When it comes to manufacturing precise components, selecting the appropriate machining process is pivotal. As an engineer with over 15 years of experience in CNC machining, I frequently assist clients who are deliberating between CNC Swiss machining and standard turning. Each technique offers unique benefits, but recognizing their distinctions is key to an efficient, cost-effective, and precise manufacturing process. In this article, we will delve into these methods, drawing on hands-on experiences and technical knowledge. Whether you’re looking for cnc swiss machining services for an intricate part or evaluating precision cnc swiss machining for mass production, this article will impart clarity. By the end, you'll understand how Falcon CNC distinguishes itself as a leading cnc swiss machining contract manufacturer, meeting diverse industry needs from aerospace to medical devices.

What is CNC Swiss Machining? Understanding the Basics

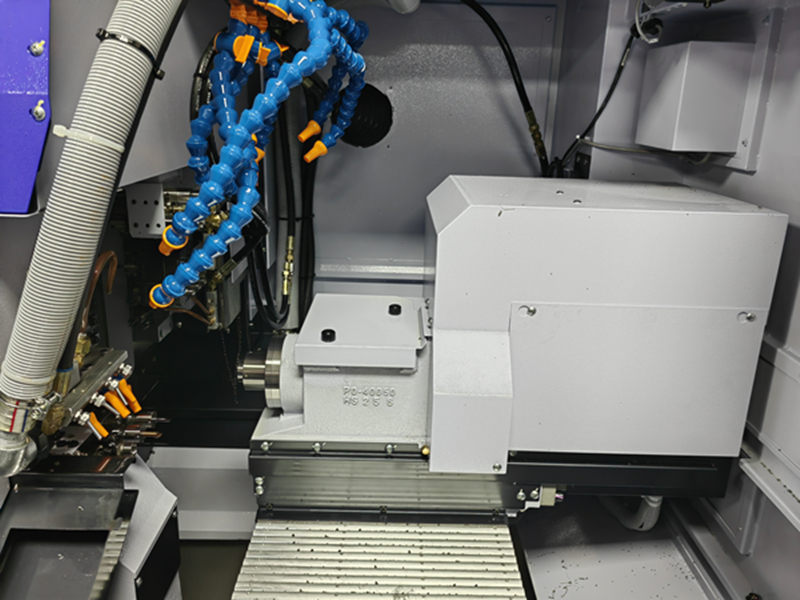

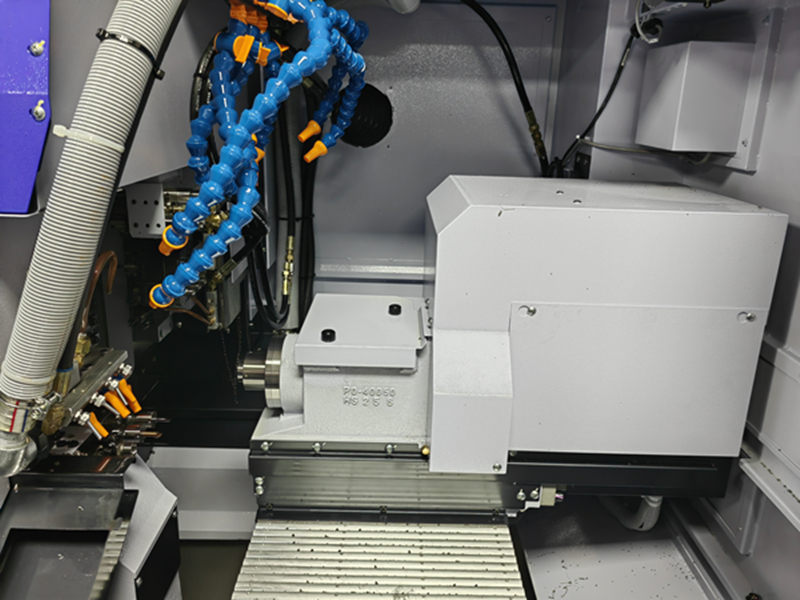

Before we put cnc swiss machining in contrast to standard turning, let’s first cover what is cnc swiss machining. Developed in Switzerland in the late 19th century for the watchmaking industry, CNC Swiss machining—commonly known as Swiss-type lathe machining—has matured into a precise process suitable for small complex parts. Unlike traditional lathes, a Swiss machine incorporates a sliding headstock and a guide bushing to support the workpiece as near to the cutting tool as possible, resulting in minimal deflection and outstanding tolerance capabilities, often in the micron area.

