Grinding and polishing

Screw machined products may undergo grinding and polishing operations to improve their surface finish and remove any burrs or sharp edges.

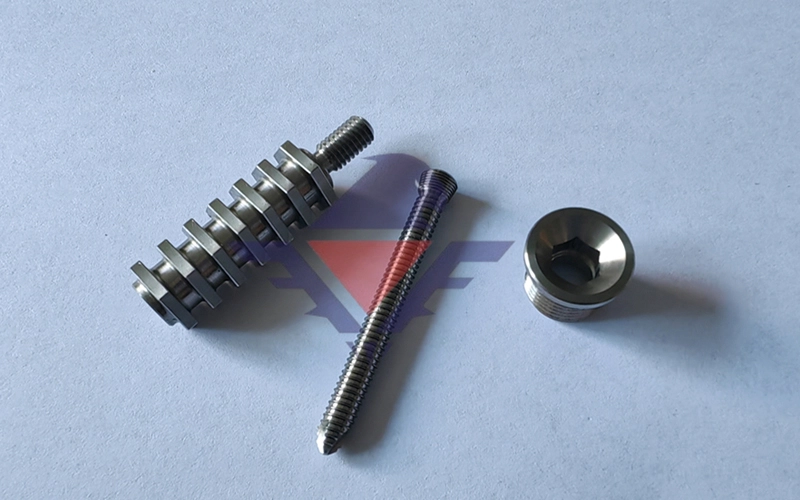

Precision screw machine products are high-volume, dimensionally critical components manufactured on automatic lathes or CNC Swiss-type machines. These parts are essential in applications where repeatable accuracy, complex geometries, and flawless finishes are non-negotiable.

Screw machine products are precision-turned components manufactured on automated lathes or advanced CNC Swiss-type machines. These parts are characterized by their cylindrical form, high dimensional accuracy, and are typically produced in large volumes. Common examples include precision pins, shafts, spacers, fittings, and threaded inserts. Due to their repeatability and reliability, they are foundational components in industries like electronics, medical devices, automotive systems, and aerospace assemblies.

Precision screw machine products frequently are manufactured with sophisticated Swiss-type and CNC equipment to provide micro-level tolerances, features, and surfaces. Compared to standard parts, precision screw machine products allow tighter tolerances, improved concentricity, and greater reliability in heavy-use applications. Where simple turned parts will do, producers may well opt to go that route. With demanding applications in the medical, aerospace, electronics, and other fields, however, shops prefer to produce complicated parts on a Swiss screw machine, where the accuracy, and ability to withstand long-term use, create stability and enhance performance.

We manufacture a wide variety of screw machine parts and components that have been engineered for performance and durability and exhibit reliability in demanding environments. Our advanced machining capabilities encompass a wide range of materials, including, but not limited to; stainless steel, brass, aluminum, and titanium.

Falcon Swiss machines parts from a wide array of materials to meet your specific functional and environmental requirements. Our expertise ensures optimal machinability and part integrity.

Brass Screw Machine Part & Copper Alloys: Excellent for electrical components, connectors, and decorative fittings due to their conductivity and corrosion resistance.

Stainless Steels (303, 304, 316, 17-4 PH): The standard for corrosion resistance and strength in medical, marine, and food-grade applications.

Aluminum (6061, 7075): Ideal for lightweight, high-strength parts in aerospace and automotive applications.

Engineering Plastics (PEEK, Acetal, UHMW): Used for insulating, low-friction, or chemically resistant components.

Titanium & Exotic Alloys: For the most demanding applications requiring the best strength-to-weight ratios and biocompatibility.

Are you in need of custom screw machine products? Our team of engineers, designers, and manufacturers can produce custom screw machine components specific to your design and functional requirements. With the aid of our advanced CAD/CAM programming and multi-axis machining, we can produce parts containing complex features, multiple operations, and tight schedule delivery. We work closely with our customers engineers to ensure functional properties such as; appropriate material selection, surface finish, and tolerance for a reliable part fit for your application.

Selecting the right manufacturing partner is critical. Here’s why industry leaders trust Falcon Swiss screw machine shop for their precision component needs or learn more about our Swiss machining services:

Our core competency is producing complex, high-tolerance Swiss screw parts that other shops find challenging.

