Why Choose Falcon CNC Swiss for 5-Axis CNC Machining?

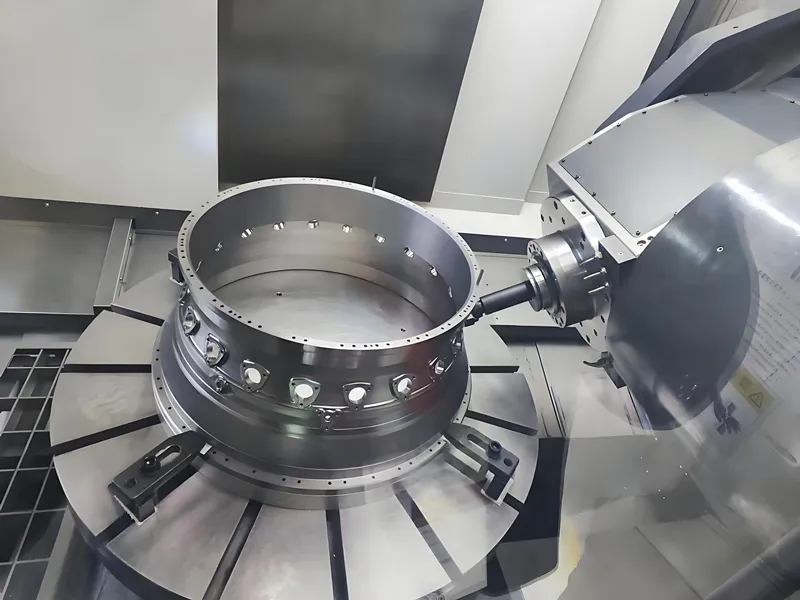

Trust our 5 Axis Machine Shop for precision complex parts. We deliver superior accuracy, efficiency, and quality from prototype to production. Partner with experts in advanced 5-axis CNC machining solutions.

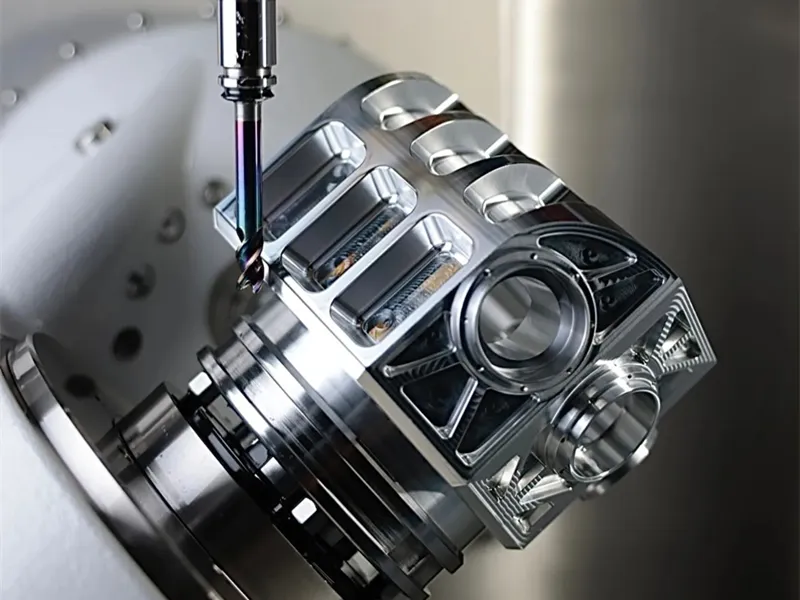

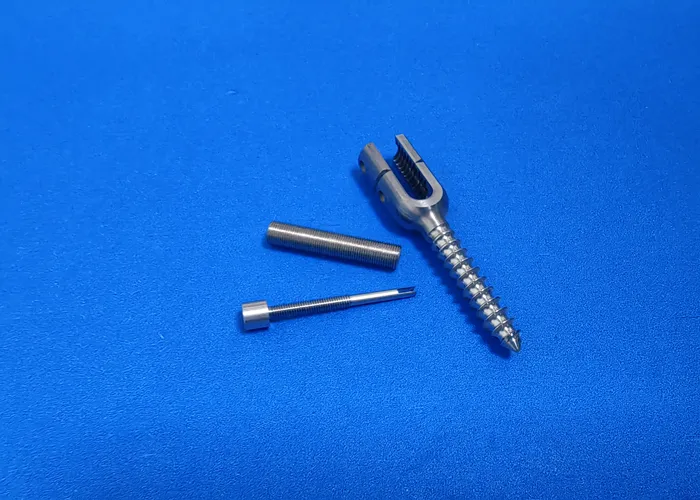

Expertise in Complicated Parts: We love a challenge! Bring us your most complex precision machining project.

Experience: Our engineers provide Design for Manufacturability (DFM) recommendations so you can best prepare your part for cost and efficiency.

Quality Assurance: Each part is stringently measured to specifications with a variety of CMM and metrology equipment to ensure adherence to print specifications.

Supporting Every Project Realization: We support your project from low-volume prototyping to high-volume production runs.

Get a Free 5-Axis Machining Quote

When you’re ready to utilize our 5 axis CNC service for your complex part machining projects, select Falcon CNC Swiss, the 5-axis machine shop designed for complex and precision machining. Send us your CAD files (STEP, IGES) and drawing for a fast, accurate quote and DFM recommendations.

Want to speak to an engineer? Contact Our Machining Engineers for 5-Axis Machining Quote today!

FAQ for 5 axis CNC service

Q: What file formats are required for a 5-axis machining quote?

A: We request CAD files in 3D (STEP, IGES) and a 2D PDF drawing with dimensions and tolerances.

Q: What are advantages of 5-axis versus 3-axis machining?

A: Advantages include being able to machine very complex geometries with setup, improved accuracy, improved surface finish and overall less machining time for each part altogether.

Q: Can you handle low and high volume for complex machining?

A: Yes 100%! Our 5-axis CNC service can accommodate each phase, from prototype, low or high volume for complex parts production.

Q: What lead times can I expect for a 5-axis project?

A: Lead times depend on complexities of parts and volume. We pride ourselves on quick quote and prototype response. Please reach out to us with your details for lead time.