In the world of engineering and design, a bracket is an often-oversimplified mechanical component. However, it plays a vital role, needing to hold, support, and align crucial components of an assembly, generally while experiencing significant mechanical loads, vibration, and environmental conditions. The quality of the design and manufacturing of the bracket is crucial, as the integrity, reliability, and lifetime of the entire assembly hangs on it. This gives rise to an important question: What are the methods of manufacturing brackets?

The choice of the means of manufacture is not something that can be answered in a one-size-fits-all method. It depends largely on material, complexity, volumes, budget, and precision required. In this article, we will discuss the most common methods of manufacture for brackets, with particular attention paid to CNC machining for brackets, the process which defines the gold standard in terms of versatility and precision, and a core competency here at Falcon CNC Swiss.

Understanding the Bracket Manufacturing Environment

There are several ways in which raw materials can be manufacturally converted into functional brackets. They tend to fall into three areas: subtractive, formative, and additive.

Subtractive methods of manufacture: Material is removed from a solid block of material to leave the part complete. (CNC Machining)

Formative methods of manufacture: Material is formed into its required shape using forces, heat, or dies. (Metal fabrication, die-casting.)

Additive methods of manufacture: Material is built up bit by bit, until the part is formed. (3D Printing.)

We shall examine each method in turn.

Method 1 - Metal Fabrication.

This technique is by far the most prevalent method of bracket manufacture in high volumes, particularly on brackets for consumer electronics units, enclosures, and automotive applications.

- Laser Cutting:- Use a high-power laser to cut complex and detailed 2D shapes out of sheet metal.

- Punching/Stamping:- A die may be employed to punch holes and/or shapes out of the sheet metal.

- Bending:- A metal press brake is used to fold the sheet of metal which has been cut into its two-dimensional shape into the final 3D configuration.

Advantages:- This process is the cheapest method of producing brackets in high volumes, the tooling once manufactured leads to high speed of production rates, the strength-to-weight-ratio can be excellent for thin walls.

Disadvantages:- The wall thickness is limited to a uniform thickness, geometric complexity is limited to shapes capable of being processed by bending, welding, etc. can be needed for assembly, which can cause stresses in the component.

Method 2: Casting

Casting is the forming of a cavity of the desired shape into which molten metal is poured.

Process: The common methods of casting are Die Casting (for non-ferrous metals such as aluminum and zinc) and Investment Casting (for more complex geometries in Steel and Titanium).

Pros: Good for getting most complex solid geometries which are difficult to machine, high production rates for die cast, almost no waste of material.

Cons: Not as high a strength and surface finish as machining, porosity may be a problem, cost of the necessary equipment (molds) is excessive, lower in accuracy of dimension requiring usually second machining for critical features.

Method Type 3: 3D Printing (Additive Manufacturing)

While this is revolutionary for prototyping and for very complex, low volume parts, it is not so useful for structural brackets.

Process: METAL 3D printing (DMLS, SLM) is used to build brackets of layered metal powder.

Pros: Unprecedented freedom of design, may be employed to build in internal channels liver as well as organic shapes impossible with any other possible method, no equipment cost is to be regarded, excellent for rapid prototyping.

Cons: Generally less mechanical strength and fatigue than wrought and machined parts. Too, higher price per piece, slower building rates, usually surface finishing required.

