In the world of high-precision manufacturing, the difference between project success and costly failure often hinges on a single choice: your Swiss machining supplier. Whether you’re sourcing Swiss turned components for a medical device or intricate micro Swiss machining parts for aerospace, the capabilities and expertise of your partner dictate everything from part performance to supply chain stability.

This guide cuts through the marketing claims. Written from an engineering perspective, it provides a forensic framework for evaluating Swiss machining companies. We’ll equip you with the critical questions to ask, the technical red flags to spot, and the evidence-based criteria that separate truly capable partners from the rest. For engineers and procurement specialists navigating a global field of options, including evaluating Swiss machining China providers, this is your essential due diligence checklist.

Part 1: Core Technical Capabilities – The Non-Negotiables

Your supplier’s technical foundation determines what is physically possible. Look beyond brochures and demand concrete proof.

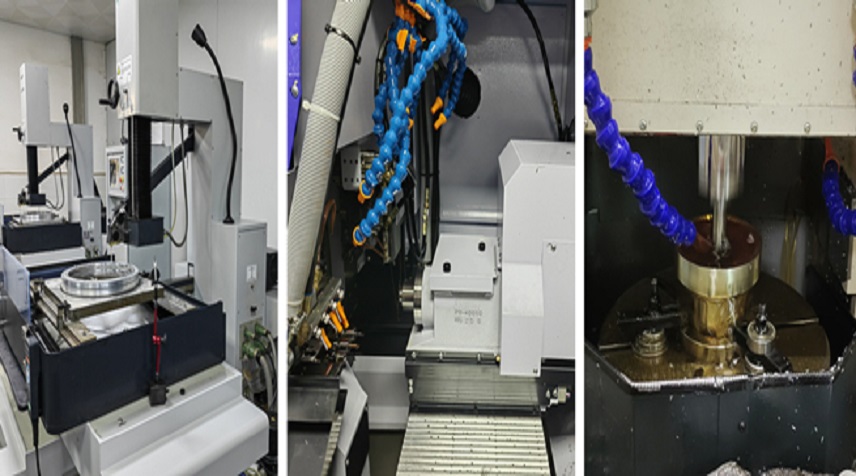

1.1 Machine Tool Arsenal & Technological Sophistication

Not all CNC Swiss machine shops are created equal. The type, generation, and condition of their machines are paramount.

Why it matters: Newer machines with live tooling, dual spindles, and Y-axis capabilities can complete complex parts in a single setup, enhancing precision and reducing cost. A shop with a range from 5mm to 32mm bar capacity shows versatility.

1.2 Specialization in Micro-Machining and Tight-Tolerance Work

If your project involves sub-millimeter features, general machining experience is insufficient.

Ask: “Can you provide case studies or examples of parts with critical tolerances below ±0.0005” (0.0127mm) or diameters under 1mm?”

Why it matters: Micro Swiss machining requires more than small tools; it demands exceptional machine rigidity, specialized toolholding, and environmental controls (temperature, vibration) to achieve stability.

Evidence of Expertise: A capable supplier will discuss their specific protocols for micro-work, such as tool runout verification, high-pressure coolant for chip evacuation, and in-process probing for micron-level accuracy. Their experience as a specialized Swiss screw machine company for miniature components should be evident.

1.3 Material Science and Application Engineering

A true partner understands how material behavior interacts with the cutting process.

Ask: “What is your experience with our Swiss screw machine company specific material (e.g., Ti-6Al-4V, 316L SS, PEEK)? Can you advise on optimal grade or temper for our application?”

Why it matters: Machining exotic alloys or delicate polymers requires tailored speeds, feeds, tool geometries, and coolants. Misapplication leads to poor surface finish, work hardening, or thermal deformation.

The Engineering Partnership: The best Swiss machining companies offer Design for Manufacturability (DFM) feedback not as criticism, but as collaborative engineering. They should proactively suggest subtle design tweaks that enhance manufacturability, reduce cost, and improve part function without compromising intent.

Part 2: The Quality Ecosystem – Beyond the Inspection Report

A certificate is a snapshot; a quality management system is the culture that guarantees consistency.

2.1 Process Control vs. Part Inspection

Inspection finds defects; process control prevents them.

Ask: “How do you control and document critical process parameters (CPPs) for each job? What Statistical Process Control (SPC) methods do you employ?”

