OEM CNC Turning Parts & Custom Solutions

We offer full OEM support for OEM CNC turning parts, from prototype development to mass production. Our engineering team works closely with customers to optimize designs, materials, and machining processes. As a reliable CNC turned parts factory, we support custom drawings, samples, and technical specifications to deliver tailored CNC turning solutions.

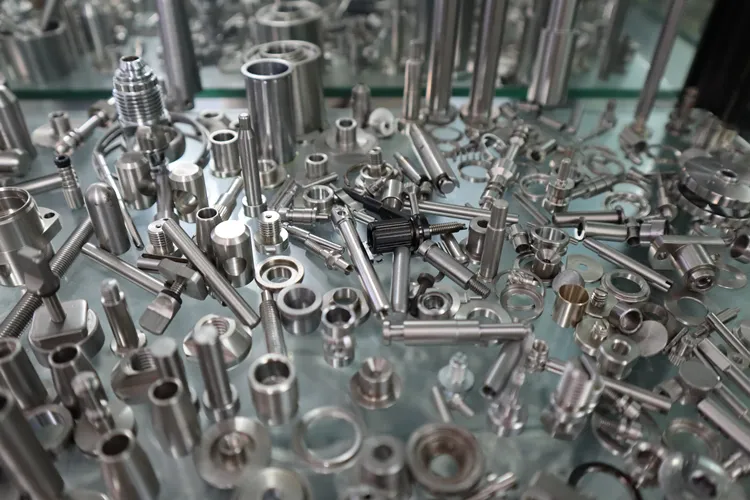

CNC Turning Parts by Material – Aluminum, Brass & Stainless Steel

Falcon CNC Swiss manufactures high-precision CNC turning parts from China using aluminum, brass, and stainless steel to meet different functional and industry requirements. As a professional CNC turning parts manufacturer and supplier, we provide stable OEM CNC turning parts with tight tolerances, excellent surface finish, and consistent batch quality. Whether you are sourcing aluminum CNC turning parts, working with reliable brass CNC turned parts suppliers, or looking for durable stainless steel CNC turning parts from China, our CNC turning center delivers cost-effective and precision-driven solutions for global customers.

Material Options for CNC Precision Turning Parts

| Material Type | Common Grades | Key Advantages | Typical Applications |

| Aluminum CNC Turning Parts | 6061, 6061-T6, 7075 | Lightweight,

corrosion-resistant,

excellent machinability | Electronics housings,

automotive components,

structural parts |

| Brass CNC Turned Parts | C360, C377, C260 | Excellent machinability,

high conductivity,

smooth surface finish | Electrical connectors,

fittings, valves,

precision inserts |

Stainless Steel

CNC Turning Parts | SUS303, SUS304, SUS316 | High strength,

corrosion resistance,

durability | Medical devices,

food-grade components,

industrial equipment |

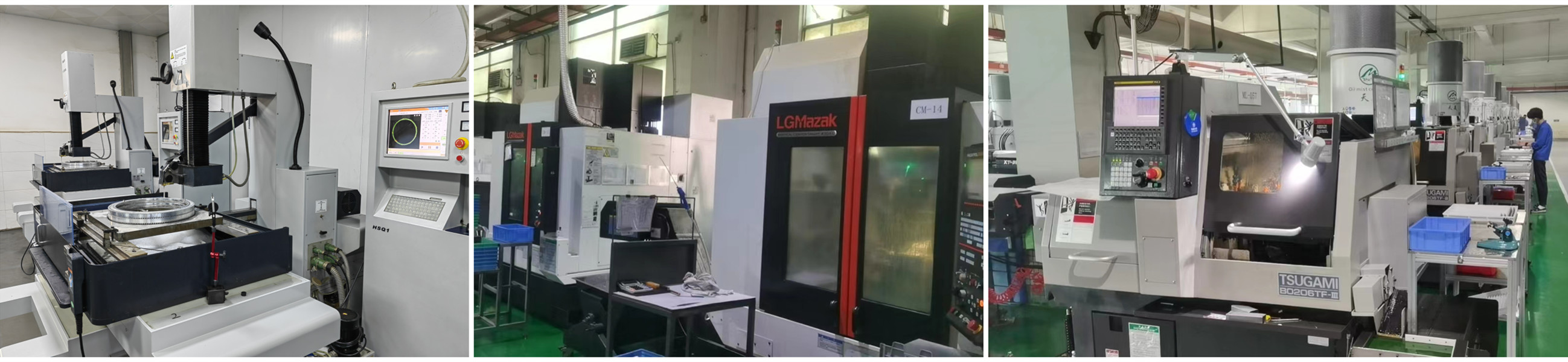

Why Choose Our CNC Turning Parts Factory in China

Reliable brass CNC turned parts suppliers and in-house manufacturing

Precision CNC turning parts China production with strict quality control

Support for low-volume prototypes and high-volume OEM orders

Consistent quality across aluminum, brass, and stainless steel CNC turned parts

When tolerances matter, experience and process control make the difference. Get Engineering Support for Your Parts.

"Falcon’s team delivered 15,000 titanium spinal screw prototypes with integrated Wire EDM threads. Their ISO 13485 compliance and full material traceability accelerated our FDA approval by 4 weeks."

– Dr. Sarah Lin, Biomedical Engineer,

A Precision Solutions Company

FAQ – CNC Turning Service & Precision Turning Parts

Q1: What industries do your CNC turning services support?

A: We focus on automotive (fuel injectors, sensor housings), industrial (hydraulic valves, pump shafts), and medical (surgical tool handles) sectors.

Q2: What is the maximum diameter and length you can turn?

A: Our CNC turning centers handle parts up to 6" diameter and 24" length, with bar feeder support for high-volume orders.

Q3: Can you machine hardened materials like Inconel?

A: Yes. We use ceramic inserts and high-pressure coolant (1,000 psi) to turn Inconel 718, 17-4PH stainless steel, and other heat-resistant alloys.

Q4: Do you provide surface finishing options?

A: In-house finishes include electropolishing (Ra 0.4µm), anodizing (Type II/III), and passivation for corrosion resistance.

Q5: How do you maintain consistency in high-volume runs?

A: Automated SPC (Statistical Process Control) monitors tool wear and dimensional accuracy, ensuring ±0.005mm tolerances across batches of 250,000+ units.