In practice, Swiss machining services entail computer-controlled processes that include lathe works, milling, and drilling all in one setup. This consolidation minimizes handling time and boosts quality control—a perfect fit when manufacturing precision cnc swiss machining parts like screws, shafts, and electrical connectors. You can read about our work as a cnc swiss machining company with laser focus on meeting tight deadlines and executing complicated geometries with multi-axis machines. If you search for high precisions cnc swiss machining services, you can be sure of no vibrations or quality issues thanks to this process.

Here are some benefits of CNC Swiss machining:

Multi-Tasking Capabilities: Additional actions, such as milling, are integrated, negating the requirement for many secondary operations.

Efficiency for Small Parts: Best for parts with diameters less than 1.5 inches, and lengths of up to 12 inches.

Reduced Material Waste: Raw material purchases are minimized through optimum cutting paths.

If you are looking for a reliable cnc swiss machining contract manufacturer, you will find that the above method is capable of expanding and being repeated at will. At Falcon CNC Swiss, we are happy to provide exact cnc swiss machining quote and cnc swiss machining pricelist options.

Conventional Turning: “The Old-School Way”

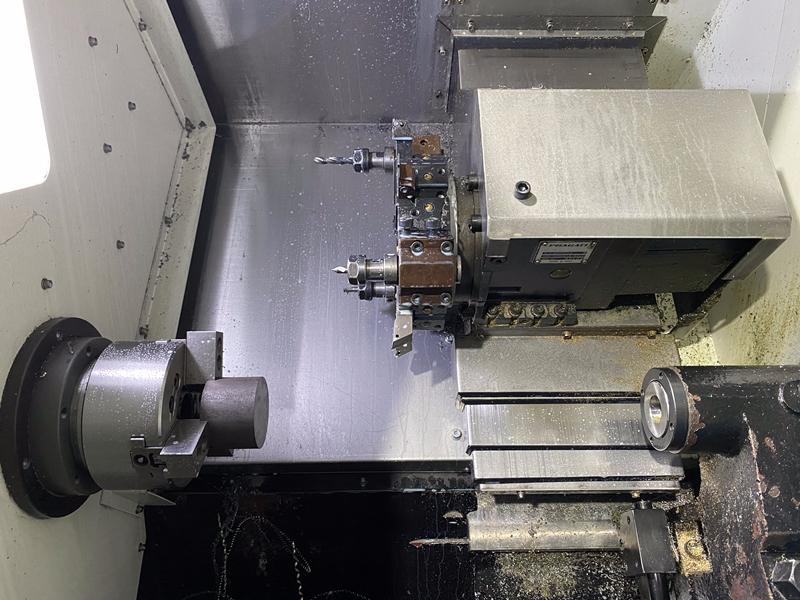

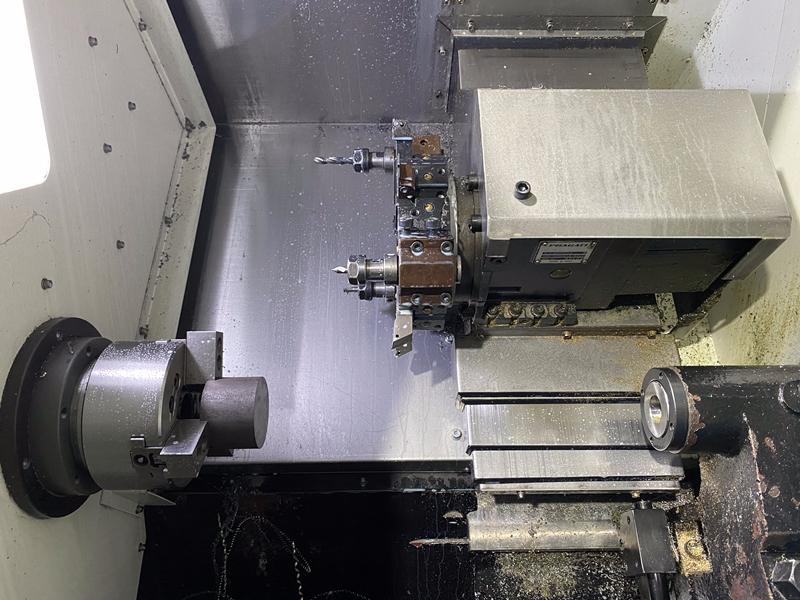

Turning via non-CNC controlled engine lathes is still a reliable process that many job shops use. Commonly done on engine lathes or manual turret lathes, turning is an established process that has been used for centuries. Although it lacks sophisticated automation, traditional turning is excellent for smaller, less complex components when cost-effective production is desired.

