As technology advances, the need for micro machined components has never been greater. Everything from medical devices, electronics,and aerospace requires parts that are extremely tiny in size. Meeting these requirements calls for specialized equipment, skilled engineering, and specific techniques. At Falcon CNC Swiss our Swiss machining services offer unparalleled precision for you micro machined needs.

Understanding Micro Machining and Fabrication

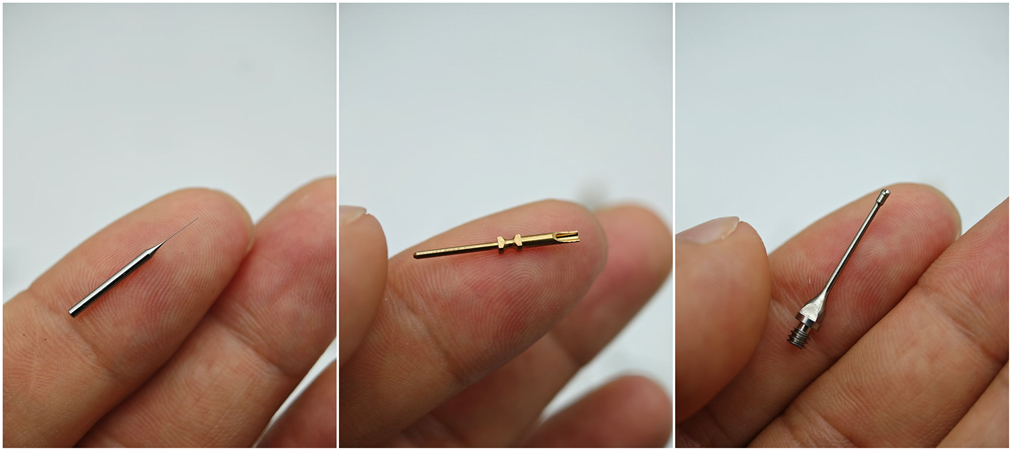

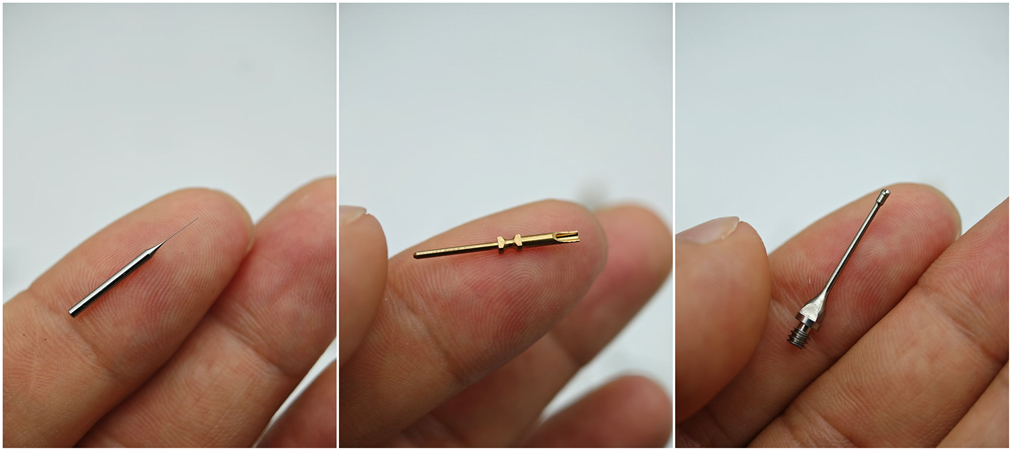

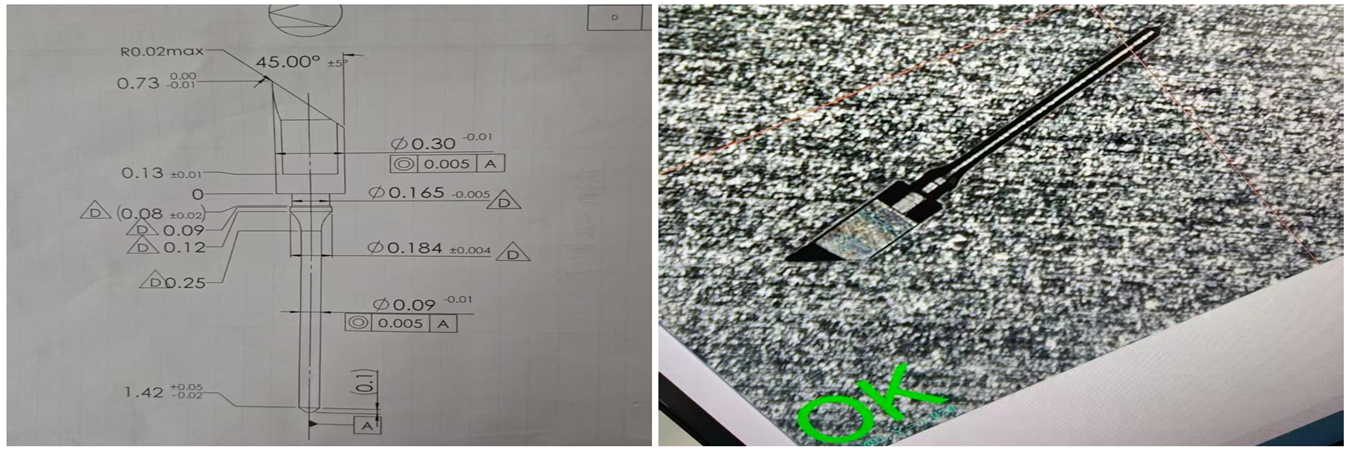

Micro machining and fabricating means making especially tiny components. Whether CNC micro machining parts for sensors or micro machined parts for surgical instruments, getting thing just right is key. These micro sized features ideally require:

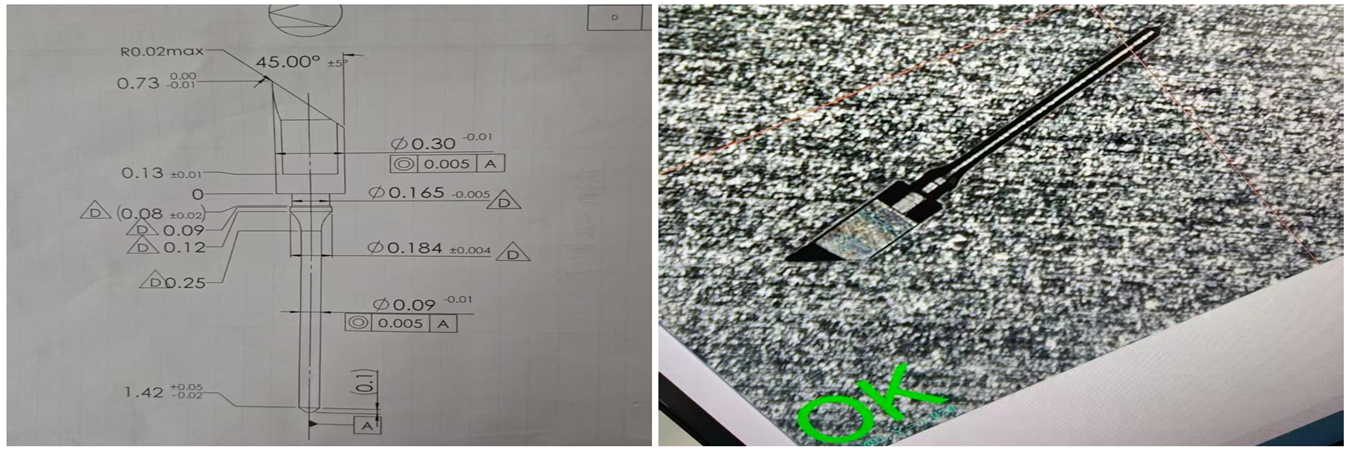

Tight tolerances of microns

High-quality surface finishes

Dimensional consistency

Capability of operating in complex geometries.

Blending conventional precision methods with Swiss micro machining and micro parts can often be accomplished much more efficiently than is possible with conventional machining. Check more about our Swiss machining capabilities now.

The job of a micro machine shop

With important jobs, hiring the right micro machine shop is vital. An experienced shop knows how to work with micro sized materials, apply the right tooling, and use proper cutting speeds. Falcon CNC Swiss is the premier micro precision machining Ltd specializing in custom micro machining, prototype development, small and large batch production lots, quality control and inspection. Professional micro machine shop uses are less wasteful and more reliable since the micro machined component is sure to meet desired functional and cosmetic requirements.

