Why use Falcon CNC Swiss for Custom Fasteners and Titanium Bolts?

Falcon CNC Swiss offers custom fasteners and titanium bolts utilizing advanced CNC Swiss machining, combined with experience. We are a quality, precision, and customer service-focused company, and have become a preferred source for fasteners and titanium bolts within aerospace, medical, automotive, and industrial markets.

Our Advantages:

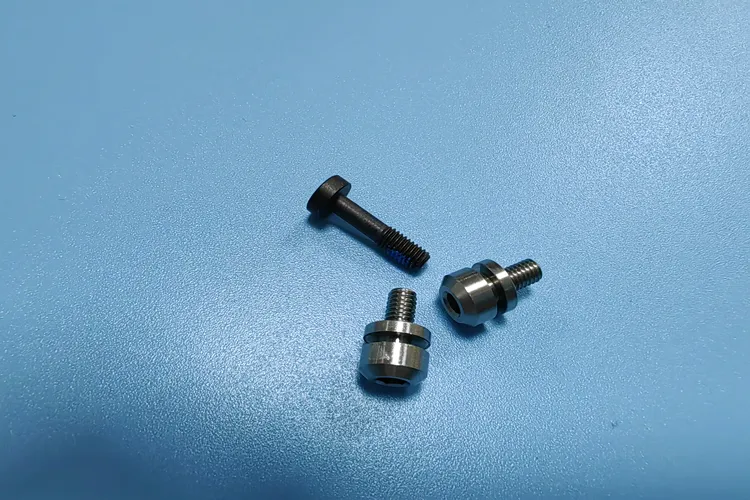

Precision Manufacturing: As tight as ± 0.003 mm tolerances provide precise fit and function across many applications.

Material Knowledge: Stainless steels all the way to aerospace grade titanium. We can work with any material you need.

Total Quality: We have inspection processes that guarantee identical and reliable product performance every time.

Flexibility in Production: Single units of prototypes or thousands of parts, we provide volume and timing options for every situation.

Surface Finishing: We offer anodizing, plating, passivation, and polishing every option for performance and appearance.

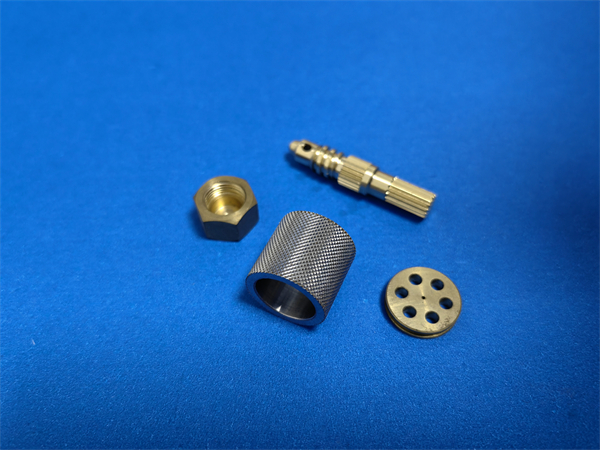

We offer a whole range of CNC fasteners to support the various requirements of our customers around the globe. From standard parts to high-performance materials, such as titanium fasteners, everything we produce is manufactured to exact specifications and inspected to rigorous ISO-certified quality standards.

We produce robust stainless steel nuts prized for their high strength and outstanding corrosion resistance. We work with various grades including 304, 316, and 316L to match the specific chemical, marine, or sanitary exposure requirements of your application. Our process includes achieving excellent surface finishes and passivation to maximize the innate rust-resistant properties of the stainless steel. These attributes are vital for marine hardware, chemical processing equipment, food & beverage machinery (where cleanability and sanitation are paramount), and architectural applications demanding longevity and aesthetic durability.

| Category | Material Options | Applications |

| Bolts | Stainless steel, carbon steel, titanium, aluminum | Machinery, automotive, aerospace |

| Nuts | Stainless steel, carbon steel, titanium, aluminum | Mechanical assemblies, industrial equipment |

| Screws | Stainless steel, carbon steel, titanium, aluminum | Electronics, structural fastening |

| Washers | Stainless steel, carbon steel, titanium, aluminum | Load distribution, vibration resistance |

| Studs | Stainless steel, carbon steel, titanium | High-strength joints, construction |

Titanium Bolts | Grade 5, Grade 2 titanium | Aerospace, marine, high-performance machinery |

| Titanium Nuts | Grade 5, Grade 2 titanium | Aerospace, marine, corrosion-resistant projects |

From medical-grade titanium bolts to corrosion-resistant stainless steel nuts, our Swiss-machined fasteners meet the tightest tolerances (±0.0002").

✅ Free DFM Analysis

✅ ISO 13485/9001 Certified

✅ No MOQ Prototyping

We excel at producing fully custom and engineered fasteners where standard solutions are inadequate. This encompasses parts with complex geometries, integrated features (like combined bolt-washer assemblies), fasteners with proprietary drive systems, or those specified from specialty or hard-to-machine materials. Our process begins with a collaborative Design for Manufacturability (DFM) review, where our engineers partner with you to optimize the design for performance, cost-effectiveness, and manufacturing reliability. These engineered-to-order solutions are pivotal in prototyping breakthrough products, advanced robotics, semiconductor manufacturing equipment, and defense systems.

Engineer Your Success with Precision Fasteners

Have a specific challenge that requires a custom fastener solution? Partner with our engineering team to turn your design into a reliable, high-performance component. Submit your drawings and requirements today to receive a comprehensive quote and expert DFM analysis. Ensure the integrity and reliability of your next project with fasteners built to the highest standards of precision.

Contact us today for a fast quote, and see why clients from around the globe trust our Swiss machined bolts and nuts.

What Our Customer Say:

"Falcon CNC Swiss delivered 50,000 titanium bone screws with M1.2 threads for our spinal implant line. Their ISO 13485 compliance and full material traceability accelerated our FDA submission by 6 weeks."

– Dr. Emily P, Lead Engineer

A OEM Medical

FAQ

Q: What materials are available for custom bolts?

A: Titanium (Grade 5/23), 316L stainless steel, PEEK, and cobalt chrome.

Q: Can you machine micro-threads (e.g., M0.6)?

A: Yes. Our Swiss lathes produce threads as small as M0.6 with ±0.0001" pitch accuracy.

Q: Do you offer passivation for stainless steel fasteners?

A: Yes. In-house passivation ensures ASTM A967 compliance for corrosion resistance.