Introduction: The Titanium Challenge in Precision Machining

In the cutthroat world of precision manufacturing, few materials loom as both temptress and dragon as titanium. For engineers designing the next generation of aerospace parts, life-saving medical implants or super-high-speed racing components, titanium’s strength-to-weight ratio, corrosion resistance and biocompatibility are second to none. But the raw titanium bar into a tough-as-nails, looping-swooping, micron accurate component is that of a special blend of machine, tooling and expertise. This is where the precision of Swiss machining titanium becomes not just an option, but a necessity.

We, at Falcon CNC Swiss, serve the good of our engineering society by developing that knowledge. As a leading Swiss machining titanium machine shop, we know success happens on the foundation of fundamentals of how the cutting tool interacts with titanium. Written from the engineer’s workbench, this guide tackles the elements of titanium Swiss screw machining is for you.

Why Titanium? The Material Motivators for Swiss Machining of the Element

There’s an old adage in technology; before one concerns themselves with the “how,” they need to understand the “why.” Titanium isn’t selected for its easiness to cut; it is cut because the application demands it.

Strength to Weight: Titanium, depending on the grade, offers comparable strength characteristics to many steels, at nearly half the weight making the material ideal for aircraft brackets, fasteners and anywhere weight of a rotating or payload matters.

Corrosion Resistance & Biocompatibility: Common machining grades such as Ti-6Al-4V (Grade 5) are inert within the confines of the human body, and resist corrosion from bodily fluids and sterilization making the material ideal for surgical tools, implantables and dental products.

Heat Resistant: Titanium retains its mechanical properties at temperatures where aluminum alloys can weaken making it a suitable candidate for aerospace components adjacent to engines.

Non-Magnetic & Low Thermal Conductivity: desiring to calibrate small electronic or scientific devices.

The challenge, however, lies in the very attributes that make titanium a superb material. Titanium’s low thermal conductivity means that with an insufficiently aggressive feed rate and depth of cut, heat tends to stay at the cutting edge not fully transferring to the chip, leading to rapid wear. Its augmented strength means that considerable force is required to cut the metal and this, coupled with the natural tendency towards work hardening, can mean poor surface finish and tool failure if not properly accounted for.

The Swiss Solution: Why a Swiss-Type Lathe is Perfect for Titanium

When it comes to small titanium parts Swiss machining, nothing brings the goods like a Swiss-type lathe. This particular breed of CNC lathe expertly sidesteps the major machining issues titanium presents:

Support Like No Other: The lathe’s guide bushing supports the workpiece mere millimeters from the cutting action. That support matters deeply when machining the long, slender parts characteristic of titanium swiss screw machining, like pins, shafts, and fasteners. To prevent chatter and poor tolerances in this notoriously difficult alloy to machine, you need rigidity in your lathe.

Hot to Trot: The guide bushing’s proximity and the ready availability of high-pressure coolant directly to the cutting interface aids in dealing with titanium’s heat issue. Heat evacuation is key to maintaining tool life and dimensional stability.

Axis Synchrony: Modern CNC Swiss lathes combine live tooling and secondary spindles for full machining of precision swiss machining titanium parts in a single setup. Eliminating handling of a costly, partially finished titanium part enhances yield, consistency, and throughput.

A Deep Dive into Titanium Grades for Swiss Machining

Now we take a deeper dive into the question of titanium grades suitable for Swiss machining. Not all titanium, of course, is the same, and making the call on what grade to use is the first important decision on any project.

Commercially Pure Titanium (grades 1-4): Softer and more ductile than alloys. Work easier to machine, but no stronger. Used for corrosion resistant plates, tubes, and some medical applications where maximum formability is needed.

Ti-6Al-4V (grade 5): The workhorse of the titanium alloy world, Ti-6-4 accounts for almost half of all titanium used. Excellent balance of strength, weight, and corrosion resistance. Swiss machining titanium grade 5 is the most common request we get for aerospace, medical, and automotive performance work. Machinability is fair, and requires moderately disciplined parameters.

Ti-6Al-4V ELI (grade 23): “Extra Low Interstitial” version of grade 5. Higher purity, increased fracture toughness, and improved ductility. The grade for titanium swiss machining medical parts, especially implantable devices where issues in biocompatibility and fatigue life are paramount.

Other alloys (Beta Alloys like Ti-3Al-8V-6Cr-4Mo-4Zr): Very strong, more ductile, and improved cold formability come with even greater difficulty machining. An entirely different approach and discipline is often required, with stiff requirements for tooling and tooling path.

The Engineer’s Toolbox: Best Practices for Swiss Machining Titanium

Success in Swiss machining titanium depends on attention to detail. Here are the principles we live by at Falcon CNC Swiss:

Tooling & Geometry: We use high-quality, uncoated or AlTiN coated micro-grain carbide tools. Sharp cutting edges with positive rake and polished flutes are critical to relieving cutting forces, and aiding chip evacuation. Tool rigidity is vital.

