Why Falcon Should Be Your Heatsink Supplier?

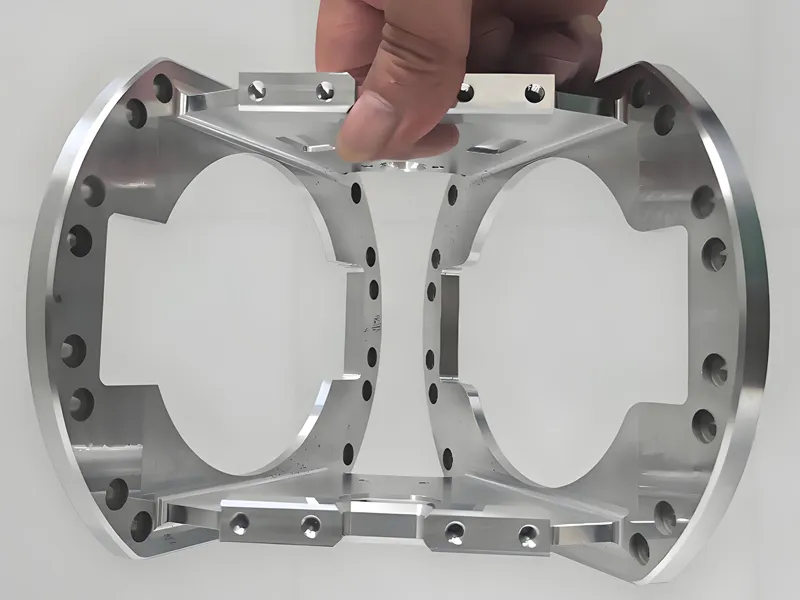

Thermal Engineering Expertise: We understand heat transfer principles and provide custom heatsink design optimization for optimal performance

