Aluminum CNC Milling Service & Aluminum CNC Milling Parts

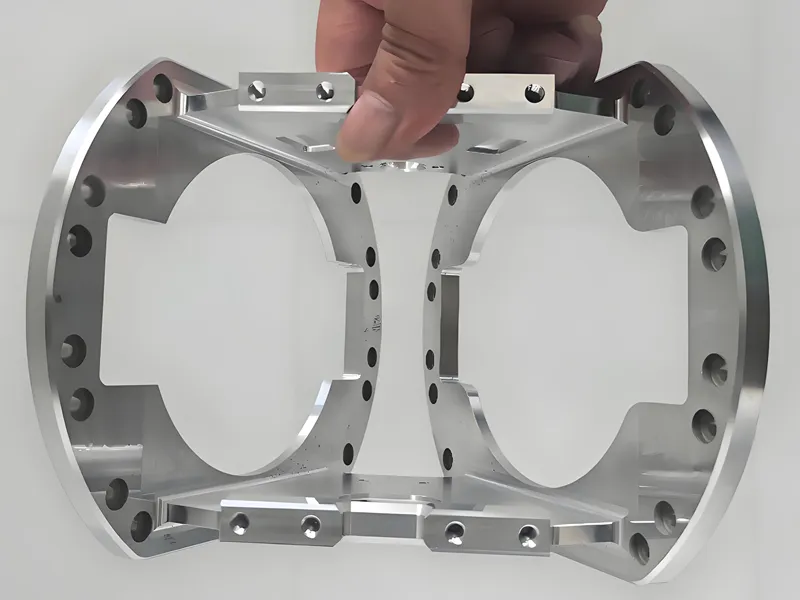

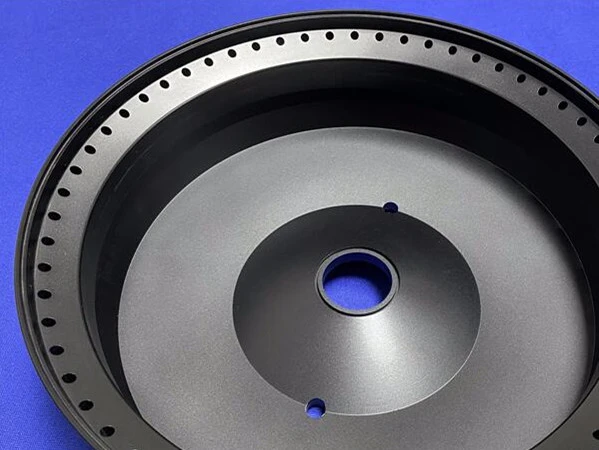

Falcon CNC Swiss is a trusted provider of aluminum CNC milling service, manufacturing high-quality aluminum CNC milling parts for lightweight and high-strength applications.

Common aluminum grades we machine include:

Aluminum 6061 / 6061-T6

Aluminum 7075

Aluminum 5052

As a professional aluminum CNC milling parts factory, we ensure excellent surface finish, precise tolerances, and consistent quality across every production run.

CNC Milling Parts Supplier & Manufacturer in China

As a reliable CNC milling part supplier and CNC milling parts manufacturer in China, we support global customers with competitive pricing, strict quality control, and on-time delivery.

Advantages of Falcon CNC Swiss:

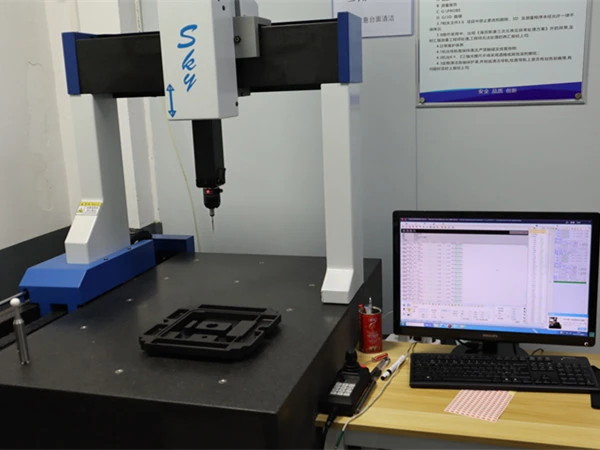

Professional CNC milling parts factories with advanced equipment

Experienced engineering and quality inspection teams

Stable supply chain and fast production lead times

Global shipping and responsive technical support

We are committed to delivering precision CNC milling parts that meet international standards and customer expectations.

"Falcon CNC Swiss milled 15,000 aerospace-grade aluminum heat sinks for our satellite systems. Their 5-axis capabilities and ISO 9001 documentation cut our QA time by 40%, ensuring on-time delivery for a NASA subcontract."

– Michael Carter, Lead Engineer

A high Technology Company

"Start Your Precision Project Now – Upload CAD for a Free DFM Analysis & 24-Hour Quote →"

Get Instant Pricing

FAQ – CNC Milling Services & Custom Milled Parts

Q: What complex geometries can your 5-axis mills handle?

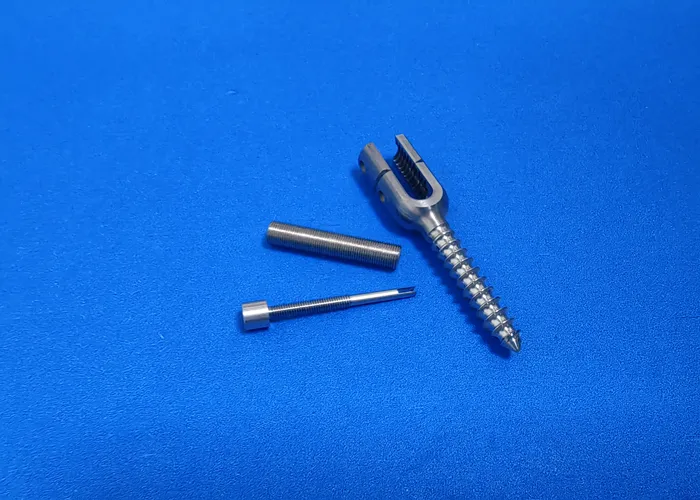

A: Our 5-axis machines produce organic contours (e.g., titanium implants), undercuts, and deep cavities with ±0.001" positional accuracy.

Q: Can you mill flame-retardant plastics like Ultem®?

A: Yes. We optimize spindle speeds and coolant flow for Ultem® 2300 and PEEK to prevent delamination and achieve Ra 0.8µm finishes.

Q: How fast can you deliver prototypes?

A: Most prototypes ship in 3-5 days, including DFM feedback and optional anodizing/bead blasting.

Q: Do you support large-format milling for aerospace parts?

A: Our mills handle parts up to 650mm x 500mm, ideal for aerospace brackets, drone frames, and satellite heat sinks.

Q: What types of CNC milling services do you offer?

A: We provide precision CNC milling services, including custom CNC milled parts, aluminum CNC milling service, and OEM CNC milling machining parts.

Q: Are you a CNC milling parts manufacturer or supplier?

A: We are both a CNC milling parts manufacturer and supplier, operating our own CNC milling parts factory in China.

Q: Can you support custom CNC milling projects?

A: Yes, we specialize in customized CNC milling services based on drawings, samples, or specific technical requirements.