As a trusted and economical CNC fittings manufacturer based in China, we utilize a documented and step-by-step approach to build precision CNC fittings and custom connectors in all materials including aluminum, brass, and titanium.

We evaluate the engineering drawings or 3D models that you submit to us, to determine feasibility and assist our clients in designing the best custom CNC fittings for their application.

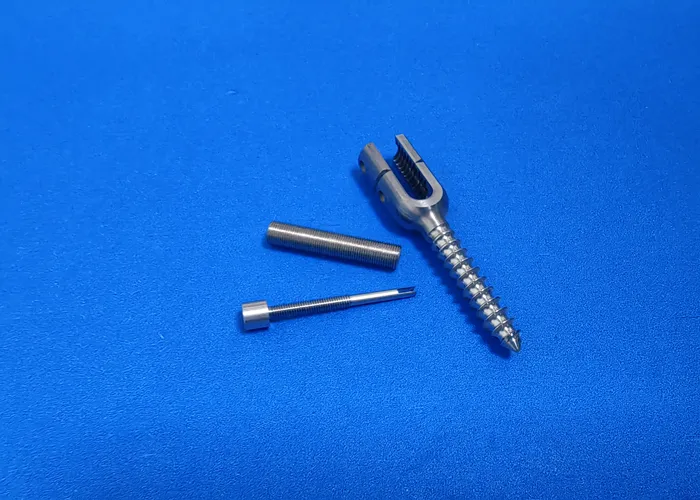

We only utilize raw materials that are certified to the highest standards. We use titanium for high-strength fittings, brass for electrical connectors, and aluminum for lightweight industrial applications. As a aluminum connectors manufacturer, we make sure every single part is made from materials that are certified to international standards.

Swiss CNC Turning & Milling

Components are machined to the tolerances of ±0.001” on new, state-of-the-art Swiss CNC lathes. As a Swiss machining fittings manufacturer, we can manufacture exceptionally high-precision and complex custom brass connectors and CNC milled connectors for demanding industries.

Surface Treatment and Inspection

All components have deburring, coating and plating finishes applied and are fully inspected at 100% before they leave us. Whether you require polished medical-grade parts or titanium fittings that are corrosion resistant, we guarantee it will be quality work.

Custom Connector Fittings Designed for Your Industry

At Falcon CNC Swiss, we know that some industries require unique specifications for their connector fittings depending on their usage. We offer fully custom connector fittings to suit your exact needs, whether that is for hydraulic applications, automotive applications, medical devices or industrial machinery.

Our expert engineering team will work with you to design and manufacture fittings to your specifications in dimensions, pressure ratings and materials. Using our CNC Swiss machining technology, we can guarantee that your custom connector fittings are built with precision, durability and reliability.

Some notable benefits of our custom connector fittings are:

| Feature | Description |

| Precision Machining | Tolerances as tight as ±0.005 mm |

| Material Options | Stainless steel, brass, aluminum, plastic |

| Pressure Ratings | From low-pressure hydraulic to high-pressure industrial standards |

| Surface Finishes | Anodizing, plating, polishing as required |

| Industry Standards | ISO, SAE, ASTM, and custom certifications |

Request a Quote for your Custom Fittings

If you are looking for custom connector fittings and hydraulic fittings manufacturer, a precision CNC fittings manufacturer, or a Swiss machining fittings supplier, we provide fully customized, tolerance-critical components with fast lead times and global support. Get a Free Quote Now!