Ready to Utilize Falcon’s Swiss Machining Facility?

If you are looking for an engineering facility specializing in Swiss machining, Swiss machine shop capabilities and precision Swiss screw machined parts, then Falcon CNC Swiss provides superior service and quality, as well as global coverage.

Accelerate your production with Swiss machining expertise tailored to your industry’s strictest standards. Whether prototyping or scaling to 100,000+ units, we deliver:

⚡ 6-Hour Rapid Quotes – Submit your CAD file by 10 AM, receive pricing by 4 PM.

⚡ Material-Specific DFM Feedback – Optimize designs for titanium, PEEK, or exotic alloys.

⚡ Dedicated Compliance Support – Full documentation for FDA, IATF 16949, or RoHS.

How We Enhanced Quality and Communication

"Falcon CNC Swiss produced 80,000 aluminum LiDAR sensor housings for our autonomous vehicle project. Their AI-driven toolpath optimization reduced machining time by 25%, and the anodized finish passed salt spray testing for 1,000+ hours. Seamless PPAP documentation saved us 3 weeks in OEM approvals."

– Michael T, Senior Manufacturing Director

A Mobility Systems

Contact us to request samples or a custom quote today! Upload Your Design & Get Started →

Swiss Machining FAQ

Q1: What materials can be machined using Swiss screw machining?

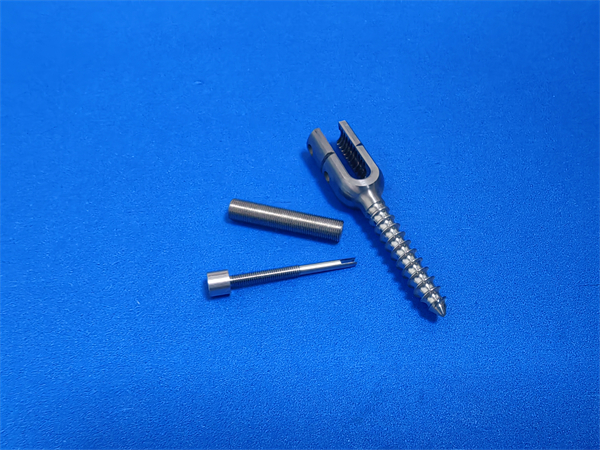

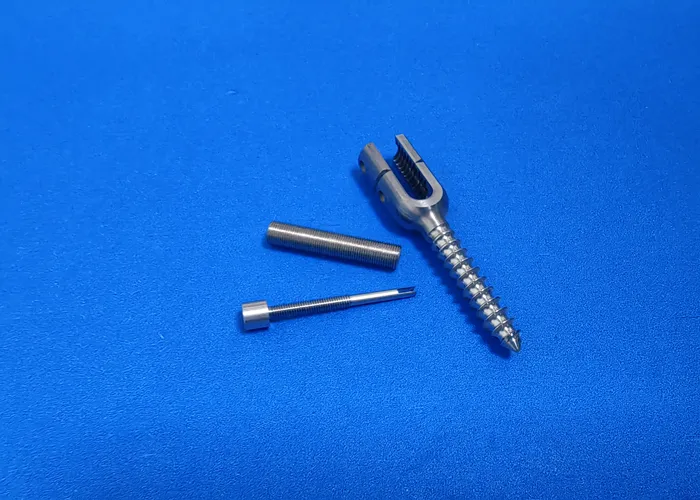

A: We specialize in medical-grade metals like titanium Grade 5/23 and 316L stainless steel, as well as engineering plastics such as PEEK and Ultem®. These materials are ideal for implants, micro-connectors, and FDA-compliant devices.

Q2: What tolerances can your Swiss machines achieve?

A: Our 7-axis Swiss lathes consistently deliver ±0.0002" tolerances, even for parts as small as 0.5mm diameter (e.g., hypodermic needle guides).

Q3: Do you offer cleanroom packaging for medical components?

A: Yes. Medical parts are machined in ISO Class 8 cleanrooms and vacuum-sealed with anti-static packaging to meet FDA and ISO 13485 requirements.

Q4: Can Swiss machining handle internal features like micro-threads?

A: Absolutely. Our live tooling and subspindle integration allow us to machine M0.6 threads and internal slots as narrow as 0.1mm without secondary operations.

Q5: How do you ensure material integrity for implants?

A: We perform XRF spectroscopy to verify alloy composition and ASTM F2129 testing to validate corrosion resistance for implantable devices.