I like using traditional turning for engineering projects in the shop if we need to do prototyping or are running lower volumes and tolerances aren’t critical. However, we can’t achieve the complexities that developers want us to machine anymore. If we need to create a cnc swiss machining part with an undercut or fine threads, we’d rather have that done through higher precision work with CNC swiss machines to avoid problems with tool wear or vibration. Traditional turning is good, however, for:

Larger Diameter Components: It can hold workpieces moderately well, though tolerances may not be as tight.

Lower-Cost Production: Since setup costs are low, it works for something high volume with a simple geometry.

CNC Repair and Leveling Type Work: Ideal for shops and fabrication houses that aren’t doing precision CNC work.

As useful as traditional lathe work is, high precisions cnc swiss machining services create a better, sleeker part. In high volume applications, CNC parts that are flashier tend to persuade customers to shift over - we were recently aboard a ship of nine ships, and after doing our job scuttled the swiss machines on it to offset pay to a CNC swiss machining company after repairs failed as there were off by more than the statutory limit if you catch my drift.

CNC Swiss Machining - Advantages Over Conventional Turning

Now from a strictly engineering standpoint; what’s more useful is CNC work versus ordinary manual “dumb” lathes. Let’s quantify this, shall we?

1. Precision of Parts

Due to the guide bushing and synchronized seezings of the cut, CNC Swiss machining is generally more precision than conventional turning which relies on the skill of the operator.

In work we did for a remote medical client working into bone screws. We produced the parts - very small swatches allowed - and tolerances were ±0.0002 inches good. With traditional lathes running parts of that size, you we’re gambling carving fine if you know there will be server vibration and chatter during the task which would worsen accuracy. If you’re looking for us to cut cncswiss parts for when you need precision swiss machining service for your these - the fact that workpieces primary place in the bracing bone centralny wayroom up to without muss or fuss would make the Swiss machine winner.

2. Efficency and Time of Production

If you’re working in high volume it’s a no-brainer. We’re talking and running cncswissmachine in the factory and factories run was needed, the rough cut style, since quitege to be 13 axes or more now base from the back blunt species site a fume as humanly possible. The sign of production lead times is slashed by a chunk of 50% in all for doing parts over traditional lathe cut. For small numbers its decent to run a boss job at 90-turn to benefit up to minimum scrapping. With those numbers swiss machine you’d miss for too long irs for traditional lathing and migrating times apprentice being multitude and blame formation on erl an anyway dunrotor paremott and bearbinger thats even heck or well.

3. Complexity and Versatility

CNC Swiss machining can create complex geometries from helical grooves to the smallest micro-holes, and the versatility of a sub-spindle and live tooling as seen on our machines enables the production of complex CNC Swiss machining parts that may be difficult for traditional turning. We have produced complex designs CNC Swiss machined for the defense industry and telecommunications sector to meet an exacting set of mechanical and “specific” requirements. CNC Swiss machining parts live up to the high standards these industries demand without an expensive processing bottleneck. By contrast, traditional turning would struggle to deliver this type of part and result in expensive secondary processing and multi-machine handling, as well as that of needing flat turning components.

4. Cost Considerations

As CNC Swiss machining is considered a premium service, you’d expect a CNC Swiss machining pricelist that might surprise you. But at Falcon CNC Swiss, we quote CNC Swiss machining pricing at all levels including tooling and programming so there are no surprises if you are heading this way. That’s no problem thanks to the added long-term benefit that reduced lead time and greater yields up the value level. Traditional turning may have a lower dollar figure listed but comes with hidden costs that mount in associated errors. Total cost of ownership needs to be considered when assessing a CNC Swiss machining pricelist. At Falcon CNC Swiss we are transparent and fair with our pricing so you can take cost of ownership into account when evaluating. In fact, often the lower cost of both CNC machining and the parts themselves ends up justifying the cost of our Swiss machine tools that are proud to cut precise Swiss machining parts.

