In the electronics world, effective thermal management is not an afterthought. It is a critical performance, reliability and lifetime necessity. The high point of many thermal solutions is the humble but very important heatsink. But have you ever stopped to wonder, how are heatsinks manufactured?

The answer is actually a little more complicated than you might think. The manufacturing technique chosen has a direct impact on the heatsink performance, cost and appropriateness for a given application. While mass produced extruded aluminum heatsinks are the usual choice for consumer electronics, the more critical performance industries make use of more accurate and more robust manufacturing techniques.

In this article we are going to examine the various methods for custom heatsink manufacturing, with a partly detailed examination of why CNC machined heatsinks are often the preferred route in demanding applications such as aerospace, defence, medical and telecommunications.

The Objective of Heatsink Manufacture

Before we get into the “how”, it is necessary to understand the reason “why”. The objective of any heatsink is to maximise its area in order to effectively transfer heat from a device (for example, a CPU or power transistor) into the surrounding air. The manufacture of the heatsink determines the fin density, the aspect ratio, base plate thickness, and the overall geometric complexity and these factors determine the effective power dissipating potential of the heatsink.

Common Heatsink Manufacture Processes

1. Extrusion

This is the most common and cost effective method for high volume production.

Process: A billet of heated aluminum is forced through a steel die by means of a hydraulic ram. The shape of the die determines the profile of the heatsink in cross-section and also produces the fins.

Pros: Very low production costs per unit at high volumes, rapid production time for simple shapes.

Cons: Limited to identical cross-sections available from the die, restrictions on fin aspect ratio (height against spacing), and little flexibility in design terms. Secondary operations are often needed for features such as mounting holes.

2. Bonded / Brazed Fins

This process is used for heatsinks with very high surface areas.

Process: Each fin is stamped or machined and then bonded to a separate base plate by means of thermal epoxy or, in the higher performance versions, brazed in a furnace.

Pros: Very high fin density and large overall sizes are possible, which are impossible to obtain with extrusion.

Cons: The thermal interface between the fins and the base can be a possible point of failure, and the brazed versions are more costly and involved in complex thermal cycling.

3. Skiving

This means producing a unique heatsink in one piece with very thin and tightly packed fins.

Process: With a special skiving tool, thin layers of the metals are peeled off a solid block of copper or aluminum with the fins being bent upwards. Out of this comes a single and continuous piece of metal for the base and fins.

Pros: Excellent thermal performance due to a seamless base-to-fin interface and high fin density.

Cons: Usually only limited to softer metals (copper) and the process may be more costly than extrusion. Design flexibility is also somewhat hampered.

4. Stamping

Used for low-cost, low-profile heatsinks.

How the Process Works: Sheetmetal stamping made into a specific fin geometry. Stacks of stamped parts can be added together and joined to create greater surface area.

Pros: Incredible low cost and very high speed in mass production.

Cons: Very limited thermal performance, not good for high power.

Scalpel Precision: CNC Machined Heatsinks

For prototypes, low-to-medium volume production, and where performance and reliability are uncompromising, there is no alternative to CNC machining. How is a heatsink made by CNC?

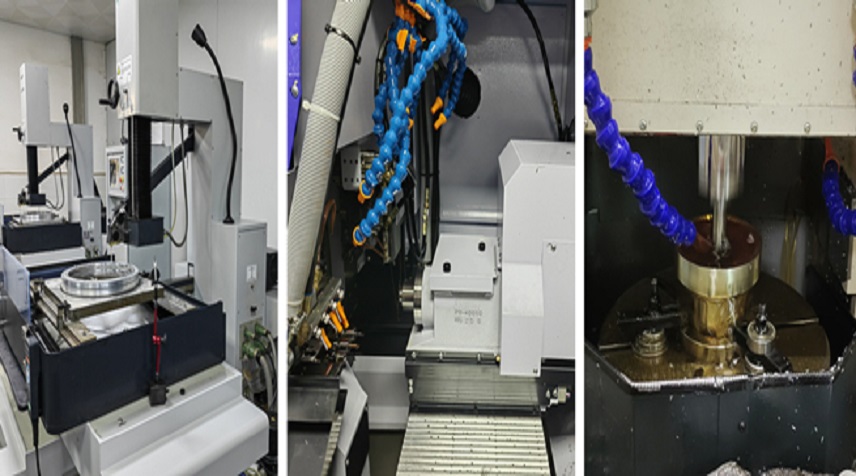

At Falcon CNC Swiss we manufacture CNC machined heatsinks on state-of-the-art 3, 4, and 5-axis CNC milling machines (the kind with a round rotating spindle) which allows a solid block of material (normally aluminum or copper) to be machined to incredible precision to manufacture a high-performance heatsink.

The CNC Machining Process for Heatsinks:

Design & Programming: A 3D CAD CAD model of the heatsink is created. Then our engineers and CAM (computer-aided manufacturing) use a series of programs to create the instructions for the CNC machine, i.e. the toolpaths necessary to cut the parts.

Material Selection: A solid block of material having high thermal conductivity C110 copper or 6061 aluminum is securely clamped or held in the CNC place.

Precision Machining: The machine then runs according to the programmed requirements removing material in a series of rotations of each cutting tool in a systematic way. This allows

1) Complex thin fin geometries having high aspects ratios to be machined.

2) Precisely mounted holes and tapped threads for mounting

3) Different geometries on the dedicated motor mounting.

4) Integrated mounts like brackets and housings manufactured in one part.

5) Secondary finishings which can include deburring, smoothing of surfaces, coatings (for example, anodizing in case of aluminum) to improve corrosion resistance. Indicate thermal emission in applications.

Why CNC Machined Heatsinks?

While not the cheapest option when mass producing millions of units, the benefits of using CNC machined heatsinks are of unmatched benefits:

Thermal Performance: A CNC allows heatsink to be milled solid from a block of solid metal, removing away the advantages of thermal interfaces so common in other heatsink designs having joint parts (where the thermal conductivities are not as fast for collecting heat from the base to the tips of the fin.)

What is the best Heatsink Manufacturing Process for You?

The best type of process depends on your needs:

Extrusion is best for high-volume and low-cost needs for simple and regular cross-sectional shapes. Bonded fins are best for manufacturing very large heatsinks or those with very large fin densities.

Stamping is applied to low-cost, low-power consumer items. CNC Machining is the one and only method to achieve high performance, custom, and precision heatsinks. These are needed for prototypes, aerospace, medical equipment, and high-power electronics.

Partner with Falcon CNC Swiss for Custom Heatsinks. Knowing how heatsinks are made is only step one. The next step is finding a manufacturer that can guarantee you performance and proven methods of manufacture.

Falcon CNC Swiss specializes in manufacturing CNC machined heatsinks to meet and exceed even the most difficult thermal management problems. Our capabilities and knowledge of all aspects of manufacturing machines enables us to manufacture complex, dependable, and well-designed products that fit your specifications for operation most accurately.

Ready to solve your most difficult thermal problems? Call us for a consultation on your project and a prospective quote on a custom CNC machined heatsink that can guarantee success.