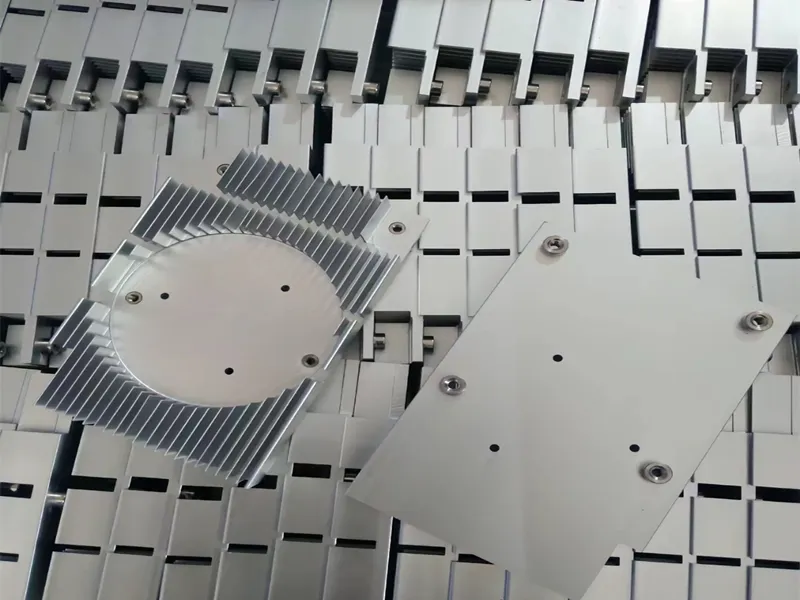

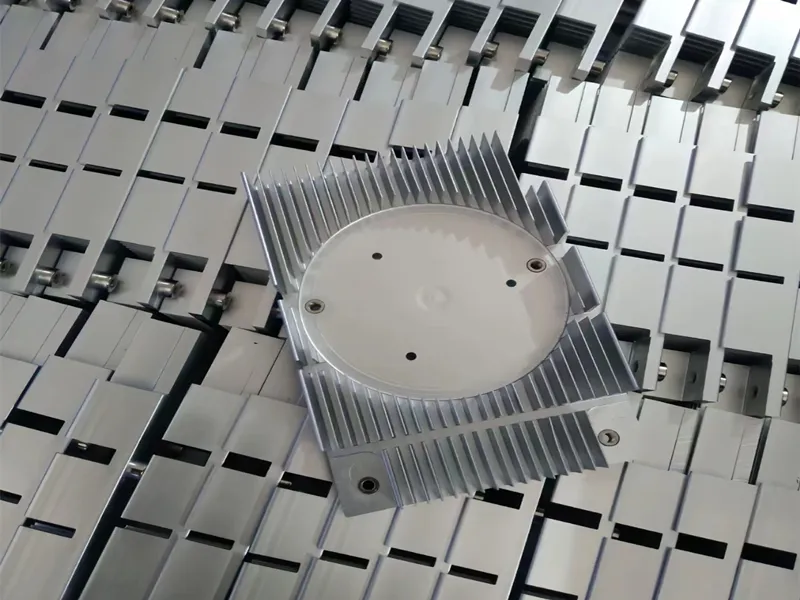

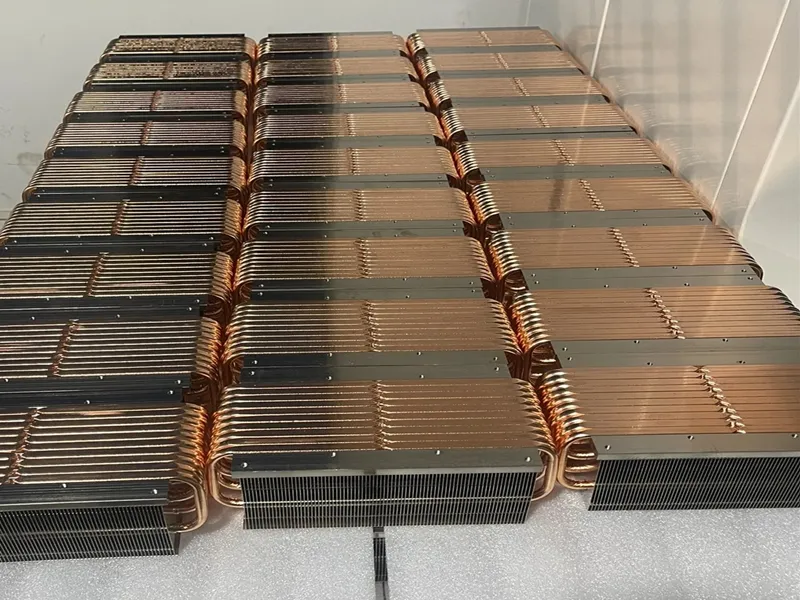

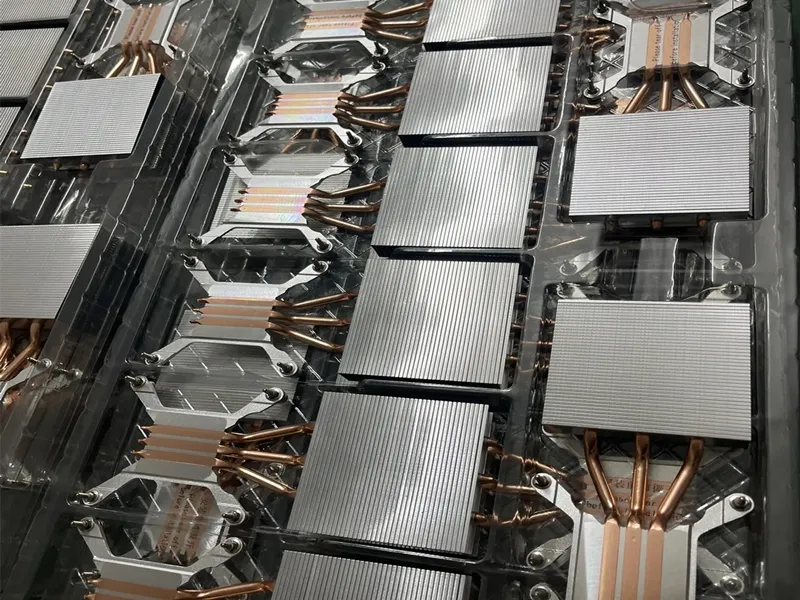

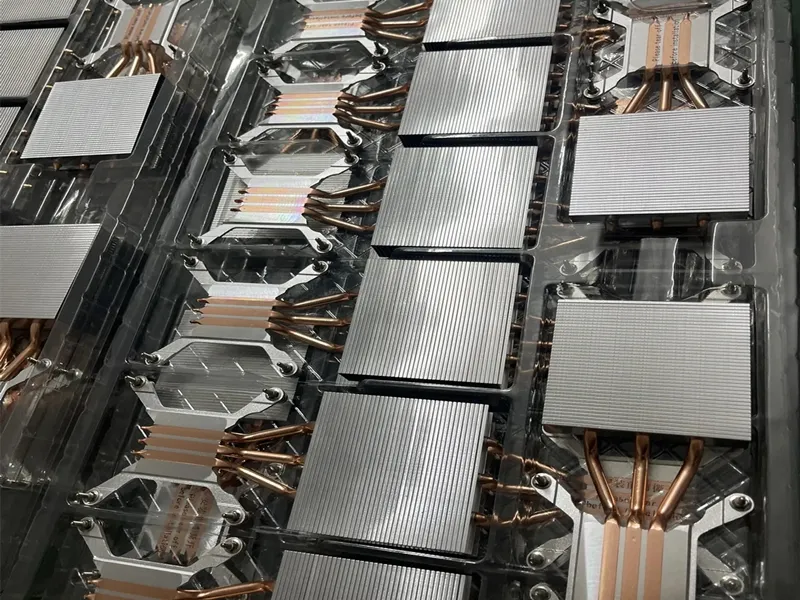

High Volume Production: Automated manufacturing cells for high volume heatsink production with consistent quality

