As product designs get smaller and performance requirements ramp up, manufacturers in medical, electronics, and high-tech continue to invest in micro CNC machining. Producing extremely small, extremely high-precision components is now no longer optional—it’s a matter of competitive need.

At Falcon CNC Swiss, we perform precision CNC micro machining, powered by sophisticated Swiss machining technology, delivering ongoing accuracy, repeatability and scalability necessary for micro-sized parts with complex specifications.

What Is Micro CNC Machining?

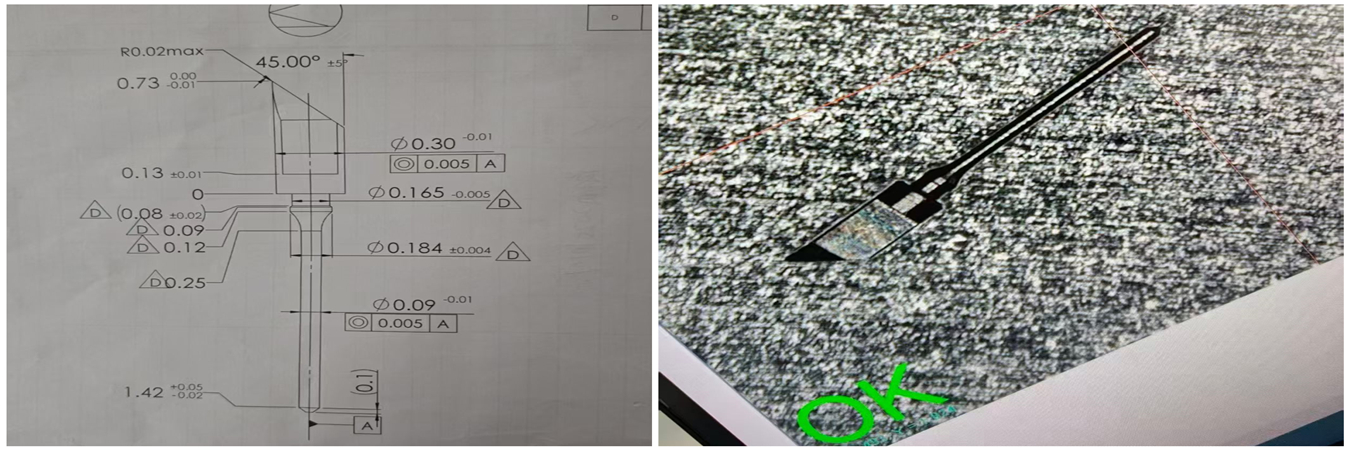

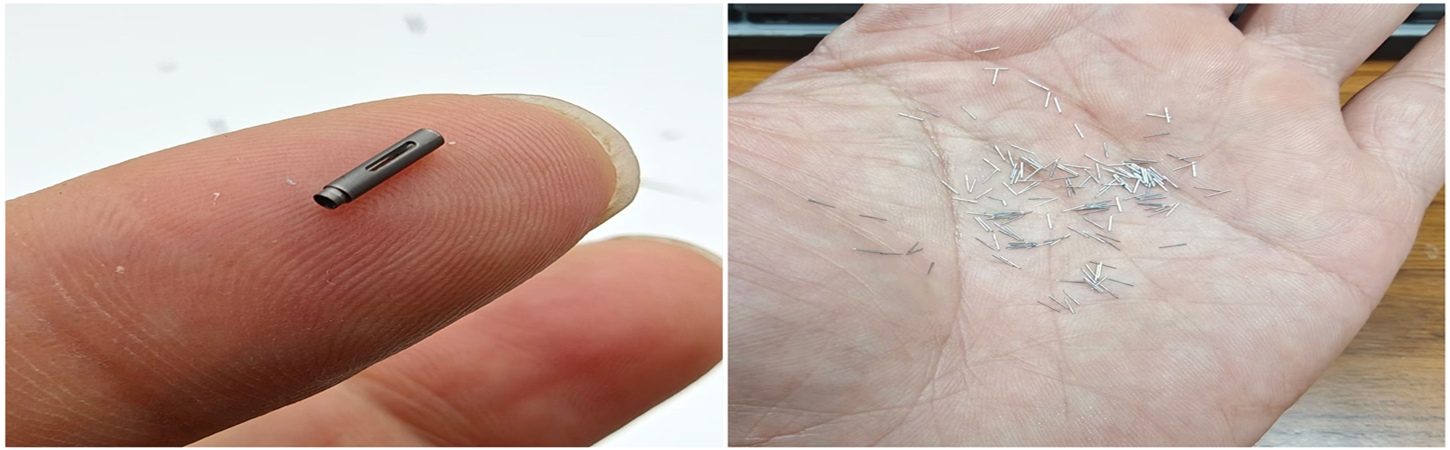

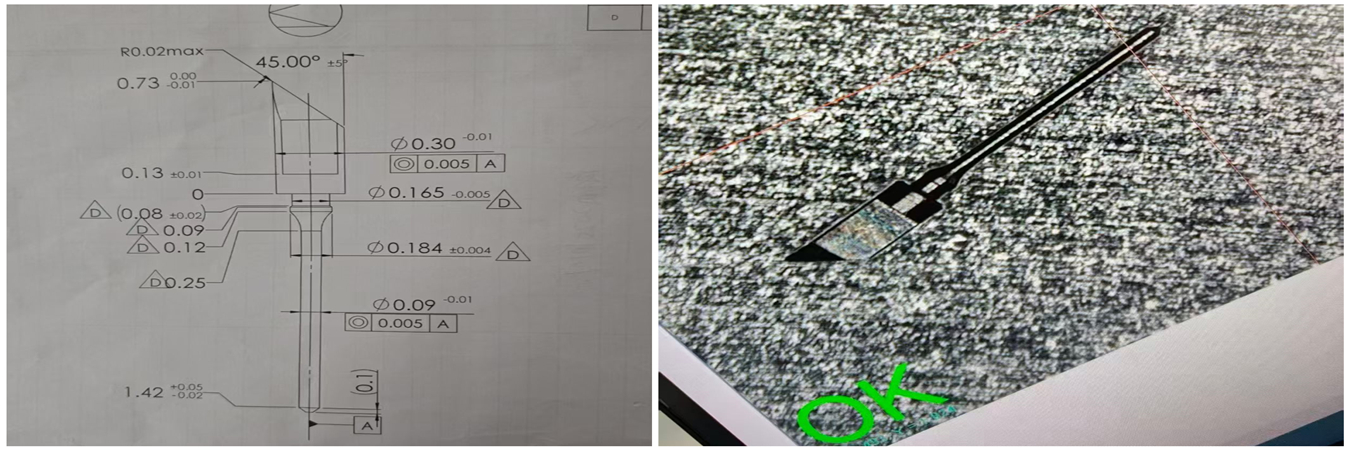

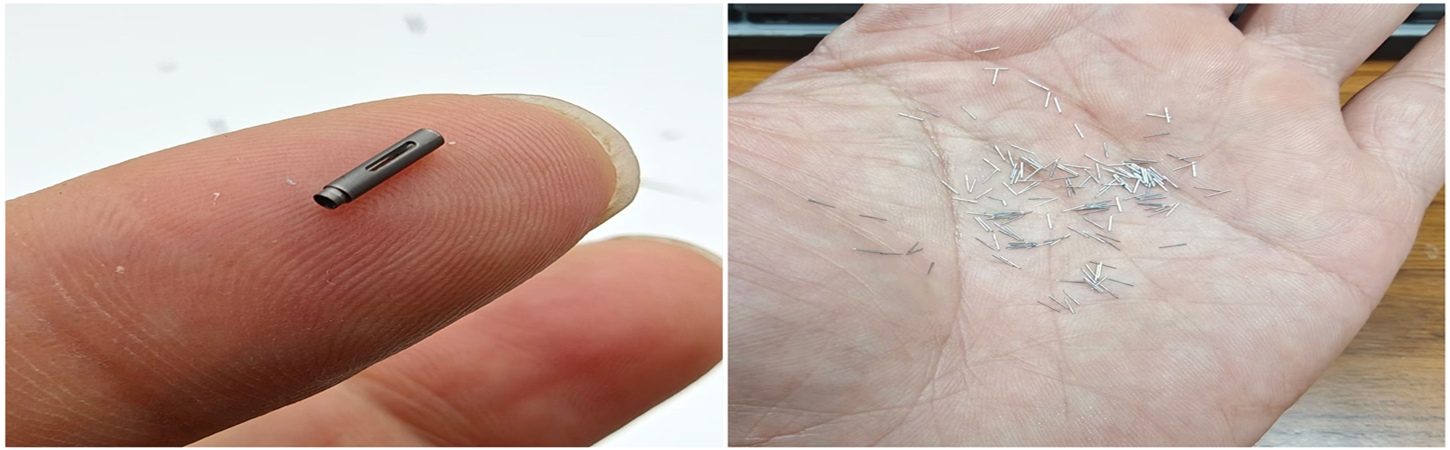

Micro CNC machining is a process of fabricating extremely small components—usually measured in millions of a meter or millimeters in diameter—that require:

Micro machining is different from standard CNC machining, requiring specialized equipment, tooling, and process control. Swiss micro machining, using Swiss lathes, is ideally suited to this need.

Why Swiss Machining Is Optimal for Micro Precision Machining

Swiss micro machining originated in the application of watch-making—fitting quite well the need for micro-scale manufacturing. Today, it continues to be the best method for high-precision, small diameter components.

Benefits of Swiss micro machining include:

Guide bushing support for added stability

