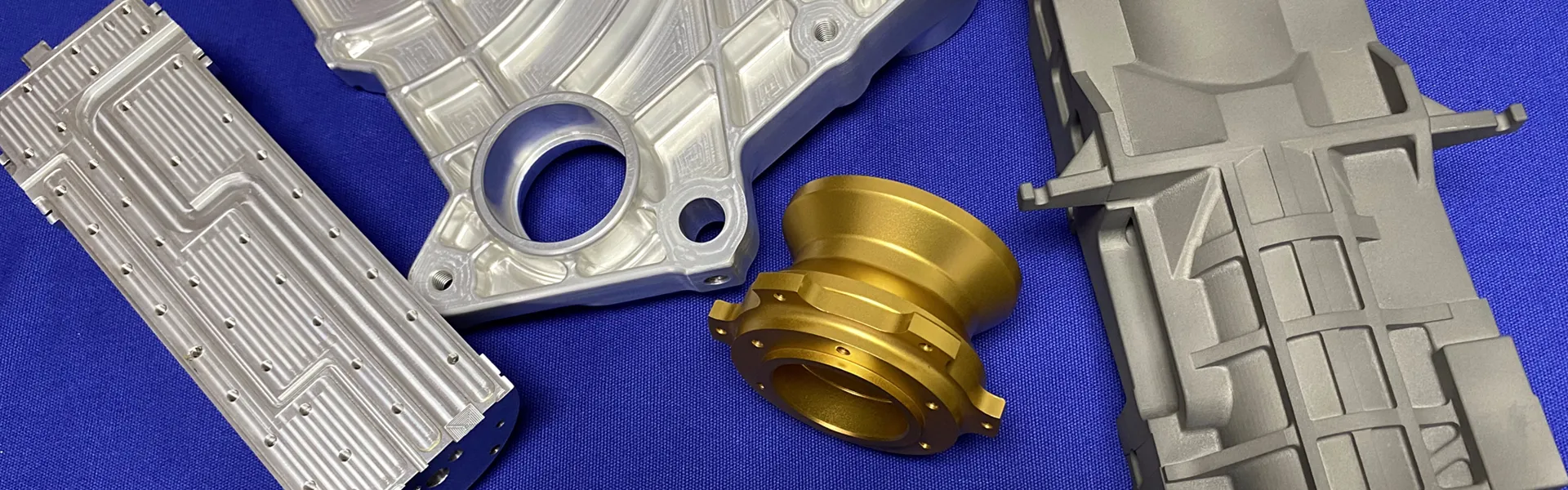

Precision CNC Machined Parts for Demanding Industries

At Falcon CNC Swiss, we specialize in manufacturing precision CNC machined parts that meet the exacting standards of the world's most demanding sectors. Falcon combines advanced material knowledge and precision manufacturing capability to create maximized solutions to your industry specifications. Our high volume CNC production processes are built to meet the rigorous specifications of your industry, which makes us the most trustful cnc machining parts supplier.

| Industry | Critical Applications | Material Solutions | Manufacturing Excellence |

| Automotive & EV | Transmission components,

sensor mounts, baterry enclosures | Aluminum 6061, Copper alloys,

Engineering plastics | High-volume production capabilities,

automated inspection, lean manufacturing |

| Medical & Dental | Surgical instruments,

implantable devices,

diagnostic equipment | Stainless Steel 316L,

Titanium Grade 5, PEEK | Cleanroom manufacturing,

medical-grade finishing, full traceability |

| Electronics & Telecom | RF enclosures, heat sinks,

connector components | Aluminum 6063, Copper C11000,

EMI shielding alloys | Precision CNC machining for thin-walled

components, thermal management expertise |

| Robotics and Automation | Robotics components,

hydraulic manifolds, sensor mounts | Steel 4140, Stainless Steel 303,

Aluminum 2024 | Large batch machining, rapid prototyping,

custom finishing options |

| Energy and Semiconductor | Valve bodies parts,

pump components, wafer handling parts | Stainless Steel 316,

Aluminum 6061, PPSU | Ultra-clean manufacturing, corrosion-resistant

finishes, high-pressure testing |

From automotive to semiconductor manufacturing, our expertise delivers critical components. Explore our specialized solutions across all sectors: View Our Industry Applications.

