The Unmanned Aerial Vehicle (UAV) and drone industry is rapidly advancing from a hobbyist space to a main focus of technology in today’s society. From delivery systems and infrastructure inspection, to defense surveillance and agriculture surveillance, the requirements placed on these craft are overwhelming. At the center of any high-performance UAV is a set of components that is an “all-or-nothing” proposition. It is where precision machining science make this not just a manufacturing process, but a cornerstone of innovation.

For engineers, purchasing professionals, and business leaders in aerospace and defense it is critical to realize there’s extraordinary value in the collaboration of cutting edge manufacture and UAV design. This article will breakdown the engineering and commercial reasons that high performance UAV components are necessary.

Engineering Reasons: The Engineering Reasons Why Tolerancing is Important

UAV’s are used in ever-changing, often unpredictable environments. Their stability, performance, and ultimately, success depend on the performance of the foundation. Off-the-shelf parts do not have the steady consistency for these critical applications.

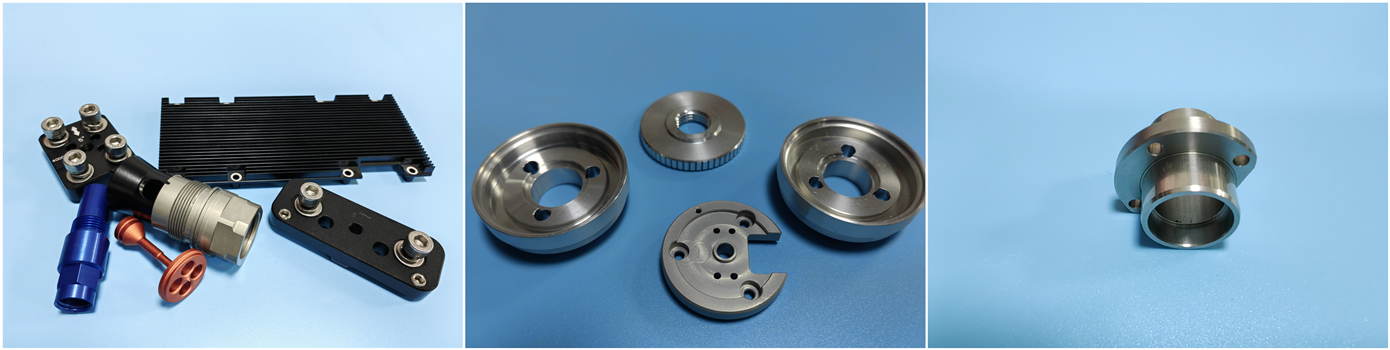

Notable UAV components that should be made from MAX CNC machining include:

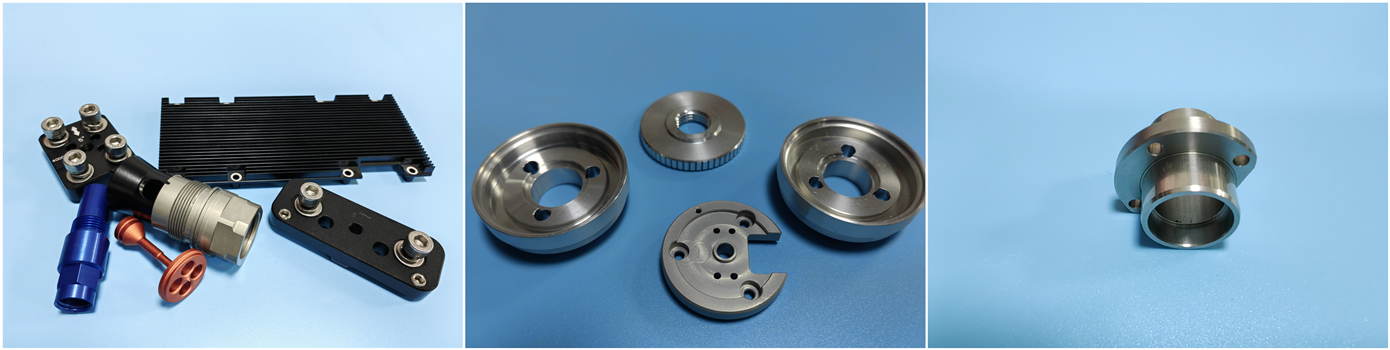

Motor Housing: Your intending to make the perfect concentric float, which means your propeller will be steady, and your vibration will be really low. The resulting HOTSPOTS will burn up down the road, wasting power and accelerating failure to your bearing.

