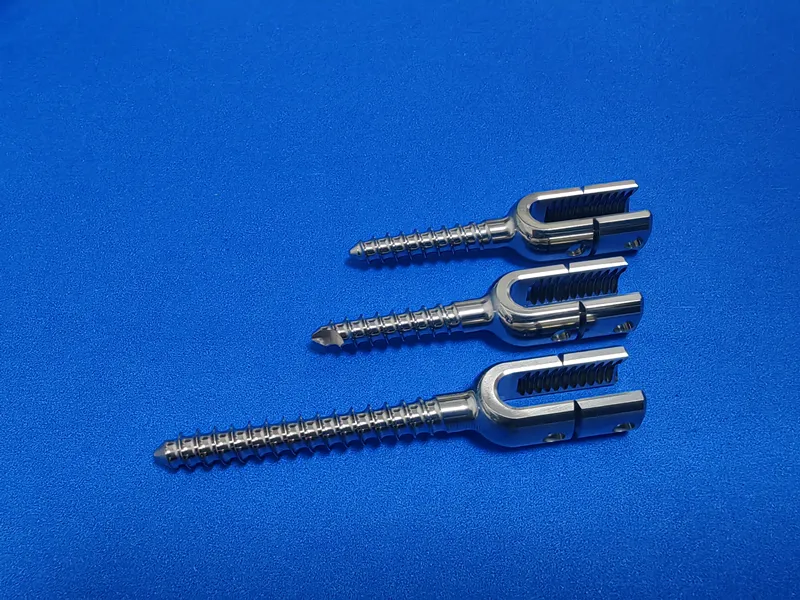

Choosing the right dowel pin manufacturer is critical for applications that require accurate alignment, repeatability, and long-term mechanical stability. Dowel pins are widely used across automotive,...

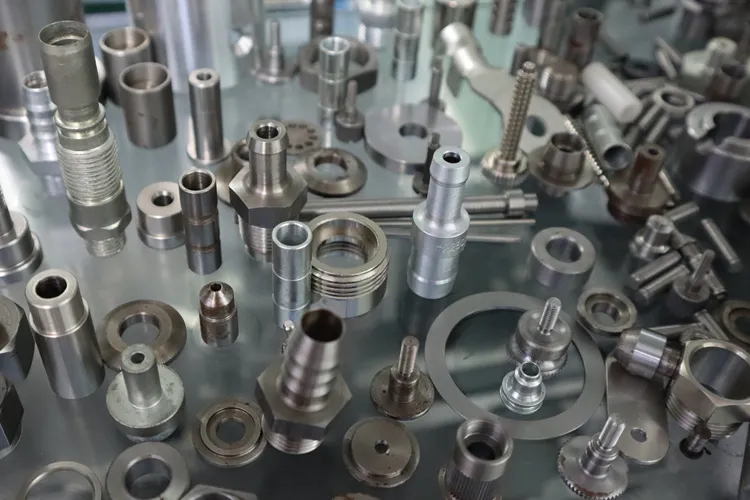

- High Volume CNC Machining

- 5 Axis Machining Service

- CNC Milling Service

- CNC Turning Service

- Swiss Machining Hub

- CNC Contract Manufacturing

- Machined Humanoid Robot Parts

- CNC Machined Impellers

- CNC Machined Enclosures

- CNC Machined Heatsinks

- CNC Machined Manifold Blocks

- CNC Machined Brackets

- CNC Mahined Spline Shafts

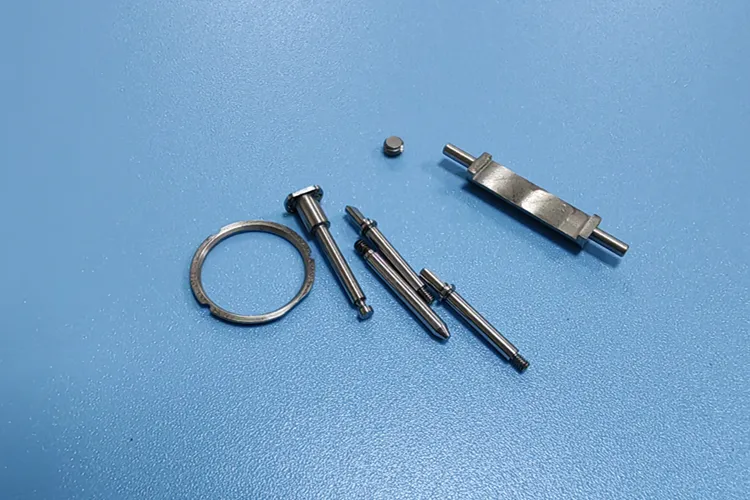

- CNC Machined Mold Pins

- Bolts & Nuts

- Inserts & Bushings

- Pins & Shafts

- Connectors & Fittings

- Valves and Couplings

- Electrical Contacts & Screws

Search

What are you looking for?