Why Choose Falcon for Your Enclosure Manufacturer?

- Expert DFM Analysis: Our Engineers will analyze your design for your custom enclosures and suggest improvements to reduce cost and enhance manufacturability, without sacrificing function.

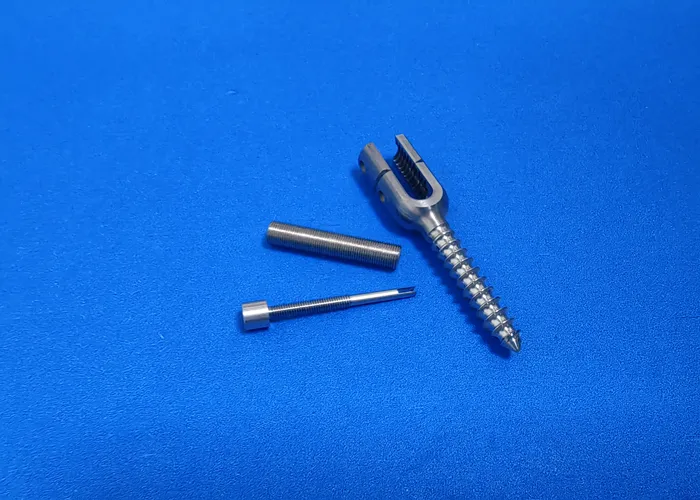

- Scalable Production: We are set-up for the best high volume manufacturing. Our automated cells and high volume screw machining production capability allows us to efficiently scale production based on your requirement from thousands to millions of units.

- Vertical Integration: We have a full suite of surface finishing processes like anodizing, powder coating, bead blasting, and silk screening, delivering a complete source for your machined enclosure requirements.

- Uncompromising Quality: Our comprehensive quality management system driven by SPC, and CMM inspection, ensures everything that we manufacture and ship meets your precise specifications and the highest quality standards.

Ready to Get a Quote for Your Custom Enclosure Project?[Request a Free Quote & DFM Analysis]

Frequently Asked Questions (FAQ)

Q: What are the advantages of a CNC machined enclosure rather than a fabricated one?

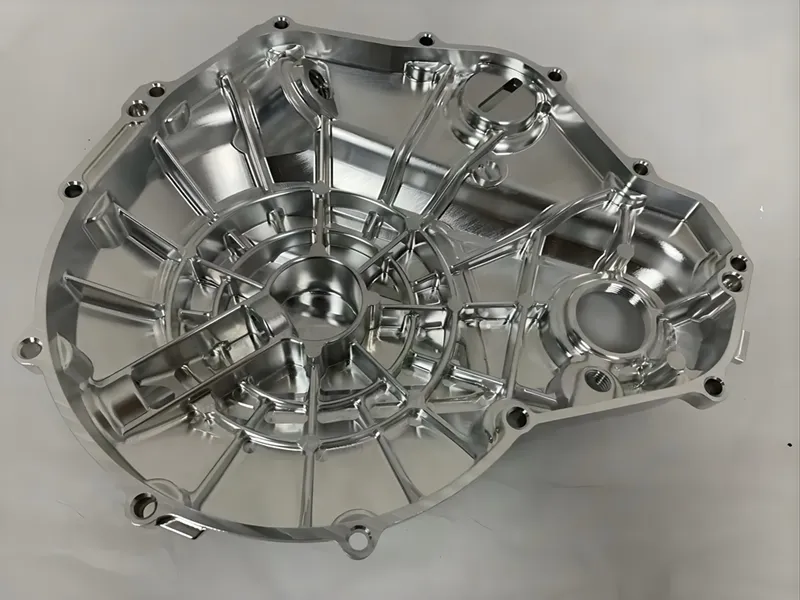

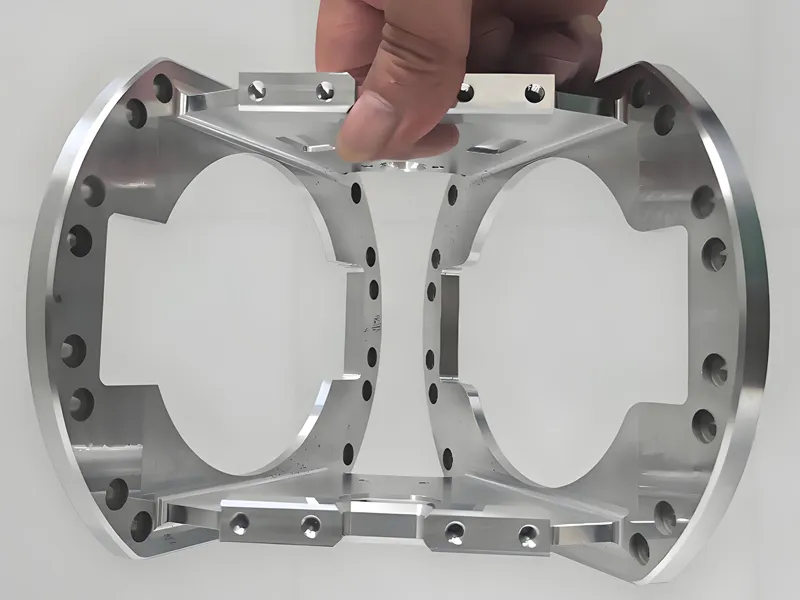

A: CNC machined enclosure will have superior functional precision, strength and design flexibility. It is milled from a solid block of material, and there will be no weak points made by welding or bending. Additionally, something that is CNC machined is completely automated - easily achieving the repeatability an order of any quantity requires.

Q: Do you accept high-volume orders for custom electronic enclosures?

A: Yes. High-volume CNC machining is our strong suit. Our automated production lines and scalable CNC production processes are developed for efficient large batch CNC production of custom electronic enclosures and other housings.

Q: Do you provide finishing and assembly?

A: Yes, we will manage that for you as well! We machine your custom enclosure, add surface finishes, and do light assembly all in-house, which simplifies your supply chain and quality control.