If you often work with hydraulic systems, a component you don't always think about but should appreciate is the hydraulic manifold. The hydraulic manifold is the centralized "hub" of the hydraulic systems, nowhere better displaying the importance of precisely routing the hydraulic fluid to and from pumps, valves, cylinders, etc. A well-manufactured manifold will ensure that the system performs at peak efficiency, will minimize pressure loss, and will minimize or totally eliminate leaks. So we know what it is and what it can do, but how is a hydraulic manifold block actually manufactured?

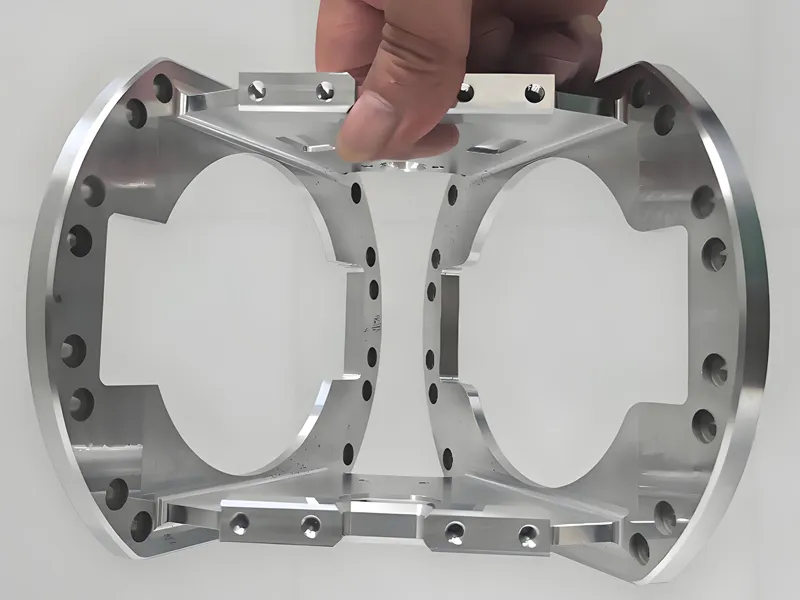

The manufacturing process is precision machining. The idea seems simple, but the process of taking a raw block of material and turning it into a complicated block with various passages so that they are leak proof is a job that takes training, skill, high-tech machinery and serious quality control. In the following paragraphs we will take you step by step through the important phases of the manufacture of hydraulic manifolds and explain to you why the "how" is as important and perhaps more so than the "what."

1.) Design and Engineering - It Is The Blueprint For Success

Before any metal is cut, the manifold must first be thoroughly designed. This is done with the aid of an advanced 3 D software called CAD (computer aided design), whereby a digital design of the block is made. The digital design will cover:

(a.) Port locations and sizes - Valves, pumps and actuating devices are located at positions that provide the needed access.

(b.) Internal cross drilling - All of the interconnecting passages. One of the most difficult aspects of this is where two drilling paths in the inside of the block actually intersect the drill paths, this gives rise to the term "cross bores."

(c.) The locations of plugs and fittings - The plugs and fittings are installed for sealing off passages that are not used, and for the purpose of connecting hydraulic lines or hoses.

(d.) Material selection - The selection of the correct material for the proper strength, corrosion resistance, and "hydraulic compatibility" is also important, as has already been stated. The material must be capable of withstanding corrosion and the more severe effects of hydraulic systems, and the most common examples of material used is:

Aluminum - Lightweight, good corrosion resistance, and very good machinability of the material, (it is not as high pressure applications),

Steel (Mild or Carbon) - These grades of material are high tensile, high strength, and very resistant to damage in high-pressure applications and popping.

Stainless Steel - Superior corrosion resistance for harsh Environment factors like in marine systems food processing etc.

Surface Finishes - There is also the requirement for surface finish of sealing surfaces so as to eliminate leaks in those regions.

After the completion of the type and number of parts are determined, the digital drawings of the parts are translated into a form whereby they are capable of being manufactured on the CNC type of machining centers, on a modern center using CAM (computer aided manufacturing) software, which utilizes the digitally produced file to generate the tool paths for these modern CNC machining centers.

