Industries Served by Our Hydraulic Valves & Coupling Fittings Manufacturing

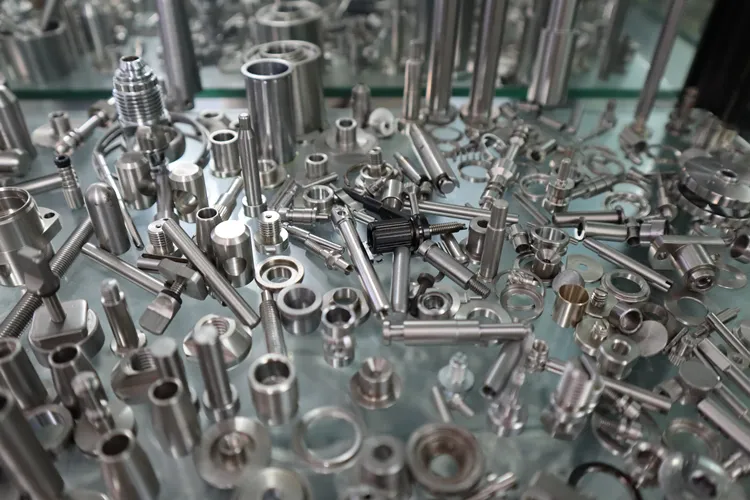

Falcon CNC is a leading hydraulic components manufacturer and coupling fittings supplier and many other industries that require precision fluid controls and strong connection points.

Our products are featured in:

| Industry | Applications |

| Hydraulic Systems | Hydraulic valve blocks, pressure control valves, and high-pressure hose couplings |

| Construction Equipment | Excavators, loaders, and cranes requiring leak-free hydraulic fittings |

| Agricultural Machinery | Tractors, harvesters, and sprayers using quick connect hose fittings |

| Oil & Gas | High-pressure coupling compression fittings and corrosion-resistant valve parts |

| Automotive & Transport | Brake systems, steering hydraulics, and hydraulic valve bodies |

| Aerospace & Defense | Lightweight, high-strength coupling pipe fittings and precision valve components |

From hydraulic fitting manufacturers and OEMs to MRO service providers, Falcon CNC supplies components that are responsible for keeping crucial systems running ware and operating safely and efficiently anywhere in the world. Contact Us Today →

"Falcon delivered 50,000 Inconel 625 fuel line couplings for our hydrogen-powered vehicles. Their cryogenic machining prevented embrittlement at -40°C, and the ITAR-compliant documentation accelerated DOD approvals."

– James Park, Senior Engineer

✓ ITAR-Registered Project

FAQ

Q1: What tolerances are achievable for valve spools?

A: We hold ±0.001mm on spool diameters and 0.005mm cylindricity for smooth operation in hydraulic systems.

Q2: Can you machine anti-vibration couplings?

A: Yes. Delrin® AF couplings with Swiss-machined dovetail grooves reduce NVH by 30% in industrial pumps.

Q3: How do you test valve leak rates?

A: We use helium mass spectrometry and ISO 5208 protocols to certify leak rates<0.1 sccm.