Why it matters: A shop relying solely on final inspection is gambling. A shop using SPC monitors tool wear, dimensional trends, and machine performance in real-time, making corrections before tolerances are breached. This is especially critical for high-volume screw machine products where consistency is king.

2.2 Metrology and Traceability

The accuracy of measurement must be an order of magnitude greater than the tolerance required.

Ask: “What is the measurement uncertainty of your CMM and optical comparators? How do you ensure full dimensional traceability from billet to finished part?”

Why it matters: Measuring a ±0.0005” tolerance with a machine that has ±0.0002” uncertainty is unreliable. Look for NIST-traceable calibration and a metrology lab controlled for temperature and humidity. For regulated industries, a robust Electronic Traveler (eTraveler) or lot-tracking system is non-negotiable.

2.3 Cultural Commitment to Zero-Defect

Quality must be everyone’s responsibility, not just a department.

Evidence: Look for shop floor practices. Are tools organized? Is the environment clean? Do operators have clear, visual work instructions? Certifications like ISO 9001:2015 or AS9100 are a good baseline, but the daily discipline you observe tells the real story.

Part 3: Operational and Commercial Viability

Even the most skilled shop cannot be a good partner if its operations or business are unstable.

3.1 Project Management and Communication Protocols

Miscommunication is the root cause of most project delays.

Ask: “Who will be our single point of contact? What is your standard process for quoting, engineering review, production updates, and non-conformance reporting?”

Why it matters: You need a dedicated project engineer who understands both your technical needs and your supply chain pressures. Clear, proactive communication on milestones and potential issues is a hallmark of a professional Swiss screw machining company.

3.2 Supply Chain Resilience and Sourcing Power

A supplier’s weakness becomes your vulnerability.

Ask: “How do you manage raw material sourcing and qualification? What is your strategy for mitigating supply chain disruptions for key alloys?”

Why it matters: A supplier with strong relationships with certified metal distributors can secure material faster and at better prices. They should have contingency plans and be transparent about material lead times affecting your project.

3.3 Evaluating the “Swiss Machining China” Proposition

When considering Swiss machining China suppliers, the evaluation must be even more rigorous.

Key Considerations: Beyond technical capability, assess their experience with international logistics, export documentation, and IP protection protocols. Do they have a track record of serving Western OEMs directly? What is their true command of technical English in engineering discussions? The lowest price is meaningless if it comes with hidden costs of poor communication, shipping delays, or quality disputes. Look for a partner like Falcon CNC Swiss, which bridges this gap by combining advanced technical capability with dedicated international project management

Part 4: Making the Final Decision – A Practical Checklist

Use this consolidated checklist during your RFQ process and facility audits.

Evaluation Category | Key Questions to Ask | Evidence to Request |

Technical Capability | – Bar capacity and machine tool list?

– Micro-machining (<1mm) experience?

– Live tooling/Y-axis for complex parts? | – Machine list with models.

– Sample parts matching your complexity.

– Video of a complex part running. |

Quality & Precision | – SPC/process control methods?

– Metrology equipment and uncertainty?

– First Article Inspection (FAI) report format? | – Sample SPC chart from a past job.

– Calibration certificates for CMM.

– Sample FAIR (e.g., AIAG PPAP). |

Engineering Expertise | – DFM feedback process?

– Experience with our specific material?

– Handling of non-conformances? | – Case study of a DFM improvement.

– Material-specific cutting parameters.

– NCR process flow document. |

Operations & Commercial | – Project communication protocol?

– Raw material sourcing strategy?

– Capacity and lead time realism? | – Define a sample communication plan.

– List of certified material suppliers.

– Current shop capacity loading overview. |

Conclusion: Partnering for Precision

Selecting a Swiss machining supplier is an investment in your product’s quality, reliability, and ultimately, your brand’s reputation. By moving beyond price-per-piece to a holistic evaluation of technical capability, quality ecosystems, and operational excellence, you secure a true manufacturing partner.

The right supplier acts as an extension of your engineering team, mitigating risk and adding value at every stage. They transform from a vendor into a strategic asset, enabling innovation and ensuring your most demanding Swiss turned components are produced flawlessly, batch after batch.

Ready to Partner with a Supplier That Meets This Standard?

At Falcon CNC Swiss, we are built on the engineering principles outlined in this guide. We invite you invite you to review our comprehensive Swiss Machining Services page to detail our capabilities. Contact our engineering team today to discuss your project and experience a partnership defined by precision, transparency, and results.