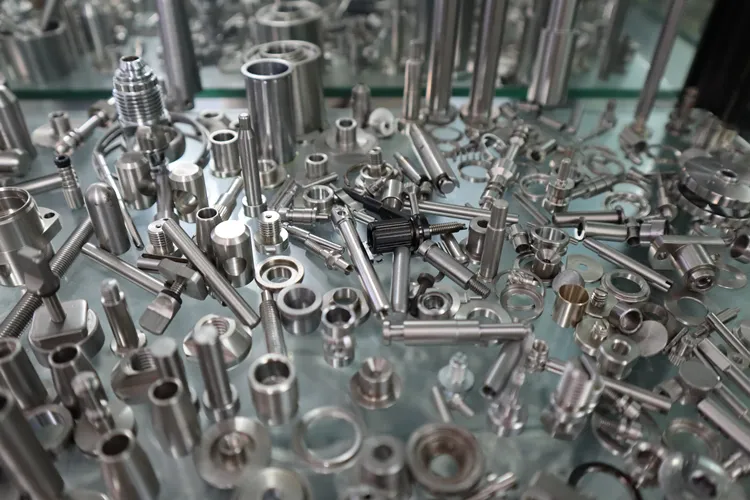

Reliable OEM CNC Machining Manufacturer & Supplier

As a trusted OEM CNC machining manufacturer, we provide end-to-end precision machining suppliers solutions. From initial design consultation (DFM) to final delivery, our team integrates seamlessly with your workflow. We understand the needs of a precision manufacturing company serving global markets, offering industry-specific solutions that enhance your supply chain reliability, cost-efficiency, and time-to-market for Swiss machine products and beyond.

Below is a breakdown of our expertise across critical sectors:

| Industry | Key Materials | Processes | Case Study | Key Benefits |

| Medical | Titanium (Grade 5, 23), PEEK, 316L Stainless Steel | Swiss Machining, 5-Axis Milling | 10,000+ orthopedic bone screws with Ra 0.2碌m surface finish | Biocompatibility, ISO 13485 compliance |

| Automotive | 6061 Aluminum, 4140 Steel, Brass | CNC Turning, Multi-Axis Milling | 50,000 fuel injector nozzles (+-0.005mm tolerance) | High thermal resistance, IATF/ISO certified |

| Industrial | Inconel 718, Delrin, Copper C110 | CNC Milling, EDM Wire Cutting | 2,500 hydraulic valve bodies for heavy machinery | Corrosion resistance, IP67 sealing capability |

| Electronics | Ultem 2300, Magnesium AZ31B | Micro-Machining, Laser Cutting | 100,000 heat sink enclosures for IoT devices | EMI shielding, lightweight & compact designs |

Our expertise extends across these and other high-tech sectors. To explore our full range of specialized manufacturing solutions for your industry, visit our dedicated page: Explore Industry-Specific Capabilities.

Material & Process Compatibility: Engineering for Success

Precision begins with the right match. Our expertise is encapsulated in a strategic Material-Process Compatibility Matrix, a cornerstone of our high precision machine shop capabilities. This systematic approach guarantees that every material – from aluminum and stainless steel to engineering plastics – is paired with the optimal CNC milling, turning, or Swiss machining process. This maximizes performance, longevity, and cost-effectiveness for your precision machining parts.

| Material Category | Optimal Processes | Key Characteristics & Applications |

| Aluminum Machining | High-Speed CNC Milling & Turning | Excellent machinability and strength-to-weight ratio. Ideal for lightweight enclosures, heat sinks, and structural components in electronics and automotive. |

| Brass and Copper Machining | Swiss Screw Machining, Precision Turning | Superior electrical/thermal conductivity and natural corrosion resistance. Perfect for connectors, valves, and RF components. |

| Stainless Steel Machining | Swiss Machining, 5-Axis Milling, Hard Turning | High strength and corrosion resistance. Used for medical instruments, marine hardware, and food-grade parts requiring durability. |

| Titanium Machining | Swiss Machining with Specialized Coolants | Exceptional strength-to-weight ratio and biocompatibility. Critical for aerospace fasteners and medical implants. |

| Plastics Machining | Precision CNC Turning & Milling | Electrical insulation, low friction, and chemical resistance. Used for insulators, bearings, and seals in sensitive environments. |

Selecting the optimal material-process pair is key to project success. For detailed specifications and properties of each material, explore our comprehensive resource: Visit Our Material Selection Guide

High-Capacity Precision Manufacturing for Volume Demands

We provide low-volume custom CNC machined parts for prototypes or high volume precision CNC machined parts for production for consistent accuracy manufacturing of machined parts every time utilizing Swiss screw machines and multi-axis centers.

