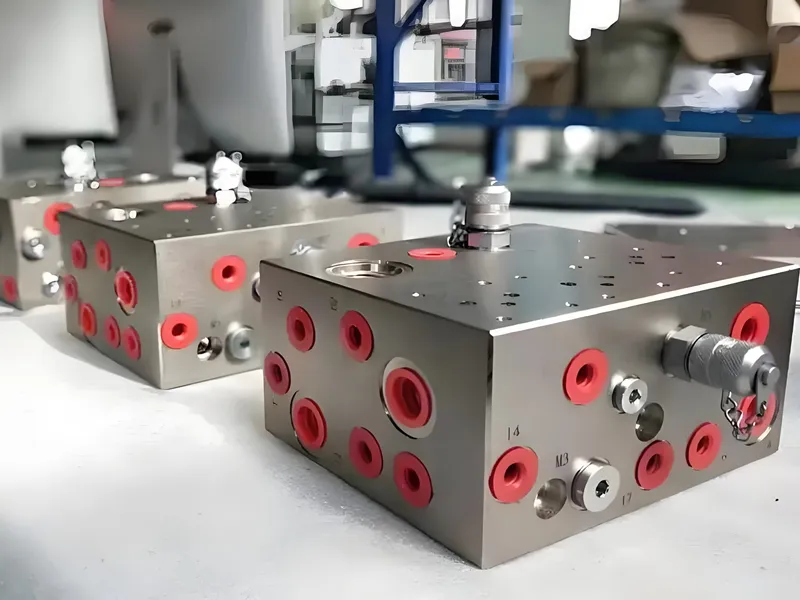

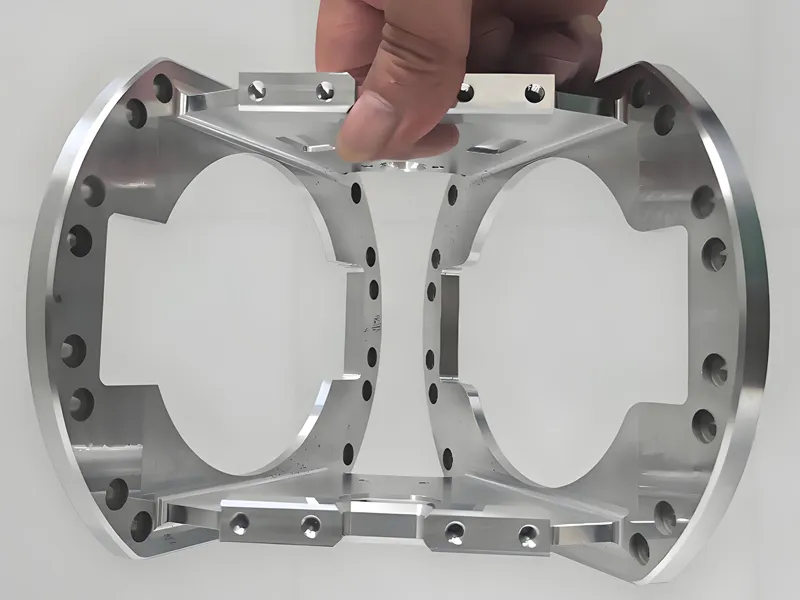

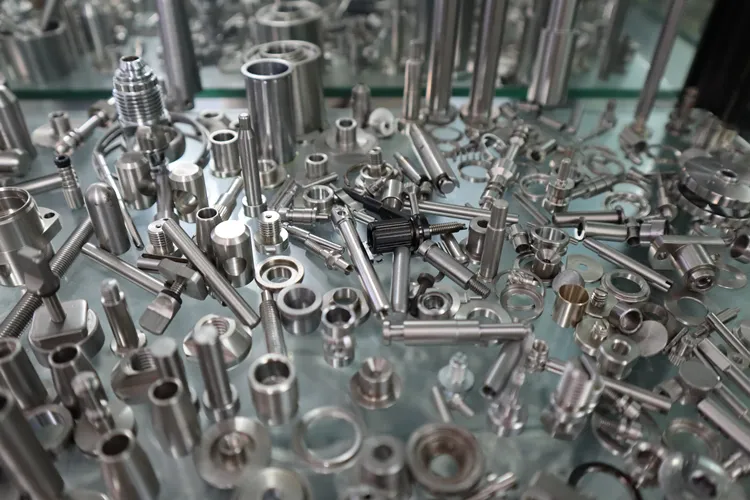

Choosing the right design and material for your hydraulic manifold is essential for reliable, high-performance, and cost-effective systems. At Falcon CNC Swiss, we are trusted hydraulic manifold manufacturers, combining engineering expertise with advanced CNC manifold machining capabilities, including precision milling and turning, to produce custom valve manifolds that meet your specific requirements for pressure, media, and operating environments.

We provide solutions for both prototypes and high-volume production runs, ensuring consistent quality, repeatability, and excellent value. Our experience with various materials and manifold types allows us to deliver components that perform reliably across industrial, automotive, and energy applications.

Below is a guide outlining our standard offerings for the most common manifold types:

| Manifold Type | Primary Materials | Key Properties | Pressure Rating | Typical Applications |

| Hydraulic Manifold Blocks | 4140 Alloy Steel, 1018 Carbon Steel | High strength, excellent fatigue resistance, good machinability | Up to 5000 PSI (345 bar) | Heavy equipment, injection molding machines, press systems, industrial machinery |

| Pneumatic Manifold Blocks | Aluminum 6061-T6, Brass C36000 | Lightweight, good corrosion resistance, excellent machinability, cost-effective | Up to 250 PSI (17 bar) | Factory automation, robotics, air control systems, packaging machinery |

| Water/Coolant Manifolds | 316 Stainless Steel, Aluminum 6061-T6 | Excellent corrosion resistance, cleanability, resistant to scaling and bacteria | Up to 500 PSI (34 bar) | Laser cutters, CNC machining centers, cooling systems, process water lines |

| Fuel & Oil Manifolds | 304 Stainless Steel, 316 Stainless Steel | Resists degradation from hydrocarbons, maintains integrity with aggressive fluids | Up to 1000 PSI (69 bar) | Engine test stands, fuel dispensing systems, lubrication systems, processing equipment |

| High-Purity & Chemical Manifolds | 316L Stainless Steel, PEEK (Plastic) | Ultra-high corrosion resistance, non-reactive, easy to sterilize and clean | Varies by design | Semiconductor processing, pharmaceutical manufacturing, chemical injection, food & beverage |

Manifold Blocks Material Choice Guidelines

For Maximum Strength and Durability: 4140 Alloy Steel is the most common industry standard for hydraulic manifold blocks that undergo high cyclic loading and pressure. It can be treated to increase surface hardness.

For Best Corrosion Resistance and Cleanability: 316 Stainless Steel manifold is second to none for applications that involve water/chemicals or where a purity definition must be met, for example by AWWA standards, such as in stainless water manifold systems.

For Light Weight and Cost Effective Solution: Aluminum 6061-T6 is best for pneumatic manifold blocks and to lower-pressured hydraulic systems, it gives the best strength-to-weight ratio.

For Specialised Applications: Engineering plastics, for example, PEEK provide outstanding chemical resistance and insulation properties as well as meet very specific fluid handling challenges.

Don't know which material is right for your application? Our engineers perform a free Design for Manufacturability (DFM) analysis and advise on your optimal choice of materials and design to meet performance and longevity as well as manufacturability for high-volume applications.

[Contact our engineers] for free design consultation on your details and specifications for your manifold requirement.