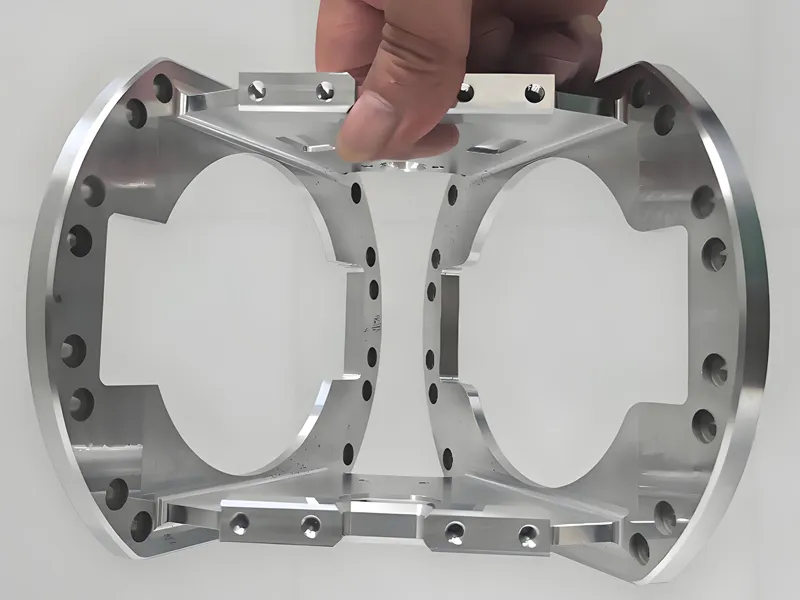

Method Type 4: CNC Machining - The Gold Standard of Precision

Now, let us get into a detailed description of the method which is the specialty of Falcon CNC Swiss - Computer Numerical Control (CNC) Machining, a subtractive process whereby programmed software on a computer is used to move the factory tools and machinery.

Why CNC Machining is the Better Method for Brackets for High Duty.

While all of these methods have their places, when the employment of the highest attainable levels of precision, strength and reliability is desired, precision CNC bracket machining is the process used.

The CNC Machining Process for Brackets:

Design and Programming: A three dimensional model (CAD) is made and then turned into instructions for the use of the machining (CAM) on the CNC machine.

Material: A solid block of material (billet) is selected from aluminum, stainless steel, titanium, or engineering plastics.

Machining: The CNC machine (a mill, lathe or Swiss type lathe) employs a variety of cutting tools to satisfactorily remove the material, closely following the digital form with which they are programmed.

Finishing: The parts are deburred, and a secondary treatment of surface may be given, as anodizing, plating, and painting.

Best Features Square by CNC Machined Brackets:

Strength and Integrity of Material: The CNC parts are made from a solid piece of wrought material, as distinguished from casting or 3D printing (homogeneous grain structure, etc.), which eliminates the danger of porosity, providing necessarily, more strength, longer durability, fatigue resistance, etc.

Exceptional Flexibility of Design: CNC machinery has the possibility of infinite complexity of geometry, with high complexity of features. Also deep threads and acute angles may be produced with ease which are difficult or impossible to secure by either fabrication or casting. It enables the engineer to design for the best function necessary, instead of for manufacturability.Also, there is a very good surface finish obtainable. The parts come from the machine with an extremely good finish, eliminating nearly all secondary surface finish.

Fast Prototyping and Production: While tooling is not required, modern CNC setups allow speedy passage from concept to finished part, making them suitable both for one-off prototypes and medium-to-high quantity production runs.

CNC Machining vs. Other Methods: A Quick Comparison

| Feature | CNC Machining | Sheet Metal | Casting |

|---|

| Precision | Excellent | Good | Fair |

| Strength | Excellent | Good | Fair to Good |

| Complexity | High | Limited | High |

| Lead Time | Fast (no tooling) | Medium (tooling req.) | Slow (tooling req.) |

| Cost (Low Vol.) | Competitive | High | High |

| Cost (High Vol.) | Medium | Low | Low |

| Material Options | Very Wide | Wide | Limited |

Conclusion: Making the Right Choice Cassette Back-Bracket Manufacturing Method

So, which is the best method to manufacture your mounting brackets?

For simple high production volume parts where cost is the major factor, sheet metal fabricated parts are hard to beat.

For highly complex solid shapes in high volume where precision is not so critically important, casting feature sets may be the answer.

For prototyping and one-off parts especially with “impossible” geometries, 3D printing is invaluable.

However, when your application cannot compromise by lower standards in precision, strength, reliability and quality of materials, CNC machining is preeminently the choice. This method provides parts built to last and perform in the must demanding environments.

At Falcon CNC Swiss, we specialize in the art and science of precision CNC bracket machining. Our advanced Swiss-type lathes and multi-axis milling centers and highly trained personnel have the capability to provide you with your custom, complex brackets produced with the highest degree of accuracy and repeatability. We know and understand that, more than just a component, a bracket is the foundation of your product’s success.

Are you ready to see what the Falcon CNC Swiss difference is? If you have a design for a critical mounting bracket, let us provide you with a quote. Contact us today or see our capabilities page to learn how we can bring your most challenging bracket designs to life.