Speed, Feed, and Depth of Cut: The keys here are low surface speed, high feed rate and stable chipload. If we get too slow, we rub and work harden; if we go too fast we build up heat to destructive levels. Moving to the cut’s softer state below the work hardened transition, we maintain relatively brisk cutting with a stable, aggressive feed. The latent heat generated goes into relocating the material, and we consistently get an “easy” chip of predictable dimensions of relatively low hardness.

Chip Control & Evacuation: Our faithful servant, the chip, serves as our primary means to remove heat. We negotiate the parameters to produce a chip that curls into a well-defined “6”or “9”shape that breaks cleanly. Continuous, “bird’s nest”chip formation is suicidal, risking wrap around of the chip on the part and subsequent part damage, or excessive downtime. Our high-pressure coolant systems are set to avoid this, blasting it away instantly!

Fixture & Workholding: We go beyond the guide bushing to custom, hardened tooling and fixtures to ensure fixture stability, as any adopted vibration falls to the part and hence prolongs tool, or compromises surface finish.

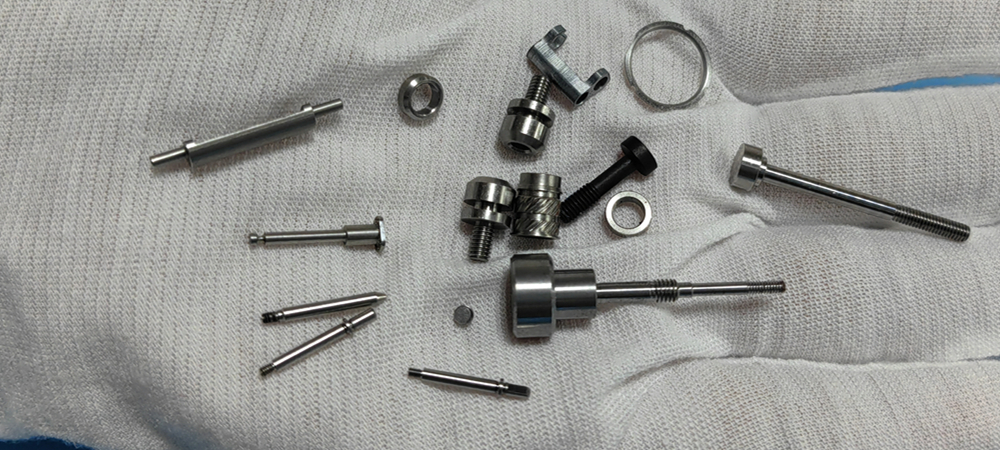

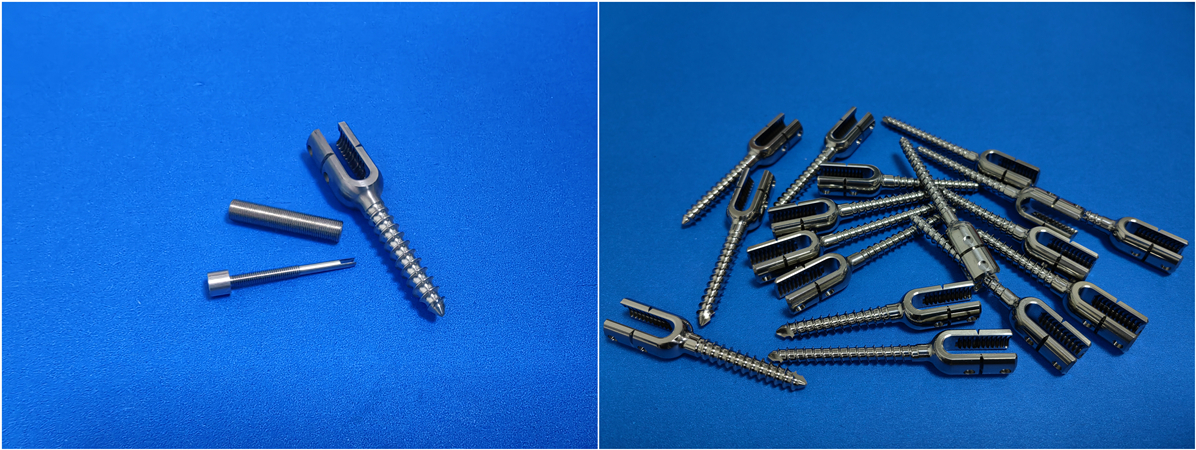

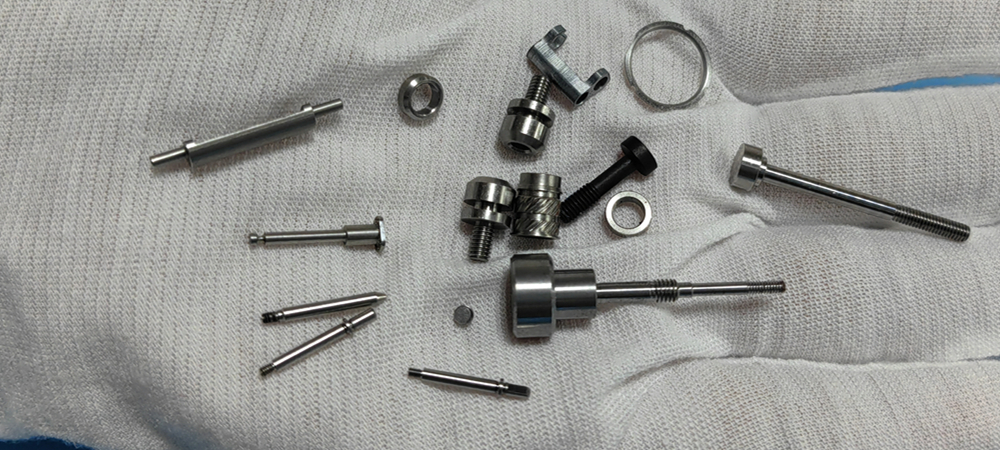

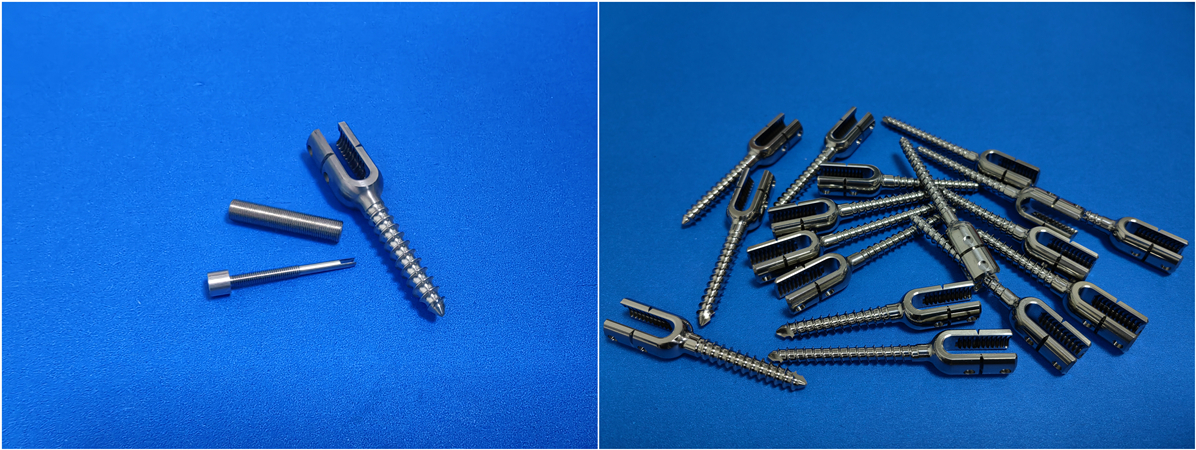

Case in Point: Medical Implant Component

Take this spinal fusion device component: a complex, tiny screw requiring demanding threads and anatomical reach as it is threaded. Machined from Ti-6Al-4V ELI (Grade 5).

Challenge:

Flawless surface for biocompatibility, tolerances of ±0.005mm on certain features, and no possibility of defects such as micro-cracks and residual stress resulting in in-vivo failure.

Our Swiss Machining Solution:

Material Certification: Stock bar, 5-5-5 Ti alloy ASTM F136 compliant, lots traceable.

Process Design: CAM programming using trochoidal milling paths for pockets, resulting in constant tool engagement and heat distribution (and no smeared surface finish). Whirling of screw threads leads to a much stronger as well as more accurate thread.