Advanced Material Capabilities: From Aluminum to Exotic Alloys

Our expertise extends across a wide spectrum of materials, enabling us to be your ideal CNC machined aluminum parts factory and more. We provide DFM (Design for Manufacturability) guidance to help select the most cost-effective and performance-optimized material for your custom CNC machined parts, ensuring functionality and manufacturability are in perfect balance.

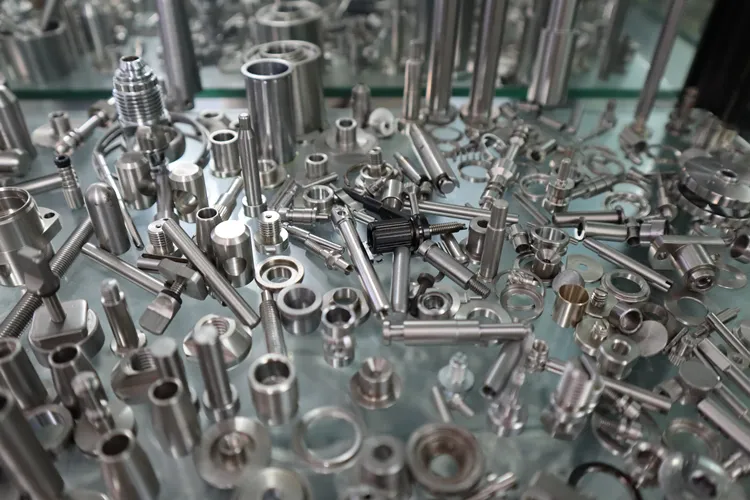

We expertly machine a wide variety of materials that meet your material application specifications:

Aluminum Alloys (6061, 7075, 2024): Perfect for light weight parts and electronic enclosures

Stainless Steels (303, 304, 316, 416): Great for corrosion applications and medical use

Copper Alloys: Excellent thermal and electrical conductivity for custom heat sinks and electrical applications

Engineering Plastics (PEEK, Delrin, ULTEM) : Excellent electrical insulation and chemical resistance

Exotic Alloys (Titanium, Inconel): For extreme temperature and strength specifications

Explore our complete material portfolio and capabilities to find the perfect fit for your project: View Our Full Material Range

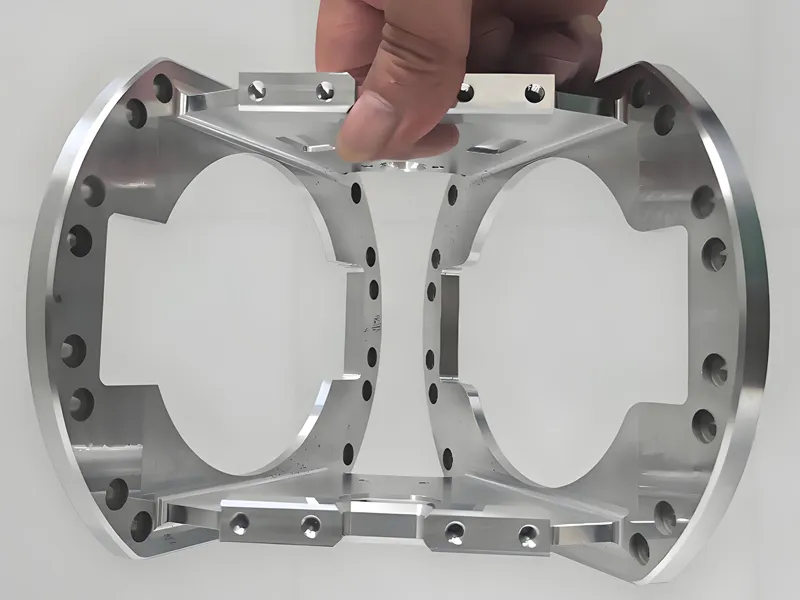

Precision Machined Parts Manufacturer for Multiple Industries

High volume production means repeatable quality and dependability for your part requirements:

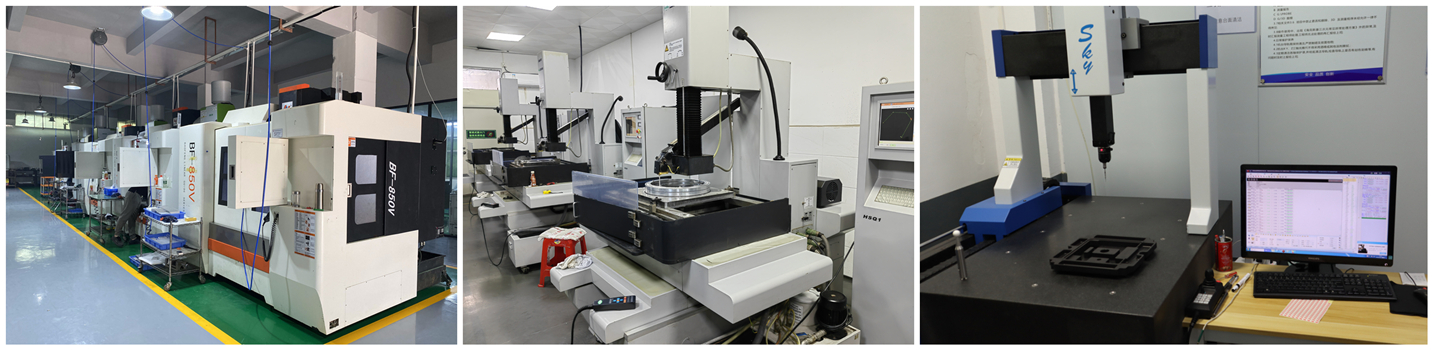

Automated Machining Cells: Robotically integrated cells for continuous production

Quality Monitoring: Full statically monitored SPC record followed by CMM validation

Volume scaling: Prototype to a production volume of 1000,000+

Technical Support: DFM consultation and engineering guidance through production and design

If you require precision CNC components for a high-precision medical application, or high volume production for automotive applications, we have the material knowledge and manufacturing resources to provide long-term value!

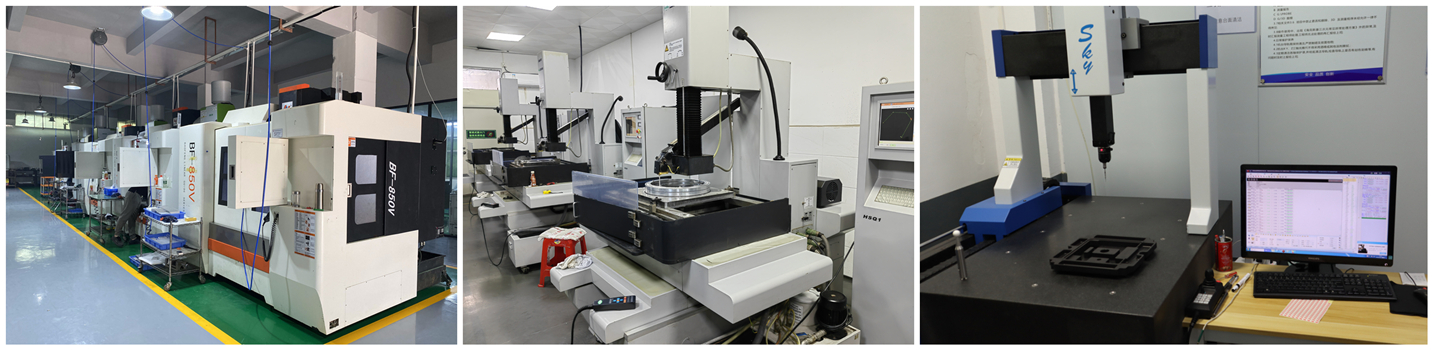

Why Partner with a China-Based CNC Machined Parts Manufacturer?

Choosing Falcon CNC Swiss as your China CNC machined parts partner combines competitive advantage with uncompromised quality. We deliver more than just cost-effectiveness; we offer a stable, vertically integrated supply chain, significant technical expertise, and rigorous quality systems. As a leading CNC precision machined parts manufacturer, our ISO-certified processes and advanced machine park ensure consistent, high-volume output. Our bilingual engineering team provides seamless communication and proactive support, turning the challenge of offshore sourcing into a reliable extension of your manufacturing operation.