We maintain control from raw material to finished part, with in-process inspections and final QC using CMMs and optical comparators to ensure every batch meets print.

Our automated cells and lean processes are optimized for efficient, consistent, and cost-effective screw machine products manufacturing, from prototypes to millions of parts.

We understand the regulatory and performance demands of medical device, aerospace, automotive, and electronics manufacturing, helping you navigate from design to delivery.

Our screw machine services yield a broad spectrum of applications, from standard parts to quality screw machine products. For whatever you need our help with, we add capabilities, materials, and quality assurance in a way that guarantees the finished part, be it brass or stainless steel, is useful in the most demanding of applications.

Machining: Advanced CNC and Swiss screw machining produces all manner of components: from screw machine products to Swiss screw machine products of high precision.

Finishing: Grinding and polishing delivers parts with good surface finish and dimension retention and better part life.

Customization: From brass screw machine products to custom screw machine products, our manufacturing process is made-to-order as far as practical.

Here we show how our screw machine services serve key industries, against a background of examples of precision components we manufacture:

| Industry | Application Examples |

| Automotive | Precision bushings, threaded fasteners, and shafts for engine or drivetrain systems. |

| Medical Devices | Surgical pins, orthopedic implants, and micro-fittings with exact tolerances. |

| Aerospace & Defense | High-strength connectors, custom fasteners, and lightweight components essential for critical missions. |

| Electronics | Miniature shafts, pins, and contact components used in connectors and assemblies. |

| Industrial Equipment | Heavy-duty machine parts, couplings, and hardware for high-load applications. |

| Renewable Energy | Custom components for solar mounts, wind turbine hardware, and energy storage systems. |

As a leading screw machine products company, Falcon CNC Swiss provides precision-engineered parts with today's manufacturing technology and stringent quality controls. We are ISO-certified and rely on for screw machine parts, Swiss screw machine components, and custom-machined items for the industry. Keeping within tolerances and specifications is our forte.

State-of-the-art Swiss CNC equipment - Best capable of manufacturing your complex high-tolerance parts.

Material expertise - We work with stainless steels, brass, aluminum, titanium, and plastics.

Scalable production - We can manufacture anything from prototypes to production.

Quality Assurance - With our quality management system we have CMM inspections, tolerances, and surface finishes controlled.

Delivery on Time, Anywhere - We have fast turnaround times and great logistics.

If you're looking for screw machine services, custom components, or a reliable screw machine shop, we are ready to partner with you on your project. Let Falcon CNC Swiss handle all your screw machine products and Swiss screw parts. Experience the level of precision, quality, and customer service only Falcon CNC Swiss can provide.

Contact Us Today for Review on your automatic screw machine products project!

Screw machines are specialized lathes that are designed to produce large volumes of precision parts quickly and efficiently. They are typically used to produce small to medium-sized parts, such as screws, bolts, fittings, and other components that require high precision and accuracy.

Screw machines use a rotating tool to remove material from a workpiece, shaping it into the desired form. This process is highly automated, with the machine feeding in raw material and producing finished parts at a high rate of speed. The result is a highly precise and consistent product that is ideal for use in a wide range of industries, from automotive and aerospace to medical and electronics.

There are several types of machines used in screw manufacturing to produce high-precision parts in large volumes. The most common types of machines used in screw manufacturing include: Automatic screw machines, CNC screw machines, Swiss screw machines, Rotary transfer machines, Multi-spindle machines.

The screw is one of the six simple machines, which are fundamental mechanical devices used to make work easier. Here are just a few examples of screw simple machines, which are used in a wide range of applications in various industries. Some examples of screw simple machines include:

Screwdriver: A screwdriver is a handheld tool that is used to turn screws by applying torque to the handle. It consists of a long, thin shaft with a flat or Phillips head at one end.

Jar lid: A jar lid is an example of a simple machine that uses a screw to secure the lid of the jar. The threads on the jar and lid allow the screw to be turned, securing the lid in place.

Clamp: A clamp is a device used to secure two objects together using a threaded screw. The screw is turned to apply pressure and hold the objects in place.

Bolt: A bolt is a threaded fastener that is used to secure two or more objects together. The threads on the bolt allow it to be screwed into a threaded hole or nut.