Propellor Hub’s/Adapter’s: The relationship between the motor and propeller is often the single most critical vibration node from the fly side. An error in your props hub can cause you to idle out sending images that are not usable and tire down the damage to your expensive frame.

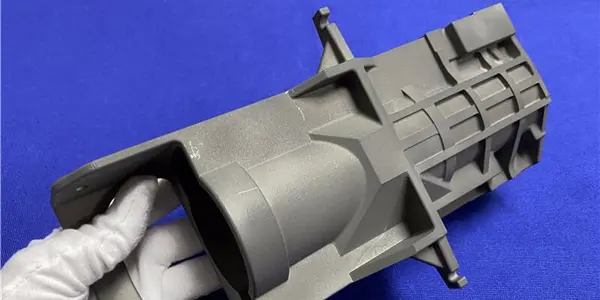

Gimbal’s Mounts, Actuators Housings: For UAV’s tasked with cinematography or surveying, securing the camera is imperative. Therefore, tight tolerances, and smooth surface finishes are key for those micro-second of flight when you can make still and grab images with fidelity.

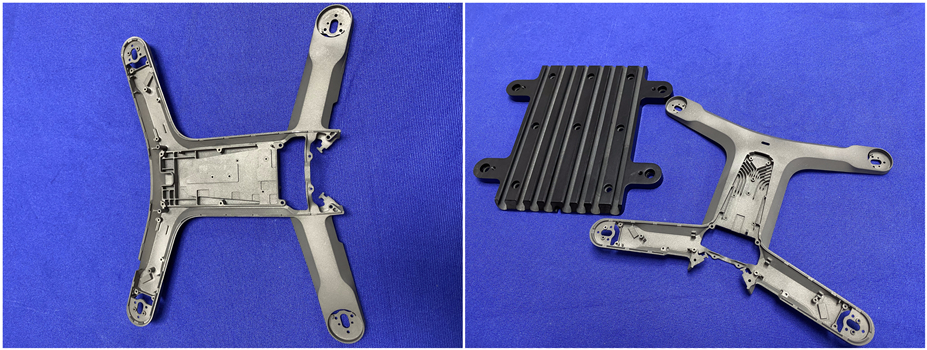

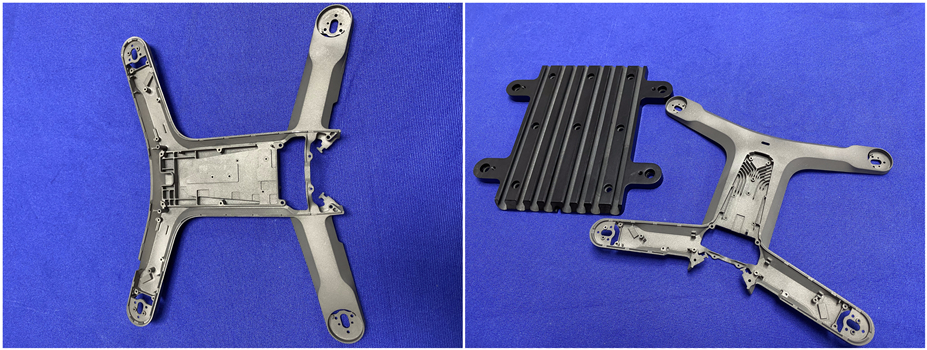

Landing Gear and Framing Structural Components: Your weight-to-strength ratio optimization will only come from CNC machined precision parts. Complex geometries maximize strength, and lightweight design will yield the performance you desire from flight time and payload capacity.

Avionics Enclosure and Heatsink: Protecting the performance of your sensitive flight controller/communication systems is non-negotiable. Custom machined parts will perform better for EMI shielding, and thermal properties than comparable parts that are molded.