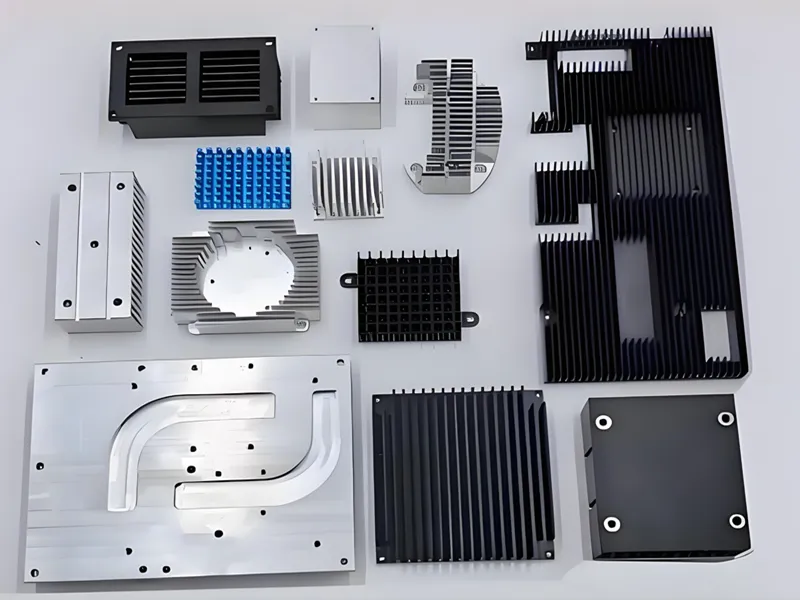

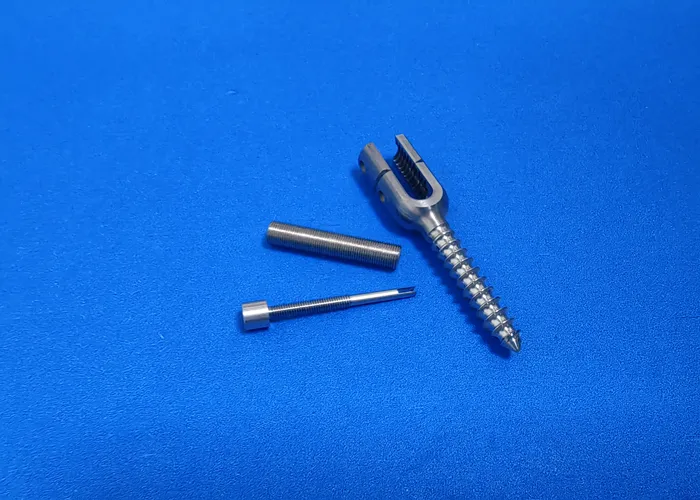

Full Manufacturing Services: Whether it be material selection, CAD, precision machining, die casting and extrusiton solutions, deburring, and finishing (such as anodizing for aluminum and passivation for copper)

Quality Assurance: Using statistical process control (SPC) we are able to ensure dimensional accuracy as well as consistency in thermal performance across production runs.

Design for Manufacturability: Our engineers offer free DFM analysis to optimize all aspects of your heatsink design for performance and cost-effectiveness.

As your aluminum heatsink suppliers, we can provide you with solutions that consider thermal performance, weight and cost to meet your application's requirements.

Ready To Optimize Your Thermal Management Solution? [Contact Our Thermal Engineering Team]

FAQ

Q: What is the minimum fin thickness that you can do for aluminum heatsinks?

A: We can routinely machine fin thickness down to 0.5mm, at aspect ratios up to 15:1 for aluminum heatsinks, thanks to our high-speed machining capabilities and tooling specialization.

Q: Can you do large volume orders for consumer electronics applications?

A: Absolutely, doing high volume heatsink production is the core of our business! Our automated manufacturing cells allow us to easily scale to production constraints of millions of units, while maintaining the same quality.

Q: Do you conduct a thermal performance testing or simulation?

A: Our focus is on precision and manufacturing, but we can provide you with a list of trusted partners that can perform thermal simulation and testing to validate your performance. We also provide material certifications and complete dimensional inspection reports.

Q: What are the available surface treatments of heatsinks?

A: For aluminum heatsinks, we offer anodizing (clear and colored) to improve corrosion resistance and surface hardness. For copper heatsinks, we provide passivation or other anti-tarnish treatment to defer oxidation.