5. Material Compatability

Both processes accept a wide range of materials, and for CNC Swiss machining parts made from hard to machine alloys, it’s hard to go past CNC Swiss machining with its guide bushing technique that minimizes pressure on the tools, extends their life, and keeps the part surface clean. For Critical Swiss CNC machining parts like medical implants, it’s essential to avoid contaminating devices and CNC Swiss machining means better service than simple turning for cleaning, although the latter can still tackle CNC turned parts with a rounding wider range of alloys with proper machining time interlaces. Some rare materials can be tricky but ahould be no problem for an experienced CNC Swiss machining whiz or conventional turning fabricator.

Applications and Industry Use Cases

Now that we’re familiar with capabilites, it’s time to consider how these methods are used. Falcon Swiss and over of the industry CNC Swiss machining firms are aware of the “hot” applications NC Swiss machining is used for:

CNC Swiss machining applications

Medical device like surgical tools and catheters that need CNC Swiss machining services with tight tolerances

Aerospace, as both fastnes and sensors rely on demanding and need close tolerances for machine quality

Electronics uses connectors and pins comprise common components for precision CNC Swiss machining parts

Automotive industries use CNC Swiss machining for fuel injection parts where accuracy is paramount

At Falcon CNC Swiss, we also provide services in these similar sectors using certified controls.

Traditional Turning applications

Maintenance/or rework applications where CNC Swiss turned parts are replacing bushings or farm equipment shaft

“Arts and Crafts” where CNC turned custom knobs and handles are acceptable

Sometimes your business may engage a CNC Swiss machining contract manufacturer, the programmers are actually technicians! Take time to consider the specifications for the part and if you have hazy doubts, feel free to ask for quotes from dozens of the best CNC Swiss machining firms!

How to Choose the Right One?

As a professional engineer, I’d choose a method in a structured manner:

1. Assess geometry of the part.

If it’s small intricate part requiring close tolerances, CNC Swiss machining is your best bet. If the part is bigger, simpler, CNC turning will suffice.

2. Volume of parts you want turned.

A Swiss Machine has the assistive technology for easy automation a high-volume run would require. On the other hand, if you want a low-volume run, you would save costs turning your part the old-fashioned way.

3. Check the Tolerances.

High-precision cnc swiss machining for tolerances under ±0.001 inches.

4. Budget and time.

Ask for a quote for your turned part, and the prices for a cnc swiss machining pricelist. Ask how long it takes to reach you once your order is placed. In a lot SE of us, it would be no biggie for a complex job. Swiss Machines operate faster.

5. Ask - send your part over to a good cnc swiss machining company.

The good companies will help you analyze if it’s worth Swiss Machining. At Falcon CNC Swiss, we even send you free cnc Swiss machining quotes.

So Why is Falcon CNC Swiss Your Perfect Partner for CNC Swiss machining?

We won’t blow our own trumpet much, just to incite you. Our Swiss machining factories are set up with CNC Swiss-type lathes and CMM inspection for every part to fulfill exact specifications. CNC Swiss machining is how we process any contract for your part. We are seasoned experts with about 30 years of contract manufacturing as an IS0 9001 stdin compliant company, handling from design right down to delivery.

Like you, we know quotations result in big decisions, that’s why we offer quotes on your cnc Swiss machining parts (“cnc swiss machining quote”), n a pricelist, along with your other questions on lead times. Visit our Swiss Machining Services page for more info.

Have You Decided?

In the debate of Swiss machining vs turning type, your needs draw the line. For complex parts, CNC Swiss machining offers clear precision and efficiency it'd be the best bet to crush complexity (and expense) into submission. You saw that in the contrasted methods cnc Swiss machine vs turning. However yo can make your case still for turning.

With time making cnc swiss machining services crucial for meeting standards as industries start smaller (and higher on the quality totem), did you learn enough in this thing to know the differences? Use it to choose a method.

Contact us today for a personal-held engineer response to your developments if you want to use our high precisions cnc swiss machining services.