As a valued precision cnc machining manufacturer, we have extensive experience with quick-turn prototyping and mass production. For companies with no MOQ, we offer 5 days lead times on custom CNC milled parts to help shorten their product development cycles via our precision CNC precision machining service.

We can support high-volume projects utilizing our automated bar feeders and in-house secondary processes (e.g., passivation and anodizing). For example, we produced 2,000,000 precision aluminum sensor housings for EV manufacturers with ±0.005mm tolerances for all batches, utilizing our CNC Swiss machining experience.

High Capacity CNC & Swiss Machining for Volume Production

Falcon precision machining inc can deliver high volume CNC and Swiss machining projects, again, accurately and consistently with very rapid speed. We use production systems specifically designed for mass production of small complex parts in the medical, automotive, aerospace, and electronics industries.

Scalable Machining Services

300+ CNC and Swiss-type machines for production operations 24/7. Check our Equipment & Process Capabilities →

Multi-axis capabilities to produce complex geometries.

Robotic and bar feed capabilities can maintain production state continuity.

Batch sizes: 100 to 1 million+ parts/month.

Precision Tolerance Repeatability

Tolerance control: ±0.0005" (±12.7μm).

Inline measurement/quality.

ISO and company specific process control.

Economic mass production of OEM parts

Cost optimized production for low-to-high volume production.

Lowest spend setup time and ability to reuse tooling allow for cost lessening for both the short-run and long-run.

Dedicated production line for parts we build on a regular basis.

Secondary operations; plating, heat treating, laser engraving.

Certifications & Quality Control

Quality is non-negotiable. As an ISO 9001, 13485, and 16949 certified CNC machining China OEM parts manufacturer, we adhere to strict protocols for medical and automotive sectors. Every batch undergoes CMM inspection using Brown & Sharpe equipment, with reports available upon request. Our ITAR-registered facility ensures compliance for defense projects, while material certifications and full traceability are standard. Statistical process control (SPC) minimizes deviations, and our zero-defect policy includes free rework or replacement for non-conforming parts.

International Certifications & Compliance

Quality Management: Certified under ISO 9001 for consistent quality management systems.

Medical Excellence: ISO 13485 certified, adhering to stringent standards for medical device manufacturing.

Automotive Standards: IATF 16949 compliant, meeting the specific requirements of the automotive industry.

Material & Environmental: Full RoHS & REACH compliance, with material certifications and full traceability for every batch.

