4 Types of Swiss Screw Machines and How They Work

Swiss screw machines, also known as Swiss lathes or Swiss-type lathes, are specialized machines used in precision machining. These machines are designed to handle small, complex parts with tight tolerances. There are several types of Swiss screw machines, each with its own unique characteristics and capabilities.

1. Mechanical Swiss Screw Machines:

These machines are older and rely on mechanical means to control the cutting tools. The machine's cam-driven mechanism moves the material to be cut to the tool. This machine's main advantage is that it can handle more significant diameter parts than other Swiss screw machines.

2. CNC Swiss Screw Machines:

These machines use computer numerical control (CNC) technology to control the cutting tools. CNC Swiss machines can handle very small diameter parts and can produce complex geometries with high precision and accuracy. CNC Swiss machines can use live tooling, which enables them to perform milling, drilling, and tapping operations in addition to turning.

3. Hydromat Rotary Transfer Machines:

These machines are capable of simultaneous machining of multiple parts. They feature a rotary indexing table with multiple spindles and cutting tools. Parts are fed into the machine and moved through the various machining operations on the indexing table.

4. Automatic Lathe Machines:

These machines use a cam-driven mechanism to control the cutting tools. Automatic lathes are used for high-volume production of simple parts. They are known for their high speed and productivity but lack the flexibility of CNC Swiss machines.

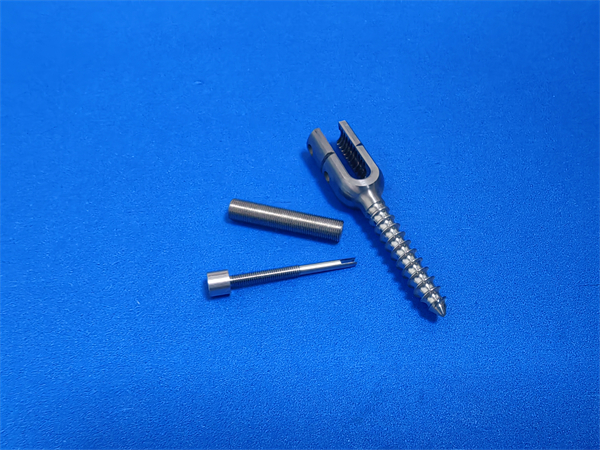

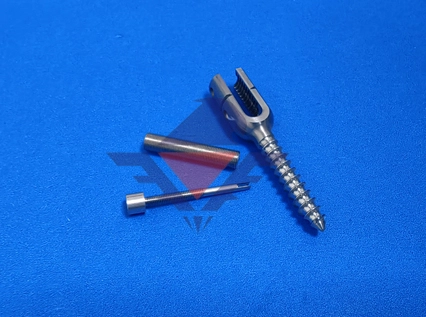

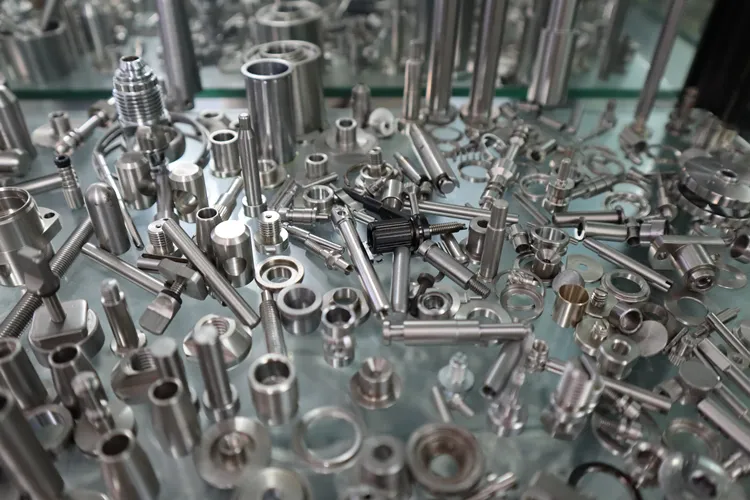

At Falcon Swiss machine shop, most of our machines are automatic multi-spindle Swiss screw machines, which are more accurate and work faster. Our machines are an excellent choice for high-volume production of small, complex parts with tight tolerances, and can offer significant benefits in terms of productivity, precision, versatility, and cost savings.

Welcome to inquiry your precision CNC Swiss machining projects and contact us!