In-Process Inspection: Parts “probed” between operations to be sure features are in spec before reach final machining. Don’t want parts this expensive going out of spec.

Post-Processing: Parts are deburred, cleaned, and passivated per medical standards for cleanliness.

This level of controlled, expert precision swiss machining titanium is what transforms a design into a reliable, life-enhancing device.

Partnering with the Right Machine Shop: Key Selection Criteria

Given the complexities and costs involved, choosing your partner for Swiss machining titanium china or anywhere else is a strategic decision. Look for:

Transparent Expertise: They should speak confidently about tooling strategies, heat management, and chip formation, not just quote a price.

Specialized Equipment: Ask about machine capability, high-pressure coolant systems (minimum 1000 psi), and spindle technology designed for hard materials.

Quality Infrastructure: In-process probing, post-process CMM inspection, and material certification processes are essential. ISO 9001 and 16949/ISO 13485 certifications are strong indicators of a systematic approach.

Design for Manufacturability (DFM) Input: A true partner will review your drawings early, suggesting slight modifications to radii, wall thicknesses, or tolerances that dramatically improve manufacturability and cost without compromising function.

Conclusion: Turning Your Ideas in Titanium to Reality

Swiss machining titanium is the apex of materials engineering and cutting edge machine tool know how – ergonomic, compliant discipline rather than brute strength is the answer to getting the best from this demanding material.

Is your next project pushing the limits with titanium? Explore our dedicated Swiss machining services to see how we apply this expertise daily. For components where titanium is non-negotiable, delve deeper into our specific capabilities on our custom titanium machining page. Let’s engineer a solution that meets your precision, performance, and reliability goals.