In the never-ending quest for manufacturing excellence, where tolerances can be specified in microns and where the failure of parts is unacceptable, one technology has emerged heads and shoulders above the rest for the ability to produce highly complex, small and super precise parts: Swiss machining.

You may have heard of CNC Swiss machining, but if you have ever said to yourself, "What is CNC Swiss machining really?" or "How does it differ from traditional CNC turning and milling?" you have come to the right place. This comprehensive easy to read and understand article will reveal all the mystery of the process. Additionally, we will highlight how this technology can be used to your advantage and cover the industries that rely upon this process as well. Most important of all, we will show how absolutely critical it is to work with an expert CNC Swiss machining company in your next project.

The Secrets Of How Swiss Machining Really Works

At the heart and soul of CNC Swiss machining is a highly advanced derivative of CNC lathe machining. However, it is the operating principle itself that differs significantly and enables the type of precision that can be attained, especially on long slender parts.

With a conventional lathe, the part is held stationary or actually turned between a head and tailstock. The cutting tool actually comes in to perform the cuts. This can cause deflection and vibration on long, slender parts and destroy any accuracy.

A lathe made on the Swiss principle (also known as a Swiss screw machine) entirely alters this picture. The material bar stock (generally speaking, not over 1.25 inches in diameter) is held securely with a collet in a guide bushing. The cutting tools are located around the part. Therefore, while the part is being machined, the guide bushing and the material bar stock slide and turn in the Z axis, resulting in the part being moved into the stationary tools.

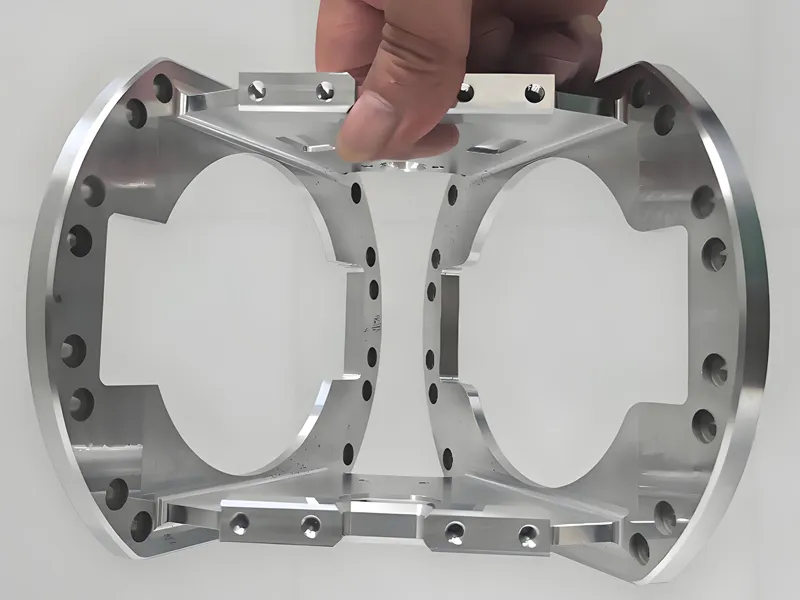

This method of using manageable material supply gives immense support to the piece being machined immediately adjacent to the cutting point. The result of this is little if any deflection, vibration, or what is known as "chatter," which allows for the production of parts having length-to-diameter ratios that are unthinkable with a conventional lathe. Virtually all modern CNC Swiss machining plants utilize sliding headstock machines having live tools and secondary spindles, enabling complex milling, drilling and cross working in a single automatic cycle or setup. This gives a wonderful demonstration of their capabilities as a CNC Swiss machining source of contract manufacturing.

Key Benefits of Precision CNC Swiss Machining

The question comes up: Why would an engineer specify the use of CNC Swiss machining as a means of producing parts vs. other available better methods of CNC machining? The reasons are of significance, and directly impact the quality, efficiency and cost of a product manufactured on the Swiss principle.

Incomparable Pertinence of Tolerances and Surface Finish: The guide bushing support system for parts produced is the key to attaining tightly held tolerances, often as great as ±0.0002 inches (±0.005mm). The resultant reduction in vibration produces an incredible surface finish right off the machine, often with secondary finishing operations being entirely eliminated.

Great Efficiency in the Production of Complex Parts: Modern CNC Swiss machining companies use machines having multiple axes, live tooling, back working spindles etc. This means that a part can be completely finished in one cycle (front, back and sides) without having to be manually moved to another machine for finishing. This means drastically reduced machine cycle time, labor cost and the incidence of the possibility of human mishandling or error is entirely eliminated.