The Science of Materials: Choosing Alloys for the Sky

Selection of materials is as important - if not more important - than the process of manufacture. Precision machining services are focused on working with advanced materials, which adhere to the rigid specifications of the aerospace industry.

Aluminum Alloys (6061, 7075): The bread and butter of the UAV industry, these alloys are valued primarily for their high strength-to-weight ratio, good machinability, and excellent corrosion resistance. 7075 aluminum is frequently specified for highly stressed structural components.

Titanium (Grade 5, Ti-6Al-4V): For the most demanding applications related to aerospace and defense, titanium has unmatched strength and corrosion resistance at a density of approximately half that of steel. Titanium is ideal for critical load-bearing structures, where excessive weight reduction is vital to the success of the mission.

Stainless Steel (304, 17-4PH): Specific fasteners and shafts are often required to operate in high-wear environments, necessitating a component with high durability and wear resistance, and/or magnetic characteristics. 304 stainless steel retains good corrosion resistance while 17-4PH performs excellently in the wear-resistance category.

Engineering Plastics (PEEK, Ultem): These high-performance thermoplastics have tremendous strength-to-weight ratios and offer exceptional electrical insulation and chemical resistance. Excellent for non-conductive structural applications, and hardware (avionics mounts, etc.).

The Cutting Edge: CNC Swiss Machining for Precision

Multi-axis CNC milling is very capable, but for many small, intricate drone components, CNC Swiss machining provides distinct advantages. This process stems from the watch making industry in Switzerland and is uniquely suited for long, slender & intricate parts that are typical of UAV’s.

Advantages of CNC Swiss machining for drone components:

Ultra-Tight Tolerances: The swiss screw machine provides superior stability from guiding the bar stock through a guide bushing; deflection is minimized and consistently holding tolerances can be achieved within ±0.0005” or better.

Better Surface Finishes: Stability combined with high-speed machining means surface finishes are exceptionally smooth, requiring no or minimal secondary operations while providing better part performance.

Complex Geometry in One Setup: Modern CNC Swiss lathes are up-fitted with live tooling and multiple axes to accomplish complex milling, drilling, and cross-working operations in one automated cycle, thus minimizing lead times, and preventing error stacking from multiple set-ups.

More Efficient for High-Volume Production: The bar stock is fed continuously, which makes CNC Swiss machining perfect for high-volume production runs that the commercial drone/aviation industry requires, ensuring consistency amidst 1000’s of part’s.

Market Insights: The Business Reasoning for Precision

From a commercial point of view, high-precision UAV and drone components are an investment decision with a predictable ROI:

Higher Reliability, Less Downtime: For commercial operations, such as pipeline inspections or agricultural spraying, one drone failure means lost income, and even costly recovery operations. Precision manufactured parts substantially reduce the chances of an in-flight mechanical failure.

Gain Performance and Payload: Less mass off loads are directly proportional to longer flight times (and/or improved payload). Drones can mount more complex sensors and fly larger geographical areas on a single charge, creating a direct competitive advantage.

Reduced Time-to-Market: Finding an experienced precision machining company that specializes in the UAV industry allows the prototyping and production to be accelerated significantly. The DFM benefits of their expertise can produce an effective design, thereby reducing costs and decreasing time-to-market.

Certification and Qualification: Defense and aerospace parts require certification and stringent traceability. An experienced machining partner will provide you with full material certifications and operating under the AS9100 quality management standard, required for business in these regulated industries.

Conclusion: Stand Out in the Market

The future of drone technology relies on advancements in precision cnc manufacturing. The differentiation from generic parts to precision, specialty manufactured parts, allows for the differentiation between amateur-grade devices and professional-grade products. For manufacturers wanting to be in the forefront of UAV and drone manufacturing, the selection of your manufacturing partner is paramount.

At Falcon CNC Swiss, we focus on precisely manufactured, mission-critical components. With expertise in CNC Swiss machining and multi-axis milling and knowledge of aerospace quality materials, we can make lightweight, durable, and complex parts required by modern drones. We are more than just a supplier; we are an engineering partner committed to developing a more reliable, efficient, and successful UAV systems.

Ready for better drone performance? Contact Falcon CNC Swiss today to discuss our component requirements and get your quote.