When it comes to manufacturing and complex assembly, every part is important, but while eye-catching gears and large housings tend to steal the show, often some of the smallest precision machined parts shoulder the most weight and importance.

Don't be fooled by its simplicity, the custom dowel pin is an engineering wonder and it has one function: alignment and repeatability. Getting it wrong, can result in catastrophic assembly failures, misalignment, and expensive product returns.

At Falcon CNC Swiss, we know that real precision is not just the main show, it is about being precise with every little part that contributes to the whole. Let's take a look at why custom dowel pins are essential and the direct impact on their quality on the integrity of your product.

What are dowel pins?

Dowel pins are rigid cylindrical mechanical fasteners (similar to screws and bolts) yet perform an entirely different function for fasteners. A dowel pin secures two or more components together, in perfect alignment. Unlike screws or bolts that hold parts together using clamping forces, dowel pins help ensure location precision by installing pins into matching holes in each component. This identification ensures that every time the components are assembled and disassembled, aligned in the exact same position.

Dowel pins are one of the most common precision machined parts and are manufactured to very tight tolerances (often ±0.0001 inches) to guarantee a perfect slip, press, or lock fit.

Common Applications of Custom Dowel Pins

Why would you need a custom dowel pin? Off-the-shelf dowel pins fit quite well for the majority of applications but sometimes custom solutions are warranted for the project at hand. Here are just a few critical examples:

Jig and Fixture Alignment - when configuring manufacturing set-ups, jigs and fixtures must be positioned within microns. Custom Dowel Pins provide that repeatability and if the fixture is capable of delivering, the repeatability of quality for every part produced with that fixture.

Aerospace and Defence - these industries require no exceptions. Custom pins with selected materials (often stainless steel, or hardened tool steel) that can withstand movement from extreme stress, vibration, and temperature.

Medical Devices - many surgical instruments and diagnostic devices will use a miniature custom dowel pin in an alignment process in an extremely small complex assembly where everything must perfectly fit based on a zero-tolerance for error.

Automotive - transmission and engine alignment of complex assemblies of gearboxes, housings and engine blocks is critical to performance and life cycle. Dowel pins represent that alignment.

The Falcon CNC Swiss Advantage: Precision Beyond the Pin

It’s easy to machine a pin. But, machining a pin that performs its intended purpose in its intended environment for the life of a product is not simple.

Falcon CNC Swiss is uniquely positioned to offer you the best precision machined parts, including custom dowel pins because of:

Unparalleled Material Knowledge: We don’t just machine metal. We create solutions. We can help you find the right material, whether it’s stainless steel for corrosion resistance, alloy steel for strength, or brass for non-magnetic applications.

Swiss CNC Precision: Our Swiss CNC lathe machines are capable of producing your small complex, and unbelievably precise cylindrical parts, like dowel pins. You can be assured that you will also have the surface finishes and tolerance required for a perfect fit.

Secondary Operations: A pin is only half finished once it has been turned. We conduct a complete range of secondary operations in-house including heat treating (hardness), grinding (the ultimate in accuracy), and plating (think zinc or nickel for corrosion protection to increased durability).

Quality Assurance: Each batch of your parts (including the smallest pin) will be quality checked, so no job leaves the ‘shop’ without our assurance. We'll check dimensions, hardness, and surface finish to ensure they meet your plans and specifications.

More Than Just Pins: Your Full Service Precision Machining Partner

While custom dowel pins are a significant specialty, our services extend well beyond. We are your full-service providers for all aspects of precision machined parts!

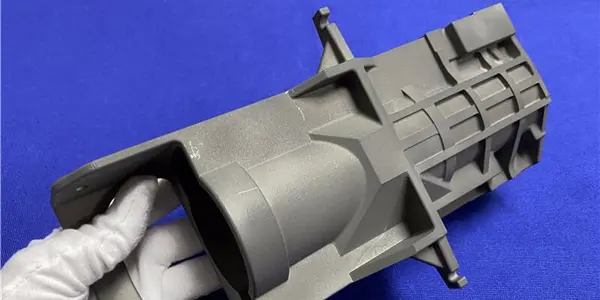

Check out our complete array of Swiss Machined Components: From connectors and fittings with complex geometries to highly sophisticated components for the medical device sector, our experience with Swiss machining allows us to produce highly complex parts both accurately and efficiently.

Learn More: Swiss precision machined parts

Specializing in Precision Pins and Shafts: Our commitment to cylindrical components can be either seen or felt through the specialty division of pins and shafts. We manufacture anything from simple guide pins to complex stepped shafts with either threaded ends; or complex geometries.

Learn More: Precision Pins and Shafts

Don't Let a Small Part Turn into a Big Problem

In mechanical engineering, the entire assembly is only as good as the least reliable part. There are no such things as “cheap” precision machined parts such as custom dowel pins; when you can invest in your final product, which will support reliability, performance, and your reputation.

Need to guarantee perfect alignment in your next job? Please contact the experts at Falcon CNC Swiss right away; when you do, we can discuss your actual application requirements and provide a quote for your precision machined dowel pins and components.