The Best Applications for CNC Swiss Machining: Small, Thin And Complex Parts: This is where Swiss machining shines. If your part has complex features, drilled holes, fine threads, or an extreme length-to-diameter ratio, precision CNC Swiss machining is almost certainly the best process of choice.

Minimal Material Waste: The incremental feeding of bar stock means that only the material needed for the part is consumed, minimizing waste. For high production of expensive materials such as titanium or medical-grade stainless steel, the efficiency involved results in substantial saving in costs.

Swiss vs. Conventional CNC Machining: Choosing the Right Process

It is important to understand the difference so that you can select the right contract manufacturer that offers CNC Swiss machining and the right machining process for your project.

| Feature | CNC Swiss Machining | Conventional CNC Turning |

| Workpiece Support | Guide bushing supports material at cutting point | Supported only at ends (headstock/tailstock) |

| Part Geometry | Excellent for long, slender, complex parts | Better for shorter, stouter parts |

| Complexity | High; can perform turning, milling, drilling in one setup | Lower; often requires secondary operations |

| Tolerances | Extremely tight tolerances achievable | Good, but can be limited by part deflection |

| Efficiency for Volume | Highly efficient for high-volume, complex parts | Efficient for simpler parts in high volume |

Simple rule of thumb: If your part is long, skinny, and needs complex features, CNC Swiss machining is the answer. If your part has a simpler, sturdier geometry, then conventional turning might be the better solution in terms of costs.

High-precision CNC Swiss machining services in industries revolutionized by them

The characteristics of Swiss machining make it indispensable in a number of industries involving a good deal of stress or where failure is not an option.

Medical and Surgical: This is where precision CNC Swiss machining parts are needed most. Bone screws, surgical drill bits, all manner of complex parts for implantable devices, including robotic surgery arms — the need for materials that are biocompatible, for surfaces that are perfect and for total precision is filled very well by Swiss machining.

Aerospace and Defense: The aerospace industry utilizes high-precision CNC Swiss machining services for vital components such as engine fuel-injector nozzle, sensor housings and actuators. These components have to be able to withstand extreme temperatures and pressures and still be absolutely reliable.

Electronics and Connectors: The miniaturization of electronic devices requires extremely small complex parts, screws, pins, connectors, etc. CNC Swiss machining shops produce these parts with the precision necessary and often in the great amounts required by the electronic industry.

Automotive: Especially with high-performance racing and fuel-injection systems, Swiss machines in the production of small, durable parts such as valves, shafts and sensors which help contribute to engine efficiency and performance. How to choose a CNC Swiss machining partner: Not all machine shops are created equal. When your project requires the unique capabilities of Swiss machining, it is of utmost importance to select a suitable partner. Here are some points you should look for in a company skilled in CNC Swiss machining:

Your Guide to Selecting a CNC Swiss Machining Partner

Material Knowledge: Specific experience with the materials that comprise your CNC Swiss machined parts is essential for the contract manufacturer you choose. Be sure to select a manufacturer who has expertise with your specific materials, be they of exotic alloys, medical grade titanium, stainless steel or engineering plastics.

Open Communication and Support: To ensure that your requirements are met to your total satisfaction, from the receipt of your first CNC Swiss machining quotation and continuing through to final delivery, you need a contract manufacturer who is communicative, goes out of their way to accommodate your requests and who will service add to the DFM or design for manufacturability, specifications of your product.

Falcon CNC Swiss: Experts in the field of Precision CNC Swiss Machined Parts

We do not just machine parts at Falcon CNC Swiss; we also engineer solutions. We have earned our reputation as a trusted CNC Swiss machining contract manufacturer by making good on our commitment to perform on the most demanding projects. Our state-of-the-art CNC Swiss machining factories are equipped with advanced multi-axis Swiss-type lathes and our engineers and skilled machinists are all dedicated to producing perfection in every one of the parts produced.

We specialize in producing complex high-tolerance CNC Swiss machined parts for the medical device, aerospace and electronics industries. We realize that the success of your company depends upon the reliability and quality of each of the parts that comprise your products. We are committed to being an extension of your team.

Ready to Experience the Falcon Difference?

If your are designing a part that will requires the extreme precision and efficiency offered by the CNC Swiss machining process, we would like the opportunity to partner with you in that effort. We prepare detailed, competitive quotations for our CNC Swiss machined parts in a timely fashion and are readily available to lend our expertise in optimizing your design for manufacturability and in keeping your costs as low as possible.

Check out our full range of CNC Swiss Machining Services to see how we can assist you in bringing your most difficult projects- to production. Or contact us today for free design analysis!