Minimized vibration

Excellent centrism and repeatability

Ability to micro machine long slender components

Complete machining in a single setup

These benefits mean that a professional micro machining company has the assets to produce small complex parts that standard CNC lathes are not quite able to achieve consistently.

You will find Swiss technology is at the heart of our Swiss Machining Services at Falcon CNC Swiss.

Our Micro Machining Services

As a complete prototype-to-production micro machining service provider, we do the whole package. Our capabilities include:

Micro turning and micro milling

Contouring of complex parts

Secondary operations and finishing

Tight tolerance inspection and other quality control

From rapid prototyping to high volume production, our team produces custom micro machining solutions to your exacting specifications.

Custom Micro Machining for Critical Applications

Custom micro machining is especially critical where standards are exacting as failure is not an option. Falcon CNC Swiss provides services to:

Medical devices and surgical use components

Electronics connectors and sensor housings

Optical and instrumentation parts

Aerospace and automation systems

Medicine in particular calls for strict quality, traceability of materials, and repeatability—all areas where Swiss machining excels beyond other options.

China Micro Machining Services with No Compromise

Falcon CNC is a trusted provider of China micro machining services and backed by sophisticated Swiss machining technology.

Our processes give our clients the benefit of:

This combination of technologies and assets is the only way we can support our customers worldwide as their reliable micro machine shop and long-term manufacturing partner.

Choosing Your Micro Machining Company

An integral decision for the success of your project is selecting the proper micro machining company for your use. Key targets to look for include:

Proven Swiss micro machining capability

History with micro-sized tolerances

Advanced QC systems and inspection processes

Engineering support and process explorations

We’re pleased at Falcon CNC Swiss to be all those points and more!

From Prototype to Production

Whether you’re a startup searching for early prototypes or an established OEM that’s ramping up production, Falcon CNC Swiss’ micro machining services are designed to grow with you.

By utilizing Swiss machining we shorten cycle times, reduce scrap, and make consistent parts, so that you know you’re getting measurable value throughout the lifecycle of the product.

Partner with Falcon CNC Swiss

If a project requires high-precision, micro components, Swiss machining is the way to go.

Learn more about how Falcon CNC Swiss’ Swiss technology comes to the aid of demanding micro scale applications by checking out our Swiss Machining Services page.