Introduction: The Precision Imperative in Swiss Machining

In the high-stakes world of precision manufacturing, the term "tolerance" is not merely a specification—it is a covenant of performance, reliability, and interchangeability. For engineers and procurement specialists sourcing CNC Swiss machined parts, understanding tolerances is paramount to project success. This guide, crafted from decades of hands-on engineering and machining experience at Falcon CNC Swiss, will demystify the complex relationship between part design, material selection, and the unparalleled capabilities of Swiss machining services to hold extreme tolerances consistently.

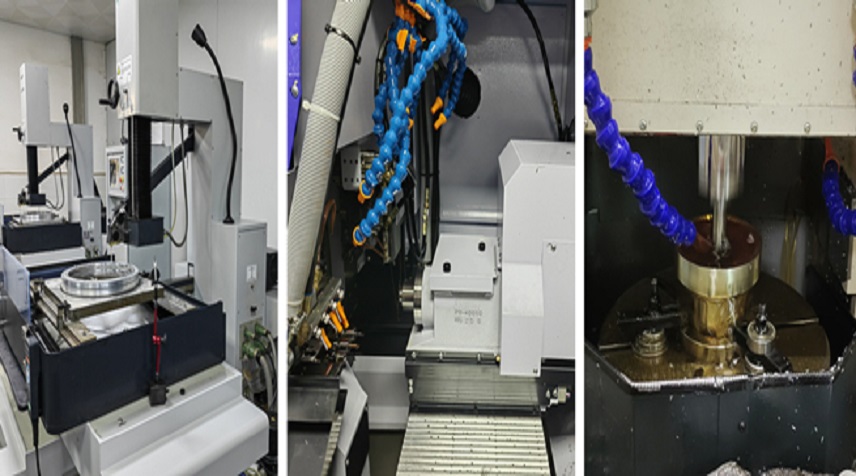

Unlike conventional machining, the Swiss screw machine (or CNC Swiss lathe) provides exceptional stability for machining small diameter Swiss machined parts with complex features and stringent tolerance requirements over long production runs. Whether you are working with medical implants, aerospace actuators, or intricate electronic connectors, this guide will serve as your authoritative resource.

Chapter 1: Decoding Tolerance – More Than Just a Number

What is a Dimensional Tolerance?

In engineering drawings, a tolerance defines the permissible limit or limits of variation in a physical dimension. It is the bridge between ideal design and manufacturable reality. A callout of Ø 0.125" ±0.0005" on a shaft diameter for Swiss machined components means the finished part must measure between 0.1245" and 0.1255". Any part within this range is acceptable; any part outside is scrap.

Why Tolerances are Critical for Swiss Machined Parts

Functional Fit: Ensures parts assemble and interact correctly—think of a pin sliding smoothly into a bushings without undue play or binding.

Performance: Directly impacts pressure integrity in fluid systems, electrical conductivity in connectors, and motion precision in assemblies.

Cost Efficiency: Unnecessarily tight tolerances (±0.0001") can exponentially increase machining time, inspection costs, and scrap rates. The golden rule: specify the widest tolerance that still guarantees part function.

Chapter 2: Material Science & Tolerances – An Inseparable Bond

The choice of material is the first and perhaps most critical decision influencing achievable tolerances. Different swiss machined parts materials behave uniquely under the cutting forces, temperatures, and stresses of machining.

Standard Materials and Their Machinability

Aluminum (e.g., 6061, 7075): Excellent machinability. Stable, predictable, and allows for very tight tolerances and high surface finishes. Ideal for complex CNC Swiss machined components.

Stainless Steels (e.g., 303, 304, 316): Tougher and work-hardening. Require rigid setups and sharp tooling. Tolerances are achievable but may involve slower speeds and specialized tool geometries.

Brass & Copper Alloys: Free-machining. Often permit the tightest tolerances and fastest cycle times due to their soft, consistent structure.

Challenging Alloys: The High-Performance Frontier

Titanium Swiss Machined Parts (e.g., Grade 2, 5 Ti-6Al-4V): Titanium’s poor thermal conductivity and galling tendency make it a challenge. Heat concentrates at the cutting edge, leading to rapid tool wear and potential part distortion. Holding tight tolerances requires:

High-pressure coolant directed precisely at the cut.

Reduced cutting speeds and feeds.

Exceptional machine rigidity (a hallmark of Swiss lathes).

High Temperature Alloy Swiss Machined Parts (e.g., Inconel 718, Hastelloy X): These superalloys are the ultimate test. Their strength at elevated temperatures causes extreme tool pressure and wear. Tolerance strategies include:

Aggressive, constant coolant flow to control work-piece temperature.

