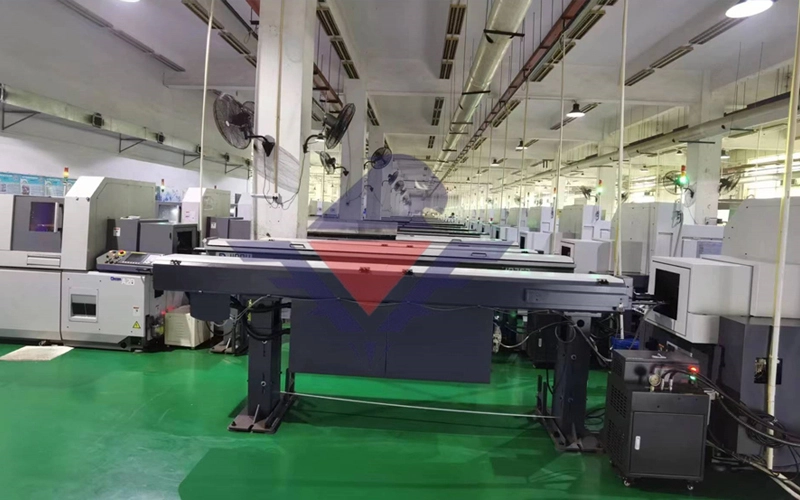

Aerospace Industry Choose Falcon Swiss Turning Machine Shop

For over two decades, Falcon has been delivering the highest quality and most reliable precision parts to the aerospace industry. We pride ourselves on strictly following customer design drawings to ensure that every detail is manufactured in place, resulting in precision parts that meet the rigorous requirements of aircraft manufacturing.

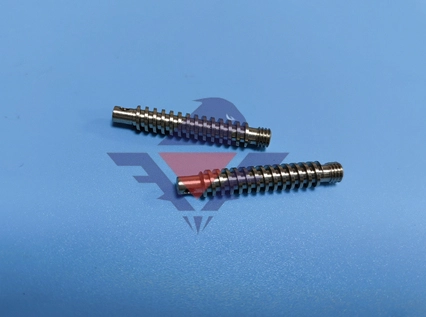

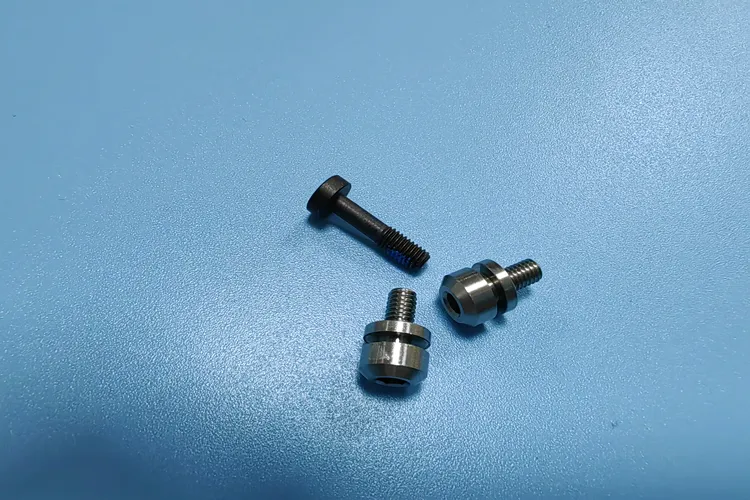

Some swiss turned parts in the aerospace industry:

● Landing gear components

● Shafts

● Pressure sensors

● Temperature sensors

● Flow meters

● Terminals