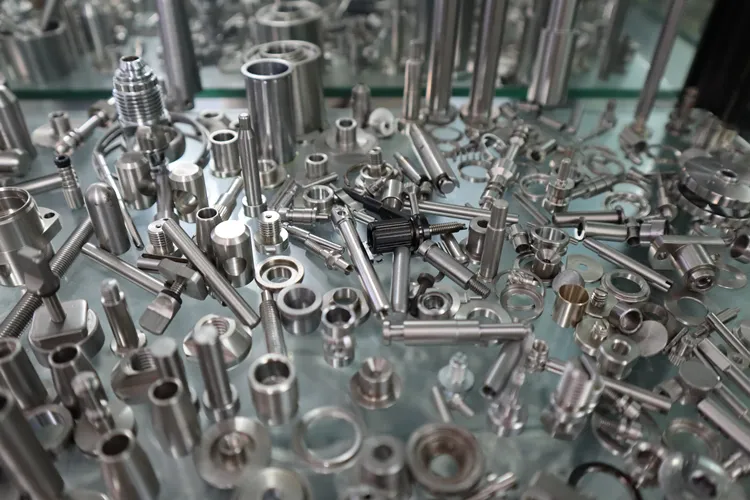

Regardless of industry, Swiss machined components are known for precision, durability, and overall quality around the world. The improvements arc developed as a result of advanced CNC Swiss machining tech and some of the most demanding standards in high-tech industries including, the medical and automotive industries we hope to address the top uses of Swiss machined components in these industries and their importance in their safety and performance.

1. Swiss Machined Components in the Medical Industry

The medical industry strives for parts that are precise, reliable, and biocompatible in the devises they are being utilized in. Swiss machined components will meet all these requirements in applications such as:

Surgical Tools: CNC Swiss machining offers tolerances and complex geometries necessary for surgical instruments or tools, such as scalpels, clamps, and forceps.

Implantable Devices: Medical devices like bone screws, spinal implants, and dental fixtures require materials such as titanium or stainlesss steel that are not only biocompatible but corrosion resistant which allows them to withstand every day use and sterilization from product being inserted into the patient.

Falcon CNC Swiss would be delighted for medical manufacturers to access Swiss machined or precision Swiss machined components with the highest standards of American and or world standards for medical devices. Safety and life of medical devices are critical to the patient.

2. Swiss Machined Components in the Automotive Industry

The automotive industry has some of the greatest stress, temperature, and wear and tear components that are produced by machining. If we think of Swiss machined components, we think precision and reliability.

Falcon CNC Swiss is well-known for its ability to take any concepts, designs, prototypes, or wishes and manufacture both COPQ and OEM quality Swiss machined automotive components with tight tolerances, high volume and quality surface finishes.

3.Why Use Swiss Machined Components?

Swiss machining hands down provides the medical and automotive industries with some superior capabilities:

Material Capabilities: Swiss machining can turn produce using a material list that maybe is some metals typically associated with machined components, which is great because Stainless steel, titanium, brass and aluminum can all be the base material,

Conclusion:

Whether precision fabrication of medical devices or making the precision components for automotive parts development, Swiss machined components are crucial to performance, reliability, and safety. Falcon CNC Swiss prides itself in manufacturing comfort in high quality precision Swiss machined components for the medical and automotive industries.

Please investigate our line of Swiss Machined Components or CNC Swiss machined and ask us how we can make your new design or manufacturing program become a reality with customer service and quality of product that will be substantially superior to industry standards.