Ceramic or specialized carbide tooling.

Multi-stage machining with stress-relief steps to prevent distortion from internal stresses.

Expert Insight: At Falcon CNC Swiss, we routinely machine these exotic materials. Our Swiss machining services are calibrated for these challenges, employing live tooling and subspindle capabilities to complete parts in one setup, which is crucial for maintaining concentricity and positional tolerances in tough materials.

Chapter 3: The Swiss Machining Advantage for Holding Tight Tolerances

Why is the Swiss lathe uniquely suited for precision small diameter Swiss machined parts?

Guide Bushing Support: The material bar is supported mere millimeters from the cutting action by a guide bushing. This eliminates deflection, the arch-nemesis of tolerance in long, slender parts.

Single-Setup Production: Complex CNC Swiss machined parts with milling, drilling, and cross-holes can be completed in one clamping. This eliminates cumulative errors from multiple setups, directly preserving critical geometric tolerances like true position and concentricity.

Thermal Stability: Modern CNC Swiss machines are built with thermally symmetric frames and often feature coolant temperature control, minimizing thermal growth that can subtly shift dimensions over a production run.

Chapter 4: A Practical Guide to Specifying Tolerances on Your Drawings

Geometric Dimensioning and Tolerancing (GD&T) vs. Linear Tolerances

For Swiss machined components with complex functional relationships, GD&T is superior. Instead of just controlling a diameter, you can control:

Cylindricity: How perfectly cylindrical a shaft is.

True Position: The exact location of a hole relative to a datum axis.

Parallelism/Perpendicularity: Of features to a datum.

A simple linear tolerance on a hole location may be ±0.002". A True Position tolerance of Ø0.005" with a proper datum structure often provides a larger, more functional "tolerance zone" while better ensuring assembly.

General Tolerance Guidelines for Swiss Machining

Standard Machining Tolerance: A drawing note stating "Tolerances per ISO 2768-m" or "±0.005" unless otherwise specified" is common and cost-effective for non-critical features.

Fine Precision Tolerances: For critical features on Swiss machined parts, ±0.0005" is routinely achievable. Under optimal conditions (right material, part geometry, and tooling), ±0.0002" is possible.

Micro-Machining Tolerances: For parts under 1mm in diameter, tolerances are often discussed in microns (µm). Here, the stability of the Swiss lathe is indispensable.

Chapter 5: Industry Applications – Where Tolerance is Non-Negotiable

Medical & Surgical Devices: Titanium Swiss machined parts for bone screws and surgical instruments require biocompatibility and flawless fit. Tolerances affect osseointegration and surgical efficacy.

Aerospace & Defense: High temperature alloy swiss machined parts in fuel systems and sensors must perform under extreme conditions. A variance of a few ten-thousandths of an inch can impact airflow, sealing, and safety.

Electronics & Connectors: Miniature CNC Swiss machined components for RF connectors or pins demand perfect concentricity and diameter control to ensure signal integrity and low insertion force.

Chapter 6: Partnering for Success – From Design to Delivery

Achieving perfect tolerances is a partnership. Here’s how to set your project up for success:

Design for Manufacturability (DFM): Engage with your machining partner early. A slight increase in a corner radius or a modification to a blind hole depth can make a part dramatically easier and more cost-effective to machine to spec. We provide comprehensive DFM analysis as part of our Swiss machining services.

Communication is Key: Provide complete drawings with clearly identified critical tolerances. Explain the part's function. What does this surface interact with? Is this a sealing surface or a clearance fit?

Trust the Process: A reputable partner like Falcon CNC Swiss will have a robust Quality Management System (QMS) involving in-process inspection, Statistical Process Control (SPC), and final validation with CMMs (Coordinate Measuring Machines) to ensure every batch of Swiss machined parts meets your print.

Conclusion: Precision as a Promise

In precision machining, tolerances are the language of trust. Specifying, understanding, and achieving them requires a blend of engineering knowledge, material science, and mastery of advanced manufacturing technology like CNC Swiss machining.

For your next project requiring impeccable precision in titanium Swiss machined parts, high-temperature alloy swiss machined parts, or intricate small diameter Swiss machined parts, we invite you to leverage our expertise. Explore our comprehensive capabilities and let’s discuss how we can bring your most demanding designs to life with unwavering accuracy.

Ready to see what true precision can do for your project? Discover our full range of high-tolerance Swiss Machining Services.