1.Superior Industry Knowledge & Experience

Tapping into decades of specialized experience and knowledge in high volume precision machining, our team provides you with excellent Design for Manufacturability (DFM) recommendations to create your parts with better performance and cost.

2. Comprehensive Capabilities Overview on Falcon Machined Parts Supplier

| Capability Category | Specific Strengths | Your Benefit |

| Technical Expertise | • DFM analysis and optimization

• Value engineering services

• Advanced machining techniques | Reduced production costs by 15-30%

while improving component reliability |

| Equipment and Technology | • 300+ CNC machines

• Multi-axis milling centers

• Automated production cells | Consistent quality across production runs and

reduced manufacturing costs |

| Quality Assurance | • ISO 9001, 16949, 13485

• Full traceability systems

• Statistical process control | Reliable components that meet strict quality

standards and documentation requirements |

| Production Capacity | • Dedicated production lines

• Flexible scaling options

• Vendor-managed inventory | Scalable solutions from prototype to production

volumes of 100,000+ units |

| Customer Support | • Dedicated project management

• Transparent communication

• Proactive problem-solving | Smooth project execution with single-point

contact and technical support |

3. Commitment to Quality & Reliability

Our quality system challenges us to ensure all parts meet these extreme conditions:

First article inspection and in-process quality assurance

Full documentation including material certifications

Real-time monitoring and control systems for quality

98.5% on-time delivery rate for all orders

4. Supply Chain Solutions

We provide supply chain solutions with supply chain supply:

Effortless international logistics expertise and shipping

Mitigation of risk for availability

Lean Continuous Improvement programs

Preferred customer partnerships with pre-planned scheduling

Get Your Custom CNC Machined Parts Quote: A Simple 4-Step Process

Ready to leverage our custom CNC part manufacturing capabilities for your project? Whether you need a single prototype or have a high volume quote request, our streamlined process ensures clarity and efficiency from start to finish.

Submit Your Design & Requirements

Upload your 3D CAD files (STEP, IGES, X_T, etc.) and provide key details such as material preference, quantity (from prototype to high-volume), and any post-processing needs.

Expert Design Review & Technical Consultation

This is where we add value. Our engineers conduct a complimentary DFM (Design for Manufacturability) analysis. We’ll provide a technical consultation with actionable feedback to optimize your part for cost, performance, and manufacturability.

Receive Your Transparent, Detailed Quote

You will receive a comprehensive quote outlining costs, lead times for prototyping and testing or full production, and material options. No hidden fees.

Approve & Launch Production

Upon your approval, we immediately schedule your order on our advanced CNC machining centers. For prototypes, we focus on speed; for production runs, we activate our optimized high-volume workflows.

Have a complex project? Contact us directly for a personalized technical consultation to kickstart your prototyping and testing phase today. Request a free quote now!

CNC Machined Parts FAQ: Answers for Engineers & Buyers

1. What kinds of CNC machined components do you have capabilities for?

We have capabilities to create precision CNC machined parts including: impellers, enclosures, heat sinks, manifold blocks, brackets, spline shafts, and mold pins for aerospace, automotive, and medical applications.

2. What materials can you machine?

We can machine aluminum, stainless steel, titanium, copper, and brass, as well as engineered plastics, such as PEEK and Delrin, for strength, weight, and environmental considerations.

3. What is your typical production volume capabilities?

We support the development of prototypes through to high volume production, from one part to millions, with reliable and consistent quality.

4. How do you implement quality within CNC machined parts?

We have an ISO 9001 certified quality system which has first article inspection, in-process checks, statistical process control, as well as full dimensional verification using CMM equipment.

5. What industries do you provide CNC machined parts to?

We supply precision machine components to the aerospace, automotive, medical, energy, semiconductor, and industrial automation industries.

6. Do you offer design support?

Yes, we offer DFM (Design for Manufacturability) analysis that is free of charge to maximize the design, performance, cost, and manufacturability of your parts.

7. What is your lead time for production work?

Typical production lead times are 2-4 weeks based on order quantity and complexity. We also offer expedited services when required.