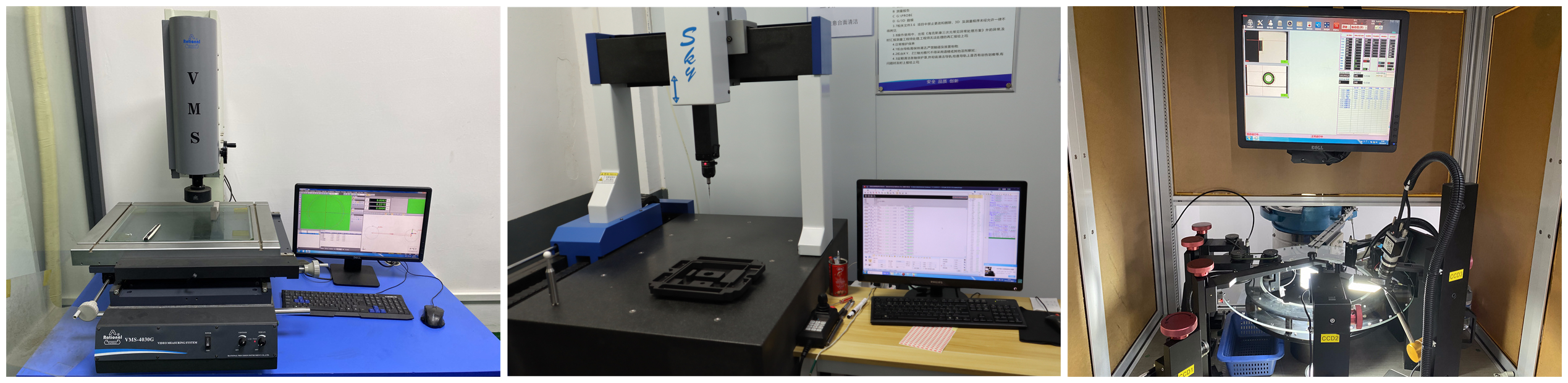

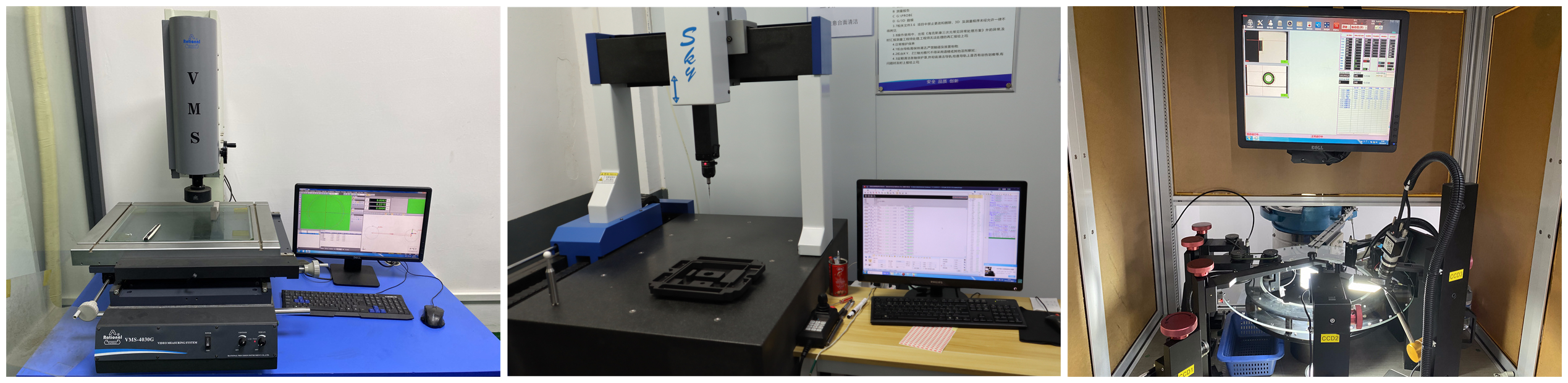

Advanced Inspection & Measurement

Precision Verification: First-article and batch inspections conducted with Brown & Sharpe Coordinate Measuring Machines (CMM) for micron-level accuracy.

Surface & Form Analysis: Utilization of optical comparators and profilometers to verify surface finishes, contours, and complex geometries.

Statistical Control: Implementation of Statistical Process Control (SPC) to monitor production in real-time, proactively minimizing process deviations.

"Falcon CNC Swiss machined 15,000 titanium spinal implant prototypes for our FDA submission, achieving 0.005mm concentricity across all units. Their material traceability documentation cut our audit prep time by 60% – a true OEM CNC machining manufacturer in regulated manufacturing."

– Dr. Emily C, Lead R&D Engineer

OEM Medical

Ready to Partner with a Leading Precision Machining Expert?

Ready to elevate your next project with Swiss-grade accuracy? Our ISO-certified engineers are here to optimize your design for manufacturability, cost, and speed.

✅ Instant Quote in 24 Hours

✅ DFM Analysis Included

✅ No MOQ Prototyping

Connect with Falcon CNC Swiss today. Let’s discuss how our comprehensive capabilities as a precision cnc machine shop can bring accuracy, reliability, and efficiency to your next project.

Commonly Asked Questions (FAQ)

1. What kinds of materials can you machine for impellers?

We machine a variety of impeller materials: aluminum (lightweight, cost-effective); stainless steel (corrosion resistant); titanium (high strength-to-weight ratio), and engineering plastics (chemical resistant). The material you select will depend on the requirements of your application (e.g., pressure, temperature, compatibility with fluids).

2. What is your usual tolerance for precision turned components?

Our typical hold tolerances are ±0.0005 inches (0.0127 mm) for critical dimensions on precision turned components. Tighter tolerances can be held based on part design and material.

3. Do you perform surface treatment or finishing services?

Yes, we offer complete finishing services, including anodizing (for aluminum), passivation (for stainless steel), plating, polishing, and painting for durability and corrosion resistance, as well as aesthetic properties.

4. Can you accommodate high-volume production orders?

Absolutely. We have automated CNC cells and processes that accommodate high-volume production while providing high-quality and on-time delivery.

5. How do you provide quality control for CNC machined parts?

We maintain a rigorous quality control process that involves a first article inspection (FAI), in-process checks, SPC monitoring program for inspection capabilities, and final dimensional verification using CMM and optical measurement equipment.

6. What markets do you support?

Our OEM precision machining service supports the medical and automotive, semiconductor, energy, medical markets, and industrial automation markets and others.

7. What is your lead time for prototype orders?

Our standard lead times for prototypes range from 5-10 business days, based on complexity and materials available. We also offer expedited options.