2.) Preparation of Material and Fixturing

A large solid of the material that is selected for the manifold is then inspected and cut to the required rough size required as per the design. The raw blank is then fixtured securely to the bed of the CNC machining center. The fixtureing of proper methods of fixtureing is generally one of the most important part of the machine finishing operation, as there are invariably considerable forces experienced in high speed machining. The bulk of the component has to be rigidly fixture to eliminate vibration, which might lead to inaccuracies in the work to be performed on it and possible tool damage.

Step 3: Precision CNC Machining - The Heart of the Process

This is where the computerized design becomes a physical component. Computer Numerical Control (CNC) milling and drilling represent the basis for modern manifold production. Here is how it breaks down:

a) Face Milling: The process usually gets started with the milling of the upper and lower surfaces, and the effect is to produce perfect parallel sealing surfaces for valve mounting.

b) Drilling the Internal Network: This is the most complex phase. Using a series of special drills and gun drills (used to produce deep, straight holes) the machine causes the intricate internal passageways to evolve.

*Deep Hole Drilling: Gun drills are used in the production of long, straight holes with high precision and fine surface finish which reduces turbulence and pressure drop.

*Cross Drilling: The CNC machine drills intersecting passages from various sides of the block, the inherent precision of the CNC system ensures that these holes will join together where intended.

c) Tapping: Each drilled hole intended to support a fitting or plug has its entrance threaded by the use of tapper tooling. This requires a high degree of precision to ensure the holding-up of the thread is clean, straight and strong.

d) Cavity Milling: If recesses are needed in the manifold for cartridge valves or other non-standard components, they will be very precisely enlarged by the CNC mill.

All through this process a skilled machinist supervises the operation to see that the tools are sharp, and that the machine is working under specified parameters. The advanced CNC technology is employed, such as obtains at Falcon CNC Swiss, ensures that repeatability exists, and tolerances are achieved which are impossible of accomplishment by manual methods.

Step 4: Deburring and Cleaning - The Devil in the Details

After machining, the manifold is covered with microscopic burrs of metal, and especially at the junctions of where the holes are cross-drilled. These burrs are fatal in hydraulic equipment, as if they are dislodged, they may make their way through the system, scratching the cylinders, and clogging the valves, and eventually causing component failure.

A program of deburring and cleaning is severity necessitated:

Deburring: This can either be done manually by the use of specially devised tools, or more effectively, through the medium of the automatated process such as that of thermal energy deburring, or Abrasive Flow machining, which way is capable of reaching all of the internal passageways.

Cleaning: The manifold then undergoes a thorough cleaning which is done either with the aid of industrial parts washers, to get rid or eradicate every trace of milling and cutting due to metal chips, cutting fluid or other contaminants that have made their appearance, then dried, and sealed immediately, that it may not corrode.

Step 5: Quality Control & Testing: Guaranteeing Zero Failure

Not a hydraulic manifold leaves the works without severe tests for quality.

Dimensional Inspections: The critical dimensions are checked by use of precision measuring instruments such as calipers, micrometers & CMMs (Coordination Measuring Machines).

Pressure Tests: This is the most critical of tests. All passages are closed off, and the manifold is subjected to a greater pressure than that for which it was made, in order to ensure that no leak exists. Such a manifold as fails this pressure test is condemned.

Step 6: Final Surface Finishing and Plating (if required)

The manifold may receive a final finish, depending on application and material. The finish may be anodized finish, for aluminum (for hardness as well as corrosion resistance). It may receive plating (nickel or chrome) for steel elements.

Why Partner with Falcon CNC Swiss for Your Hydraulic Manifolds?

An understanding of how to manufacture a hydraulic manifold clarifies the need for expertise and precision. This is the area of expertise at Falcon CNC Swiss. The page you are reviewing, CNC Machined Manifold Blocks represents our pledge of service.

We employ state-of-the art CNC machining centers and centering techniques with well defined quality control methods to provide manifolds which are amongst:

• Leakage proof – guaranteed by 100% pressure testing.

• High precision – manufactured to extremely close tolerances for perfect fit and function of components.

• Durable – taken from the right material for the pressure and environmental conditions.

• Made in time – we have a quick flow through process so that when you require parts, they are delivered.

To convert a design into a reliable, effective hydraulic manifold is fine balance of engineering and craftsmanship. Falcon CNC Swiss as your supplier is selecting an associate which is committed to excellence at each stage of the manufacturing.

Would you like to commence with your manifold project? Contact us today for a quotation and let our expertise work to your advantage for your designs.