineering team provide a solution tailored to your needs.

Explore Our Swiss Machining Services →