When it comes to manufacturing, two areas of precision and reliability are Swiss machining products and custom fasteners. While they may be seen as standalone items, there is a symbiotic relationship between them. Fasteners especially exotic titanium fasteners are some of the most challenging applications for CNC Swiss machining products, as these are considered high-performance and mission-critical parts.

But your unique project requires a custom screw that is either complex, mini, or extraordinary strong? This is where a specialty like Swiss Machine Products Inc. provides unmatched capabilities.

The Power of Precision: What Is Swiss Screw Machining?

Before discussing fasteners lets define the technology we are referring to. Swiss screw machining, or CNC Swiss turning, is a type of precision machining that can produce small, complex, and very accurate parts, at high volumes.

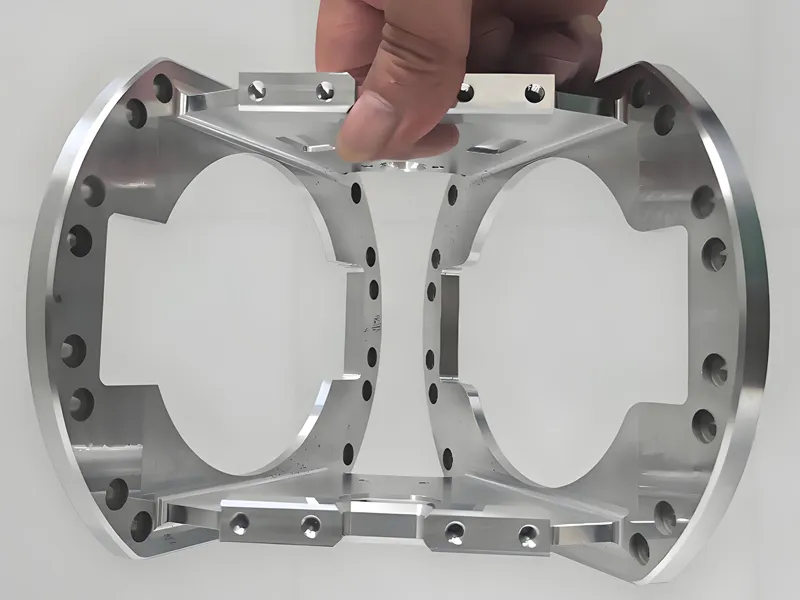

Unlike traditional lathes, a Swiss machine supports the workpiece near the cutting tool using a guide bushing. This design removes deflection and permits tight tolerances, complex features, and beautiful finishes on thin parts. It is a perfect process for creating a large list of Swiss machining products: medical daggers, aerospace connectors, and everything in between.

The Perfect Pairing: Swiss Machining For Custom Fasteners

When you need custom fasteners beyond what is typically stocked, not every manufacturing process is created equal. Here is why Swiss machining is the best option:

Unmatched Complexity: Need a bolt with internal channels, a specialty drive system, or customer threading? You can count on Swiss machine multiple ways to create by milling, drilling, and turning all in the same part setup. There geometries possible in the Swiss machining environment that other processes simply cannot accomplish.

Total Consistency & Volume: The Swiss process is made for producing many units with the same quality, Once the machine is programmed and set up it will produce the same custom fasteners thousands of times, with virtually zero variance, making sure that every part meets your specifications.

Hands-On Materials: The important aspect for titanium fasteners, is that titanium is strong, lightweight, and corrosion resistant which makes for excellent fasteners, but cannot be machined easily because it makes poor thermal conductors and has a tough tendency to gall. Good, experienced CNC Swiss machining products provide should have the know of tooling, types of coolants and the strategies to remove titanium and exotic alloys without destroying the material, as difficult materials like titanium softens and loses these properties if you overheat the material or use an improper coolant.

Why You Should Demand Swiss Precision for Titanium Fasteners

Titanium fasteners are the go-to choice for aerospace, medical implants, and high-performance racing applications because there is no re-work possible. Failure is not an option! The margin for error in these applications is zero. It is at this critical juncture that the Swiss machining process excels:

Holds critical tolerances: Perfect thread engagement and tensile strength must be guaranteed.

Superior surface finish: Lower friction, fewer crack initiation points.

Material integrity: Heat and cutting forces to control work hardening and micro fractures causing a weak fastener.

You can never go wrong when you select a manufacturer that is experienced in both production of Swiss screw machine products and an understanding of exotic materials - titanium is no exception.

Finding Your Right Manufacturer: It is More than a Machine

The selection of a vendor for your Swiss machining products is a major decision. Finding the right relationship should take into consideration several features, including:

End-to-End capabilities: from the initial design consultation to finishing, plating, and inspection.

Thorough quality inspection: critical in-class inspection as well as final inspection using CMMs and other metrology tools.

Experience with materials: a demonstrated track record of successfully completing machining with titanium, stainless steels, plastics and other engineered materials.

Your Manufacturer for Precision Swiss Machined Components & Fasteners

At Falcon CNC Swiss, we thrive at the intersection of precision and performance. We know we are not just another machine shop. We consider ourselves to be problem-solvers for our customers. Producing, the highest quality, CNC Swiss machining products used in industries where failure is not an option.

Our expertise = your advantage. Whether you require a complex component for a medical device, or a high-strength titanium fastener for a satellite, we have both the technology and talent to deliver.

Are you ready to see what precision can do for you?

Discover our extensive capabilities and see examples of our work in our gallery of precision Swiss Machined Components.

Are you specifically looking for fasteners? Check out our Bolts and Nuts folder where we have custom and standard components manufactured to the highest standards.

Contact Falcon CNC Swiss to quote your project and let’s start our partnership to make your most difficult designs a reality!