There is zero room for error in the medical industry. From life-saving implants to intricate surgical devices, it has never been more important to achieve exact precision. This is where Swiss machining comes in - providing the accuracy and consistency the medical manufacturers of today require.

At Falcon CNC Swiss, we provide precision machining for medical applications, and we do it better than any manufacturer. Let us count the ways that Swiss machining isn't just keeping up, it's changing standards in medical technology.

1. Why Precision is Essential in Healthcare

Consider the consequences of even the slightest defect in a medical implant. A half-millimeter error in the production of an orthopedic implant screw made of plastic can be the difference between a successful procedure and a patient who must have further surgical intervention. The same goes for cardiovascular devices such as stents as well as medical instruments that have intricate electrical contacts in sensitive monitoring devices. One micron matters.

We can achieve approximately tolerances of ±0.0002 inches with Swiss CNC machining. To say that precision for human life is important is an understatement – precision is critical.

2. Swiss Machining: The New Gold Standard for Medical Production

Why has Swiss machining become the gold standard for manufacturing medical components? Here are some factors that contribute to its use in medical component production:

Micron Accuracy

Medical devices are becoming smaller and more intricate.Swiss lathes are made to attain parts with extraordinarily tight tolerances, and rightfully so for micro components, such as dental implants and neurological devices.

Excellent Surface Finishes

A smooth finish will eliminate contamination and maximize biocompatibility in your applications. Swiss machining will create the surface finish required without a lot of secondary processes.

Consistency Across @ Scale

Manufacturing 100 parts or 100,000 parts using Swiss machining means the same identical part every time - absolutely crucial in compliance for your medical manufacturer.

Complex Geometries with Minimal Effort

When it comes to complicated shapes with tight features that need to be manufactured; get in line - because Swiss machining will dominate - parts like laparoscopic surgical instruments or components for endoscopic devices, etc.-

3. Trending Now: Swiss Machining and the Rise of Minimally Invasive Devices

One of the hottest new topics in the medical world right now is minimally invasive surgery. Patients are looking for less invasive and quicker recoveries and that means "quicker-to-manufacture" smaller more intricate devices.

This is where Swiss machining fits in perfectly, as ultra-precise micro-sized components will allow for the development of instruments used in the new world of high-tech, machine-technologically advantageous devices like robot-assisted surgeries and advanced imaging technologies.

In fact, a 2024 study by Grand View Research reported a 7.9% CAGR through 2030 in minimally invasive surgical devices. Manufacturers who take ownership of precision today will be the leaders of tomorrow.

4. Real-World Applications: Swiss Machined Medical Parts

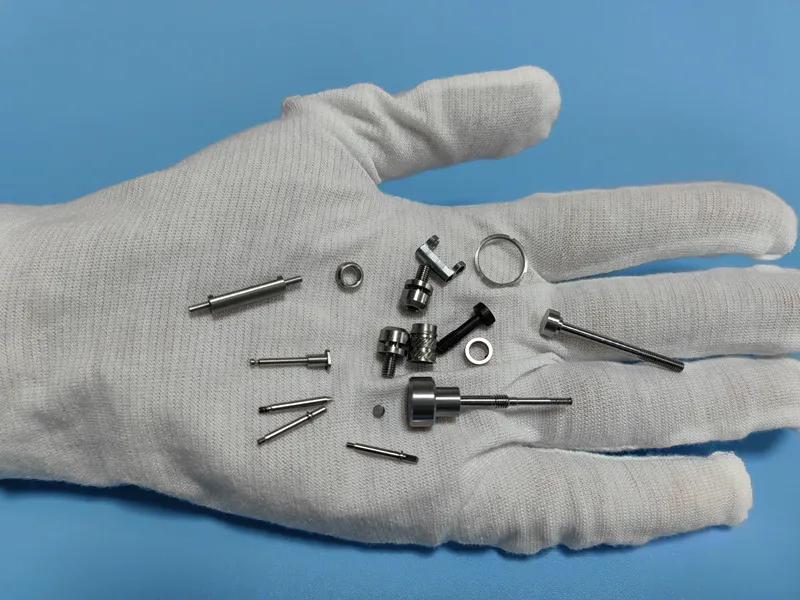

Here are some examples of medical components that would be ideal for Swiss machining:

Orthopedic screws, pins, and plates

Dental implants, drills

Cardiovascular implants (stents, valves)

Micro components (hearing aids, cochlear implants)

Surgical tool shafts, biopsy tools

Precision parts (diagnostic imaging machines)

At Falcon CNC Swiss we've had the honour of supplying precision components to OEMs supplying life-critical innovations, demonstrating the required social responsibility, from prosthetics of the next generation to neurological stimulation.

5. Choosing the Right Partner: Falcon CNC Swiss

Medical manufacturing is much more than a part — it involves trust. Trust that your supplier understands and adheres to ISO 13485 standards, FDA guidelines, all while understanding the critical importance of all / every component.

Here is what you can expect from Falcon CNC Swiss:

State-of-the-art Swiss CNC machining centres

Experience in the handling of medical-grade materials (Titanium, PEEK, stainless steel, and cobalt-chrome)

End-to-end quality assurance, with full traceability

Short lead times & consistency to meet those urgent uncertainties in your projects

Our goal is to be the partner you turn to when it matters most — in medical devices there are no second chances.

6. In Conclusion: Swiss Machining + Medical Innovation = The Future

From life-critical implants to precision diagnostic tools and systems powering the next wave of innovation, Swiss machining has positioned itself as the industry’s starting point of tomorrow. As technologies develop and demands for precision become sharper and longer, a precision expert like Falcon CNC Swiss will provide you with a competitive advantage through quality and reliable service.

Are you seeking medical precision machining you can really depend on? Let’s make it happen.

�� Contact Falcon CNC Swiss today to discuss your next project.