CNC Micro Machining for Micro Components

CNC micro machining parts calls for similar skills in programming, and small cutting tools. Falcon CNC Swiss does the work and specializes in both CNC machining parts and super elaborate machining micro turningume parts including:

Automated high-precision cutting

Complex part geometries done in a single setup

Repeatable, tight tolerance production lots

Integration with secondary finishing operations as required.

Our engineers can work with tough designs and still keep optimal cycle times. This service allows our clients to move from prototyping to production smoothly.

Uses for Micro Machined Parts

Micro machined parts are widely used throughout in industries. Most all of the following applications require ultra fine tolerances and extreme accuracy.

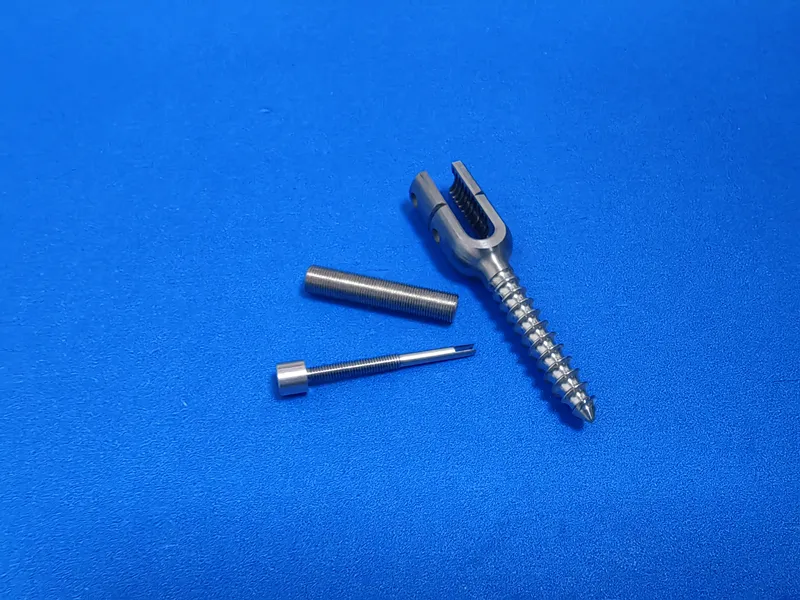

Medical micro machining: surgical tools, implants, diagnostic devices. In these components the tolerances are extreme and safety is vital.

Electronics: connectors, sensors and micro-actuators.

Aerospace: precision fasteners, instrument components and others.

Automotive: micro shafts, pins and small assemblies.

Fine tolerances and repeatability are critical for each of those applications.

Benefits of Swiss Machining for Micro Precision

Why is swiss machining micro turning parts, unlike turning or other methods, representative of the way an object must be if it is to be rotated? From components ready to ship to our customer, high volume Swiss machining means:

Continuous support of the workpiece via guide bushings

Less vibration to produce ultra fine tolerances

Exceptional concentricity and surface finish to dimensions

Ability to machine long, slender micro parts

Length of part diameters can be similar in size to width, that is, 0.7 to 1.0 mm/0.05 mm to 0.4 mm length. With a Swiss type machine much of a micro part can be cut to the finished size and shape in a single setup. This reduces talk time and increases the dimensional stability across large production runs.

Custom Micro Machining Services

Falcon CNC Swiss offers custom micro machining solutions, shaping each CNC micro machining parts to specification.

Our micro machined components include medical micro machining with traceability, stringent quality control and more.

Micro Machining Services We offer:

Design consultation

Micro turning, milling, multi-axis

Surface finishing, coating, secondary

Inspection, tolerance and more

“Full-spectrum” micro processing to ensure more parts arrive per spec regardless of complexity

Coosing the Right Micro Machining Company for Your Project

Choosing the right micro machining company affects the project outcome, late or early and expense. Falcon CNC Swiss has capable machinists and engineering departments and drawing and technology, providing global quality standards to customers on the other side of the planet.

We offer:

Swiss machining capabilities

Quick, on-demand prototype machining

Production for micro components

Compliant to international quality

Conclusion

Regardless of micro CNC machining parts or machining micro turning parts, it’s clearly critical that everything be perfect. In-house technologies and discretion is key. The Falcon CNC Swiss bringing contemporary Swiss machining and knowledge to the fore with reliable micro machining and fabrication.

If you have a project for us, please see our Swiss Machining Services.