Quality and Accuracy You Can Rely On

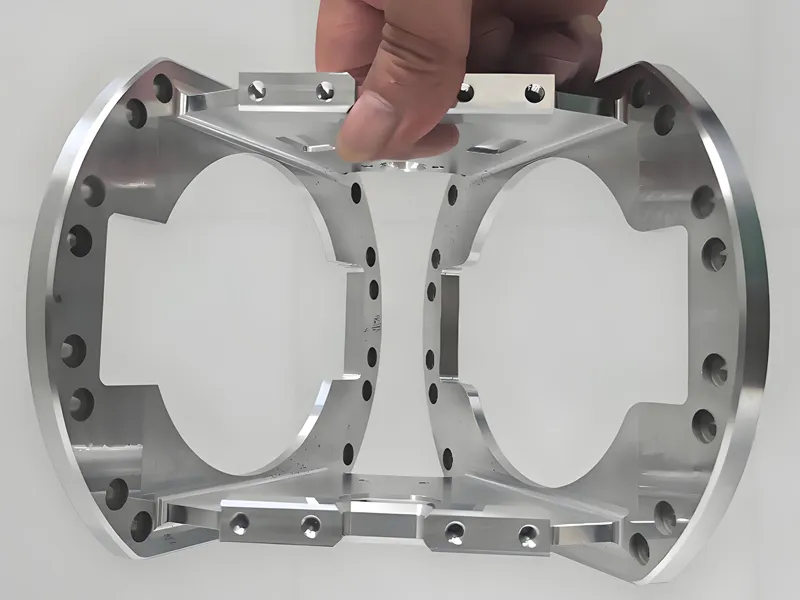

CAD/CAM machining provides reliable speed and precision of impeller machining.

High precision CNC machining services produce precision balance and performance.

Dynamic balancing is also done on turbine impellers and turbo impellers.

Surface finishing, coatings and polishing provide durability and efficiency.

If you’re looking for CNC machined impellers you can depend on, Falcon CNC Swiss can provide the impellers for you. Whether it’s titanium turbo impellers, aluminum blower impellers or precision turbine impeller machining, we provide precise quality parts and speedy service. Contact us today for a quote on custom impeller machining.

FAQ – Precision CNC Machined Impellers Manufacturing

Q1. What does CNC machined impeller manufacturing mean, and why is that important?

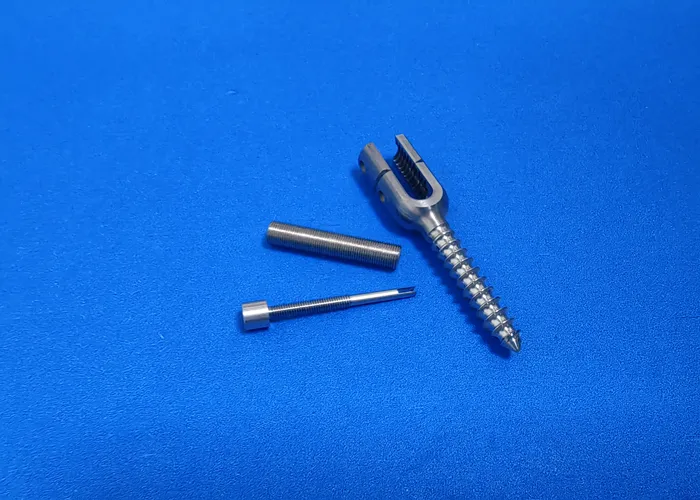

A. CNC machined impellers are produced using advanced 5-axis CNC machining processes to produce exact geometry, strength, and surface finish. These attributes are important for the function and dependability characteristics like turbo impeller machining, closed impeller machining, and turbine impeller blade applications.

Q2. What materials are good candidates for CNC impeller machining?

A. Popular materials are titanium impellers, aluminum impellers, stainless steels, and aluminum brass. Titanium impeller machining is suitable for high-performance pump and aerospace applictions. Aluminum impellers are common candidates for automotive turbo impellers, and blower impellers.

Q3. How does 5-axis CNC machining impacts the ability to create complex impeller designs like closed impellers and turbine impeller shafts?

A. Yes. With 5-axis CNC impeller machining, closures, turbine impeller shafts, and multi-blade turbo impellers will have remarkable accuracy and surface finish.

Q4. What industries demand CNC machined impellers, and why?

A. They are used in aerospace applications (titanium turbine impellers), automotive applications (turbo impeller machining), energy applications (turbine impeller pumps), and industrial applications (aluminum blower impellers, pump impellers).

Q5. What are the advantages of titanium impeller machining over aluminum impeller machining?

A. Titanium impellers have strength, heat resistance, and corrosion resistance advantages, which work well for aerospace turbines, and high-performance pump impellers. Aluminum impellers are lightweight and cost effective, which work well for blower and automotive turbo impellers.